Suspension type construction method of top pipe shaft

A construction method and suspended technology, applied in the field of suspended construction of pipe jacking shafts, can solve the problems of large excavation area, long construction period, building safety threats, etc., so as to reduce the impact on the environment, save support costs, and shorten construction. effect of cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

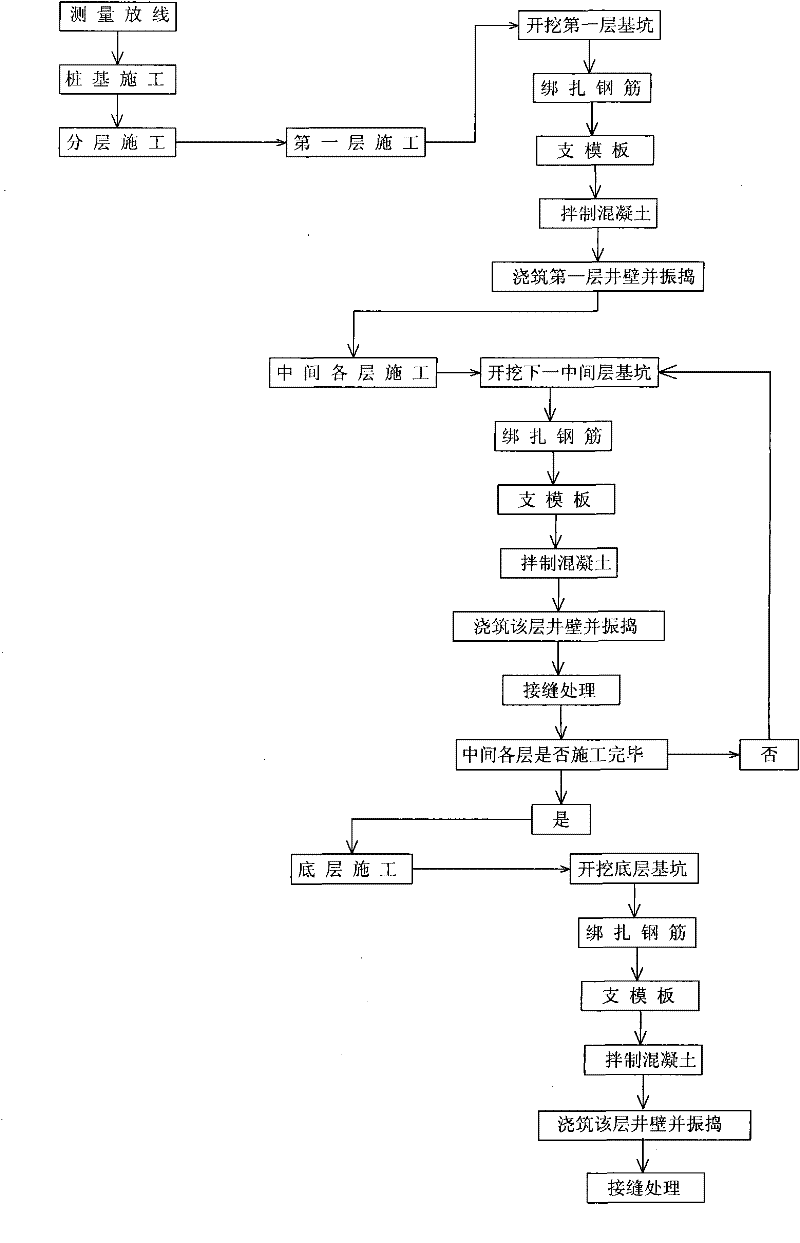

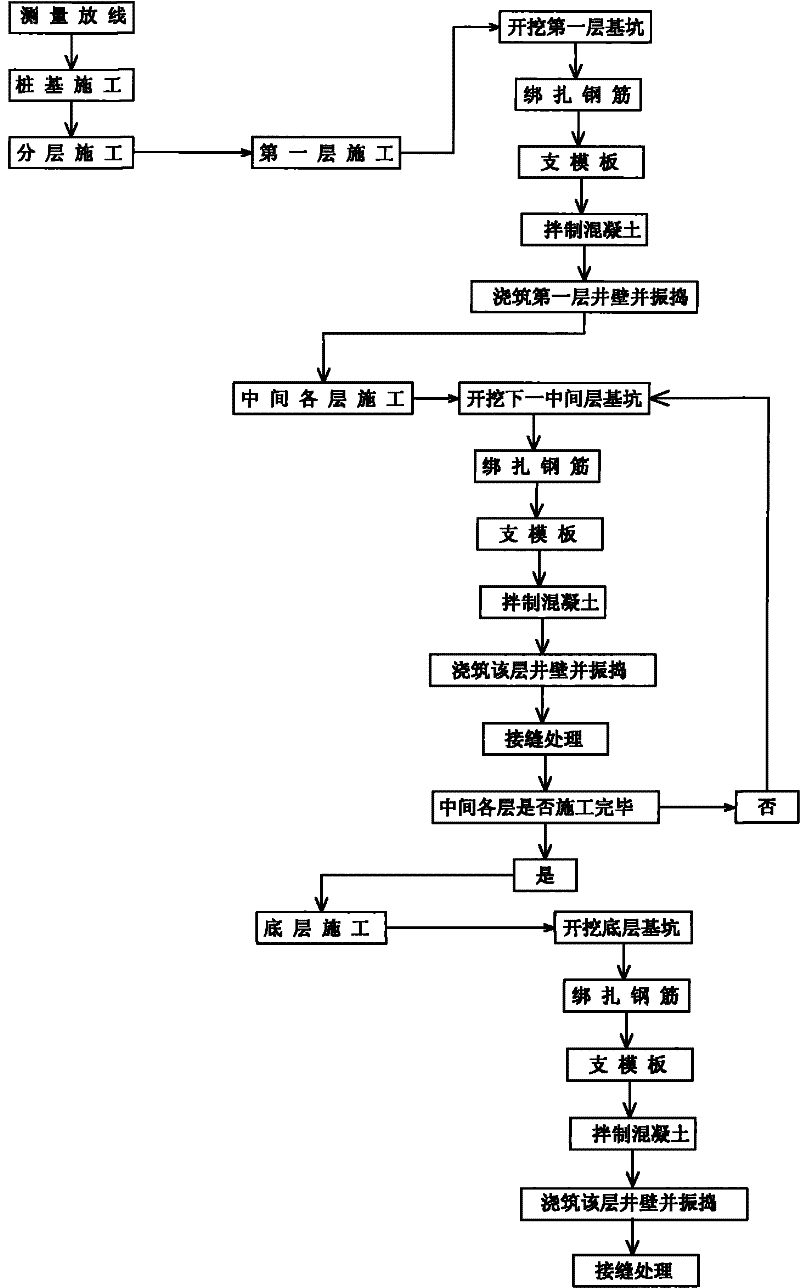

[0022] Such as figure 1 Shown, pipe jacking shaft suspension type construction method of the present invention comprises following construction steps:

[0023] The first is the shaft position measurement and setting out.

