Hinge supporting seat of automobile collapsible roof board

A technology of support seat and hinge, applied in the direction of roof, vehicle parts, transportation and packaging, etc., can solve the problems of lack of reinforcement in the B-pillar area, unsatisfactory welding quality, and many parts and components, etc., to achieve simple welding methods and structural Simple, high-quality manufacturing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described below in conjunction with embodiment and accompanying drawing.

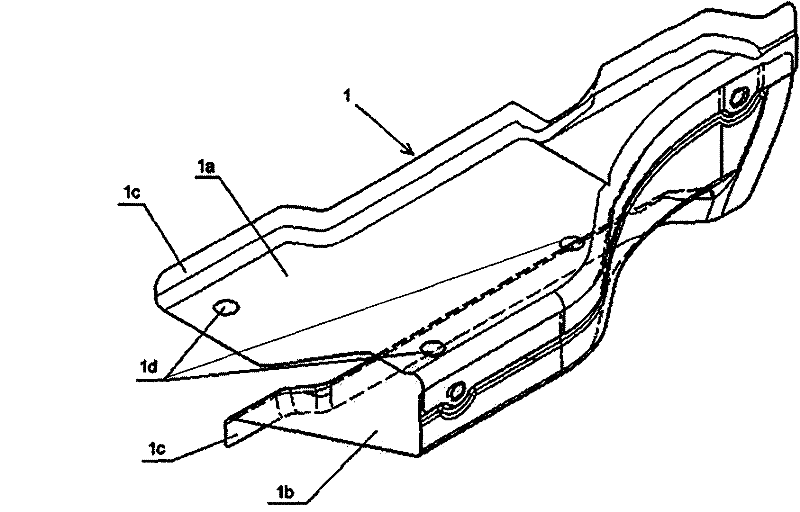

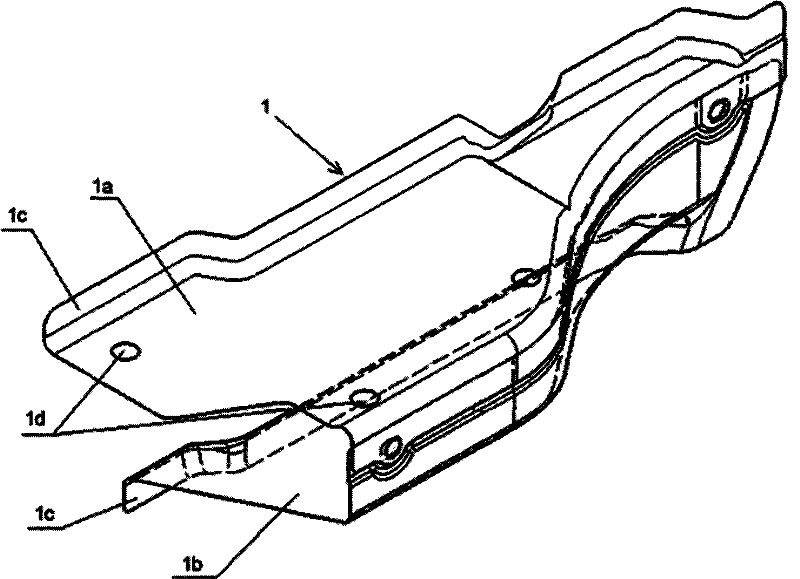

[0013] see figure 1

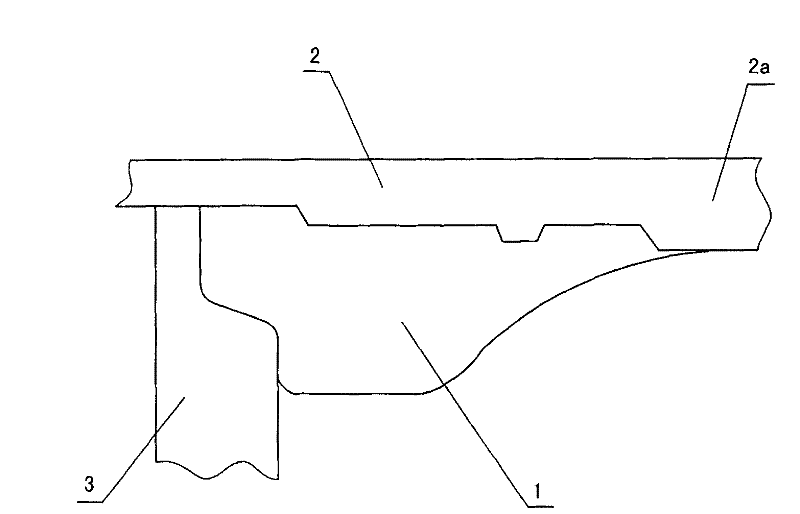

[0014] The hinge support seat of the retractable roof of the automobile is a seat body 1 bent into a frame structure by a sheet material. The cross section of the seat body 1 is approximately "∪" shape, and the width of the seat body 1 is from the rear end to the front end. Through bending and bending, the front end of the seat body 1 is closed and the rear end is open. For the convenience of processing and installation, the seat body 1 of this embodiment is composed of hinge mounting base 1a and reinforcement base 1b connected to each other. The hinge mounting hole 1d is provided on the hinge mounting base 1a, and there are three hinge mounting holes 1d. The hinge of the retractable roof of the automobile can be installed on the seat body 1 through the hinge installation hole 1d. One edge of the seat body 1 has an outwardly bent flange 1c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com