Microchannel module in laser

A technology of micro-channel modules and lasers, applied in lasers, laser devices, laser parts, etc., can solve problems such as reduced efficiency of automated production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described with reference to the accompanying drawings.

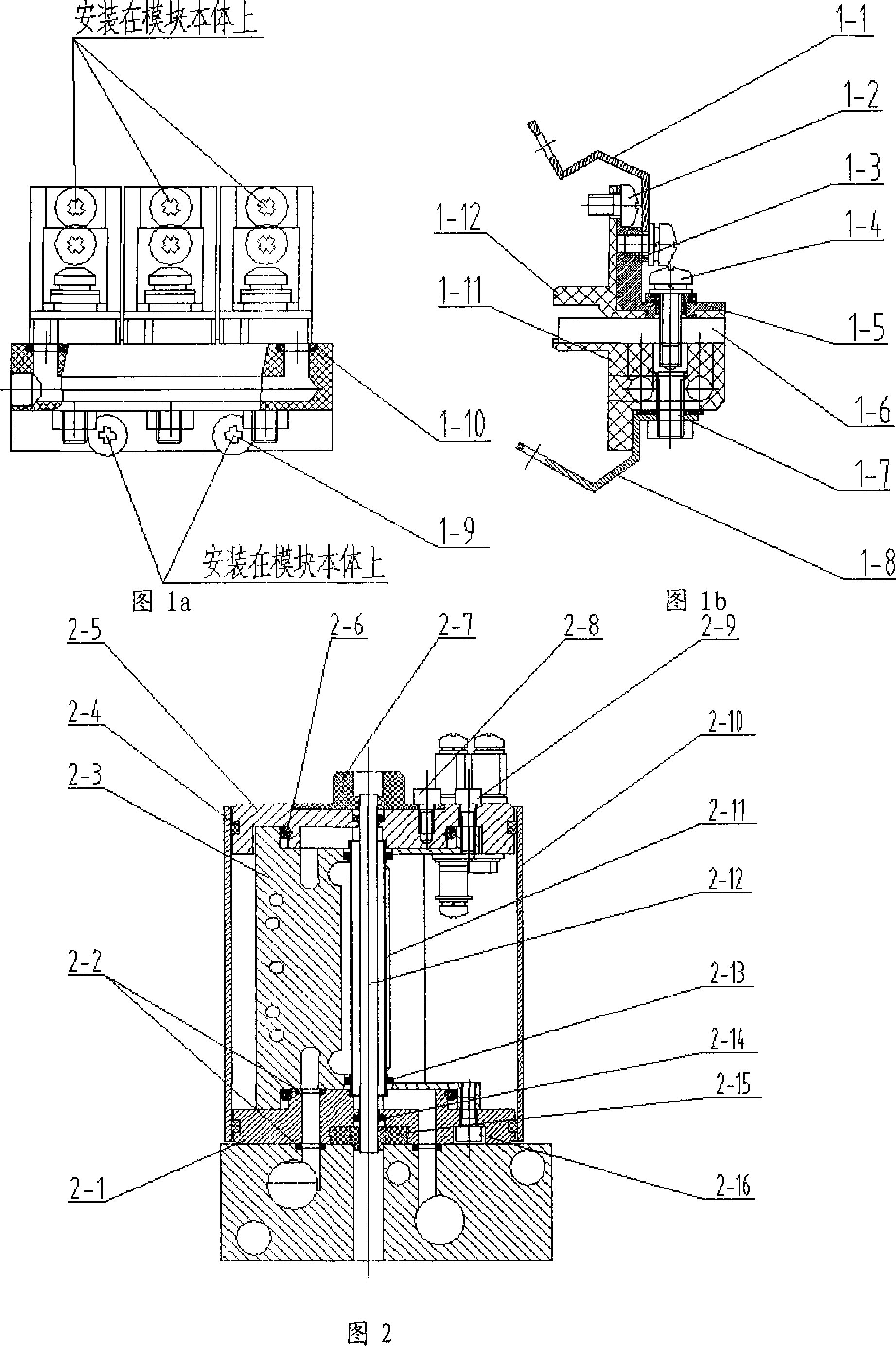

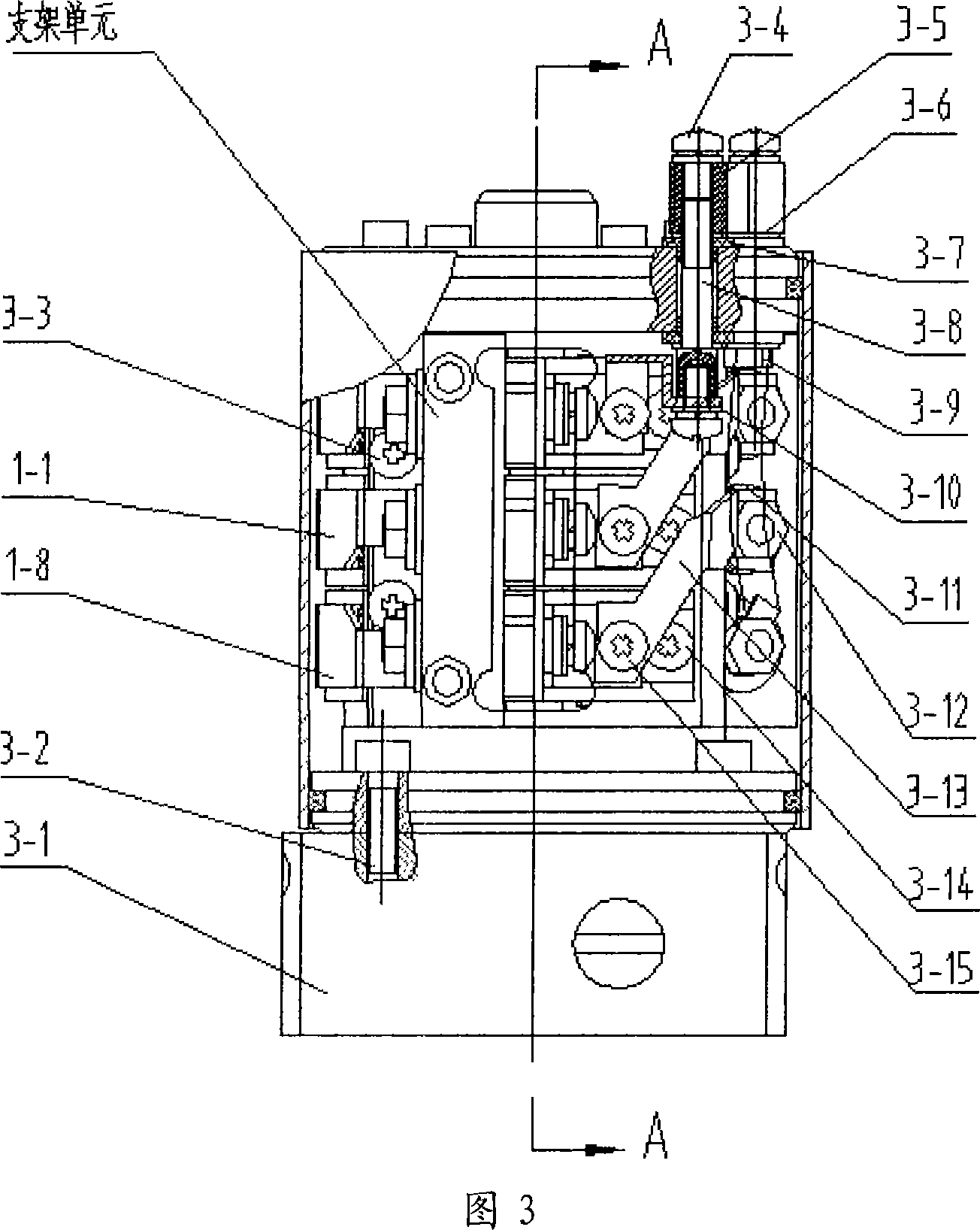

[0012] As shown in Figure 1, the bracket unit includes three sets of bracket components, and the three sets of bracket components are installed on the same bracket at 120 degrees to each other. Each bracket component includes: electrode B1-1, insulating screw 1-2, negative electrode 1- 3. Three combination screws 1-4, insulating washers 1-5, diode module 1-6, positive electrode 1-7, electrode C1-8, three combination screws 1-9, O-ring 1-10, bracket 1- 11. Insulating plates 1-12 and three combination screws 1-4 sequentially fix insulating washers 1-5, negative electrodes 1-3, insulating plates 1-12 and diode modules 1-6 on the brackets 1-11, while the positive electrodes 1-7 Fix the electrode C1-8 on the bracket 1-11, and connect it with the three combination screws 1-4 at the same time. The positive electrode 1-7 and the three combination screws 1-4 jointly fix the parts on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com