Anti-fog refrigeration door and method of making the same

A technology for anti-fog and refrigerated cabins, which is applied in windows/doors, building structures, buildings, etc., and can solve problems such as insufficient tolerance, chemical cracks, increased design and manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

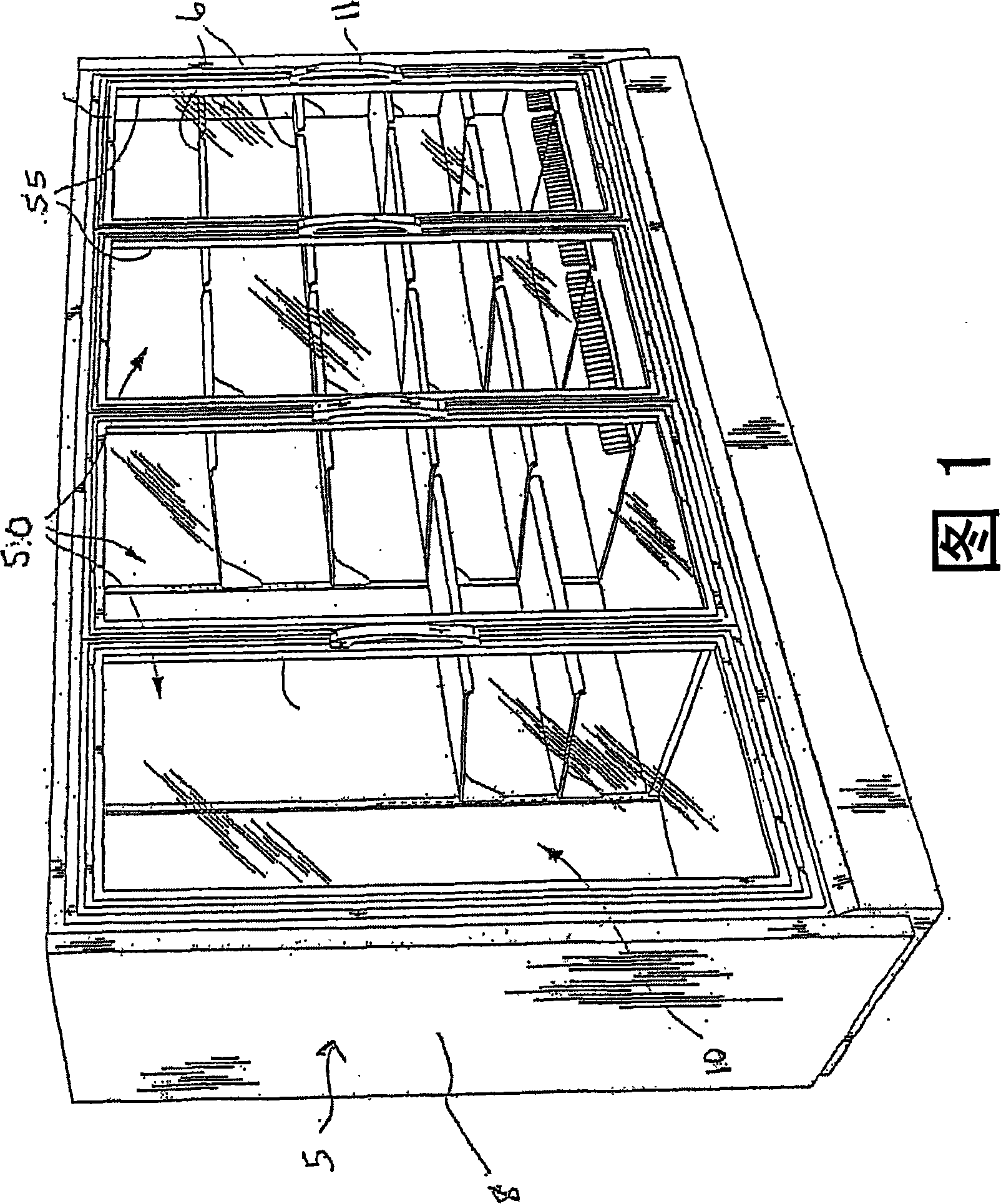

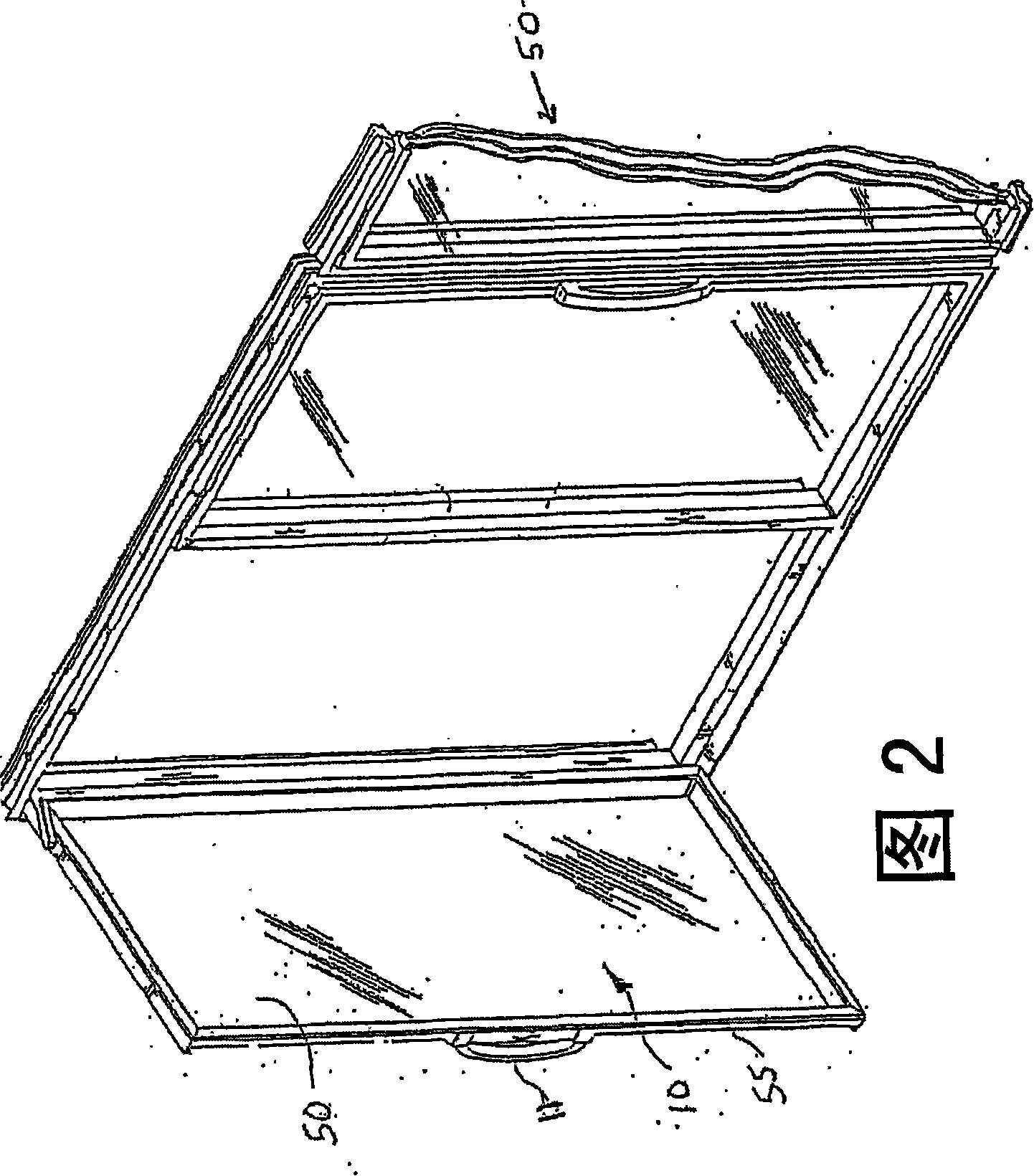

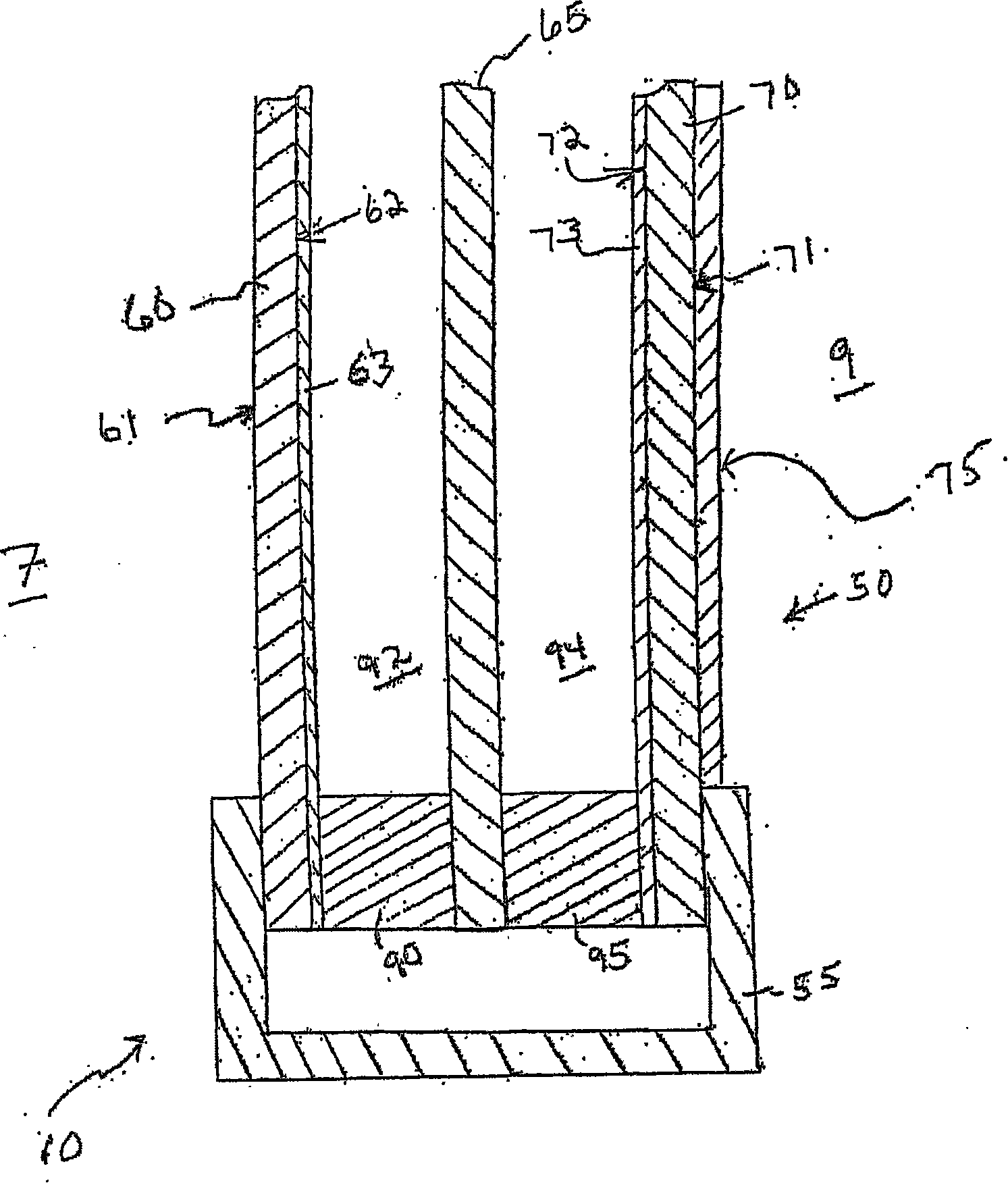

[0042] In the following description, for purposes of illustration and not limitation, specific details are set forth, such as specific coatings, coating processes, sheet and film thicknesses, sealing components, number of sheets, sheet spacing, and assembly methods of the door, etc., thereby providing a thorough understanding of the invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced in other embodiments that depart from these specific details. Descriptions of well-known coatings, coating processes, sealing assemblies, and methods of assembling doors are omitted so as not to obscure the description of the present invention. For the purpose of describing the present invention, terms such as exterior, interior, outside and inside are described according to the direction of perspective from the inside of the refrigerator or compartment, as shown in the accompanying drawings.

[0043] Tests and computer modeling have show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com