A vertical type assembling apparatus for planetary gear

An assembly device and planetary gear technology, which is applied in the direction of positioning device, workpiece clamping device, clamping, etc., can solve the problems affecting the qualification rate, accuracy and service life of the planetary gear system, the accuracy is difficult to guarantee the quality requirements, and the technical ability of workers is high. problems, to achieve the effect of reducing the difficulty of assembly technology and human influence, stable and reliable quality, and low technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

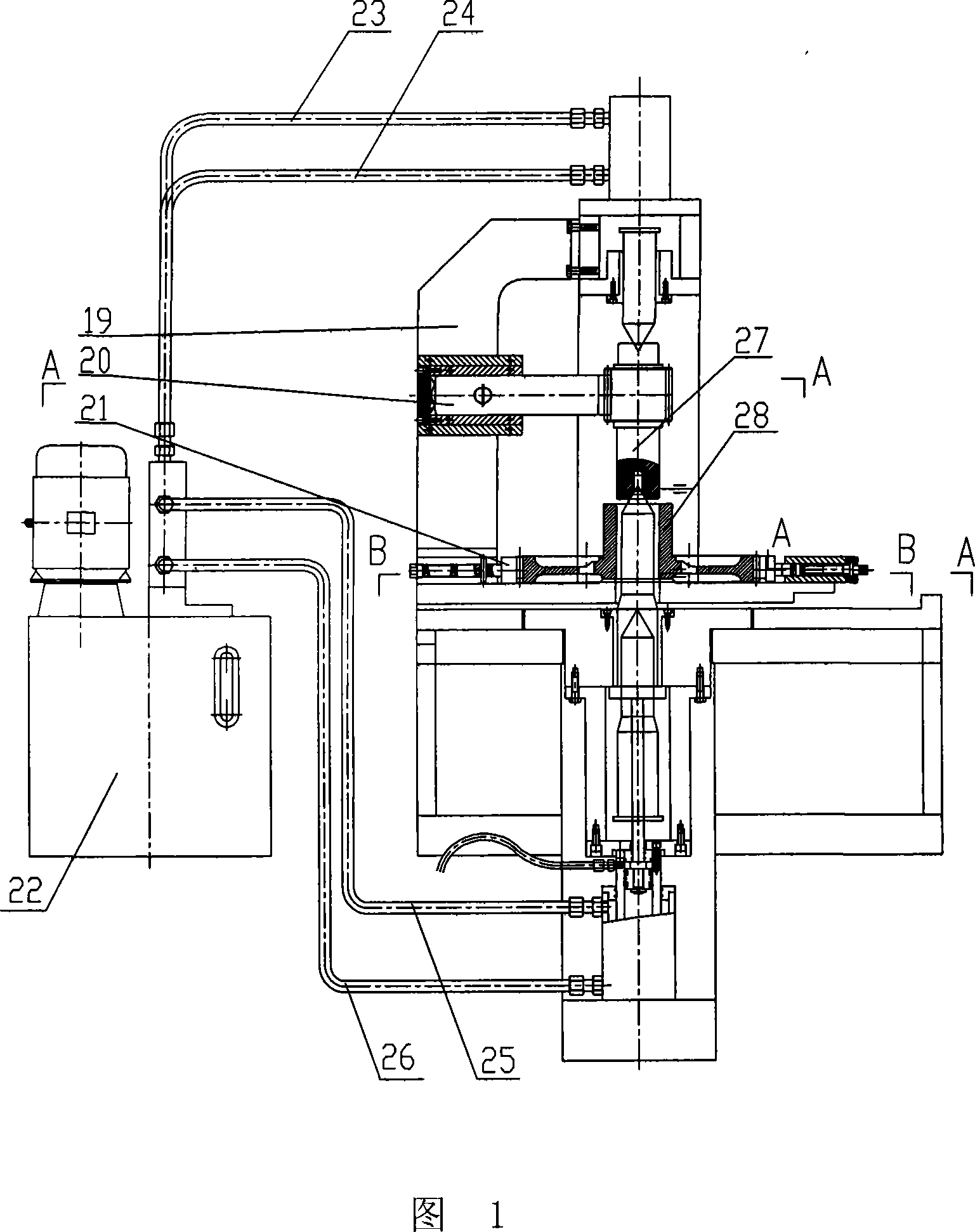

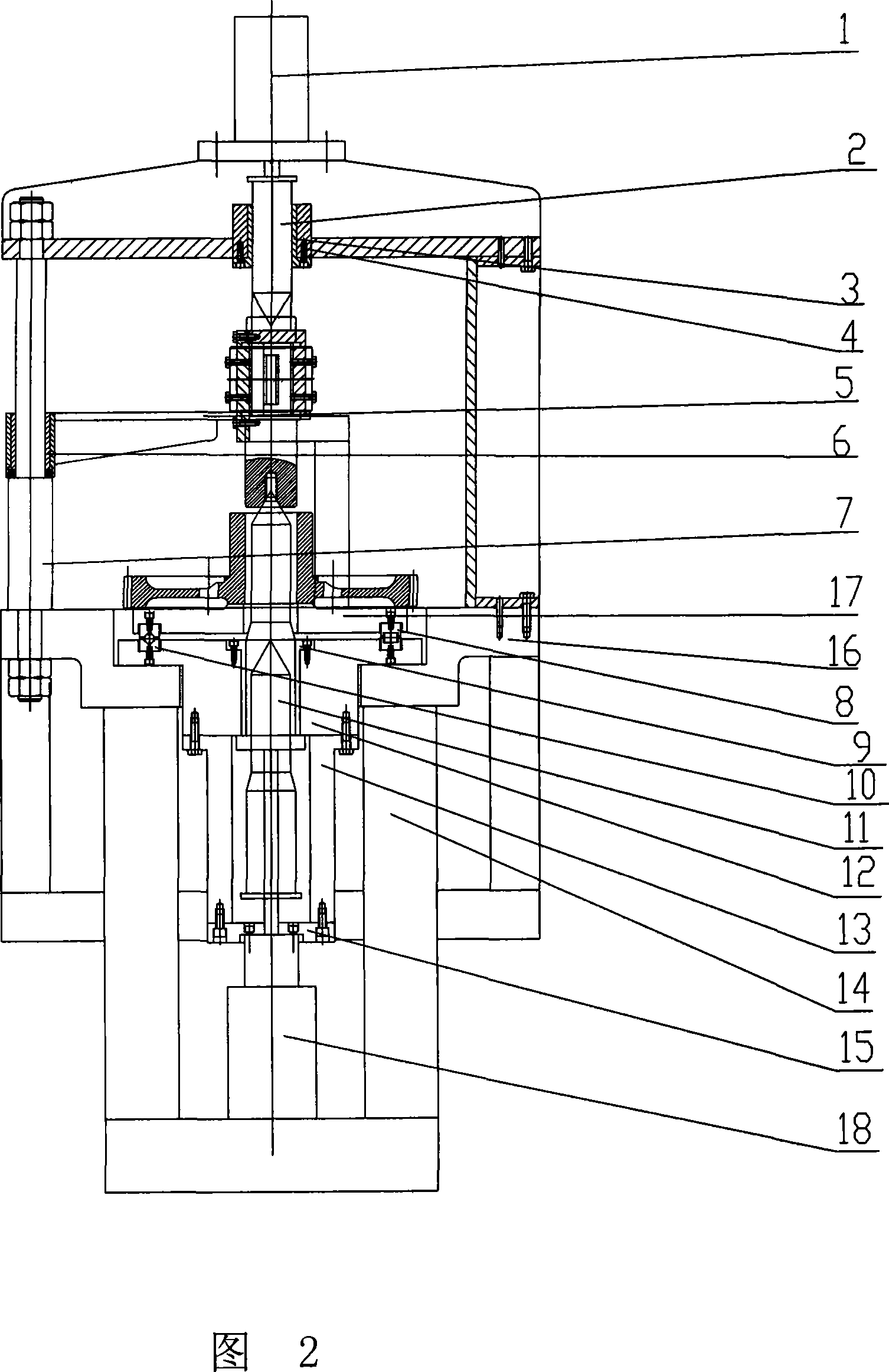

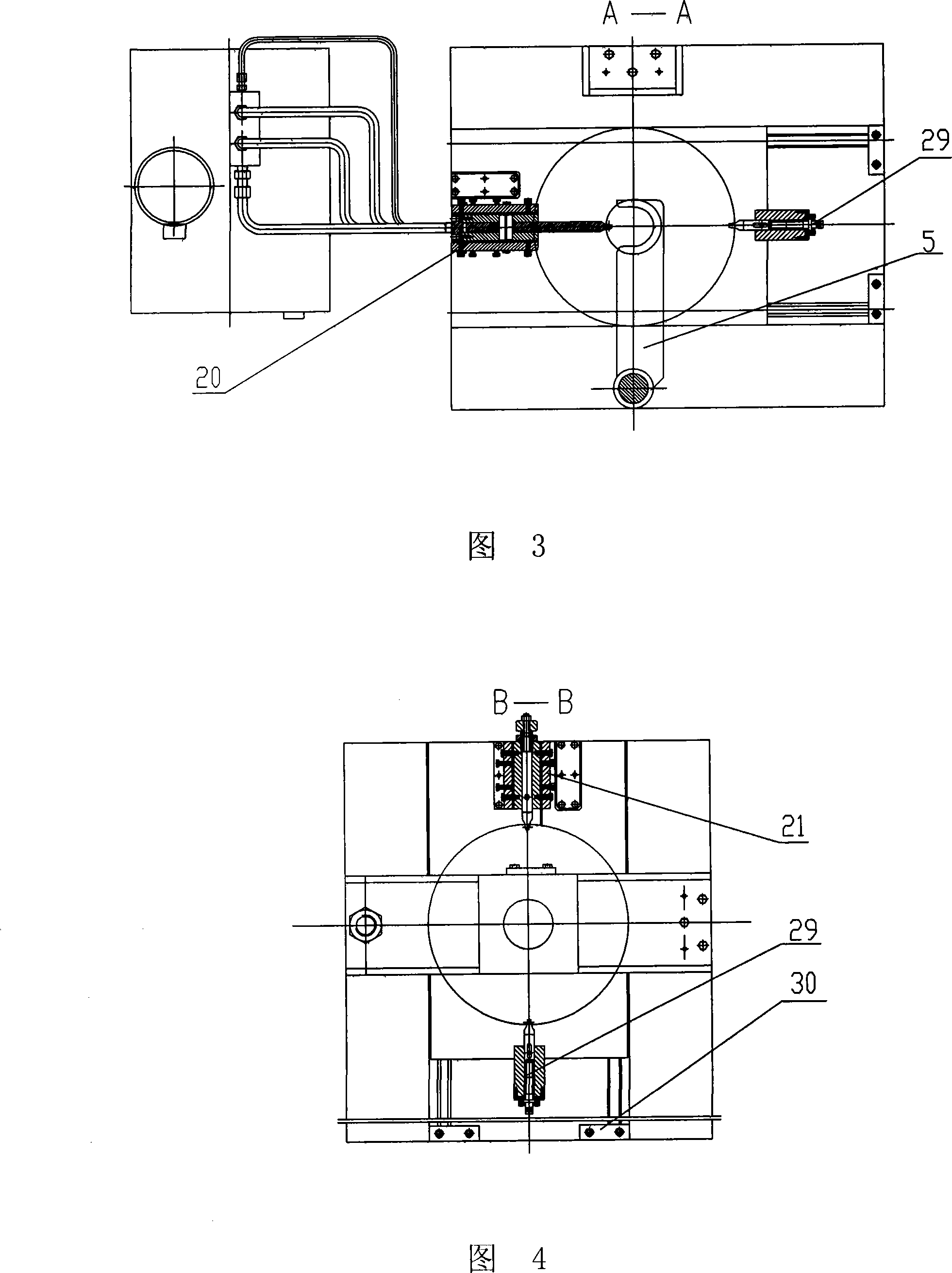

[0022] The views of the planetary gear assembly device described in Figures 1 to 4 describe the internal structural form of the entire device.

[0023] The planetary gear vertical assembly device is composed of a mechanical part, a hydraulic part and an electric control part. The pipelines in the hydraulic part are respectively connected with the upper thimble 2 and the lower thimble 11, and the upper thimble 2 supports the positioning mechanism, and the lower thimble 11 supports the positioning mechanism and is coaxially installed on the angled plate 19 and the base plate 16 respectively; the pinion The positioning plate 20 is installed on the angled plate 19; the movable positioning pin device 29 and the wedge self-locking position device 21 are horizontally installed on the base plate 16.

[0024] The upper thimble 2 supports the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com