[0024] The second is pile foundation construction, at least four engineering piles are vertically pressed into the ground, and the engineering piles are evenly arranged along the periphery of the shaft, and the offset of the engineering piles during construction should be less than the thickness of the well wall. The engineering piles are reinforced concrete cast-in-situ piles or steel pipe piles, and the diameter of the engineering piles is not more than one-third of the wall thickness of the shaft.

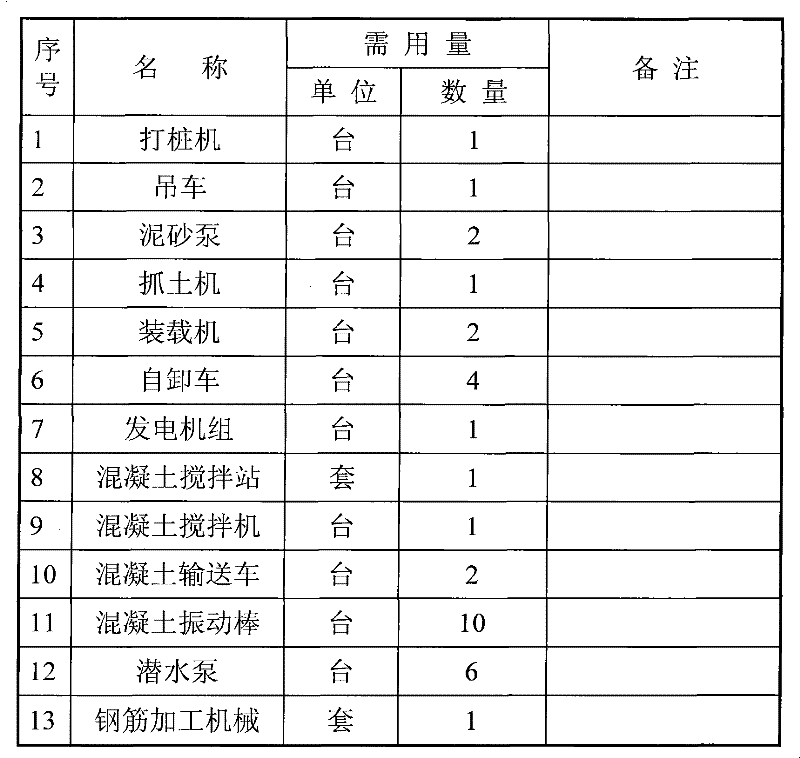

[0025] The third is layered construction, that is, layered excavation of the foundation pit and layered pouring of the shaft wall, wherein the size and position of the foundation pit are the same as the vertical shaft, and this step includes three sub-steps i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com