Dental restoration special curved surface laser welding method

A special-shaped curved surface and dental repair technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult butt joint, volume shrinkage, shrinkage deformation and other problems in the thermal effect zone of solder joints, and solve the problem of lateral deformation , Solve the effect of false welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The steps of the laser welding method of typical embodiments of the present invention:

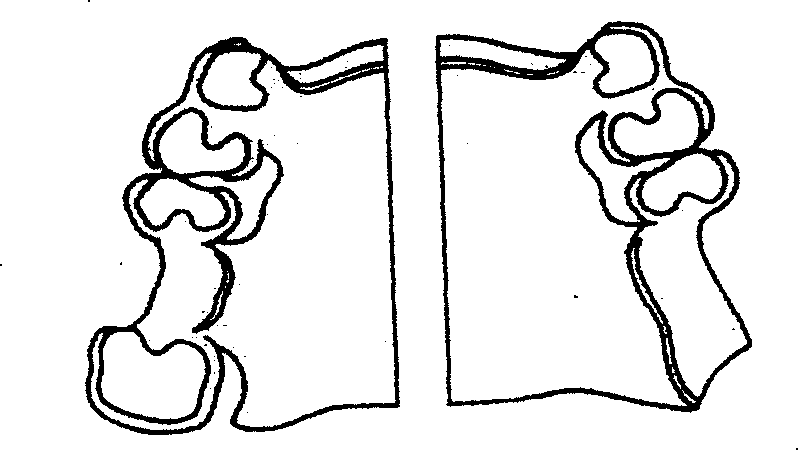

[0022] 1. First, use a sand disc (grinding wheel) to cut a long slit of about 1 mm longitudinally in the middle of the special-shaped surface of the dental restoration to be trimmed, and form two parts, such as figure 1 shown;

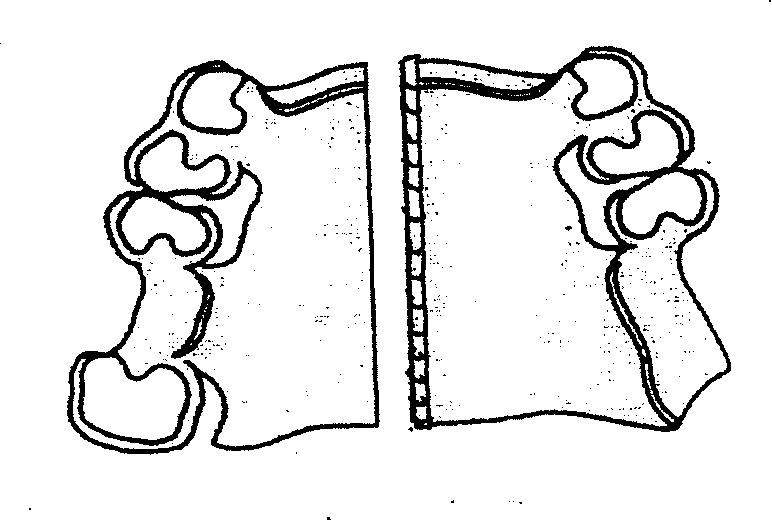

[0023] 2. Put the special-shaped surface of the dental restoration divided into two parts into the dental model (dental restoration model), and clamp them together on the special welding device. First, use a welding wire (drilling chromium alloy welding wire) about 0.5 mm in diameter), placed along the long seam and welded on one side of the long seam, such as figure 2 shown;

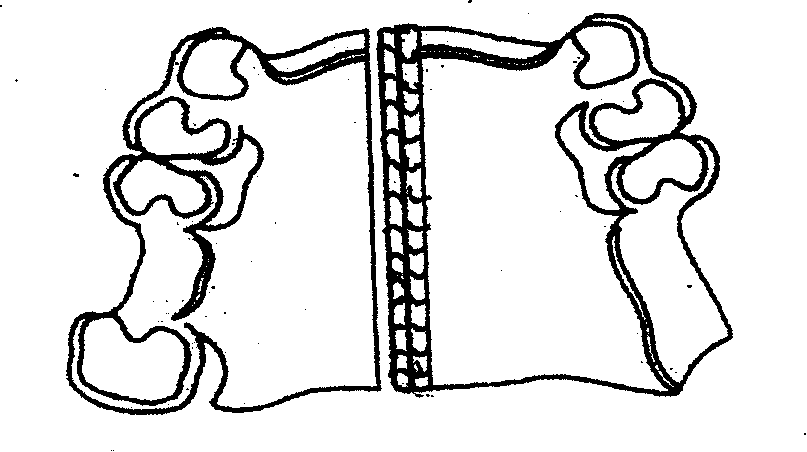

[0024] 3. Also use another same welding wire to weld in parallel on the side of the aforementioned welding wire until the remaining width of the long seam is equal to or less than 0.2mm, such as image 3 shown; because the larger the weld, the more metal to be filled, the greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com