Vibration and earthquake double-control design method giving priority to vertical industrial vibration isolation

A design method and industrial technology, applied in the field of earthquake and vibration reduction, can solve the problems of limited earthquake isolation capability, vibration change, low redundancy of directional design, etc., achieve good safety and prolong the effect of natural vibration period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The vibration-vibration dual-control design method based on vertical vibration control of the present invention will be further elaborated below in conjunction with the accompanying drawings. The following description is merely exemplary in nature and not intended to limit the invention.

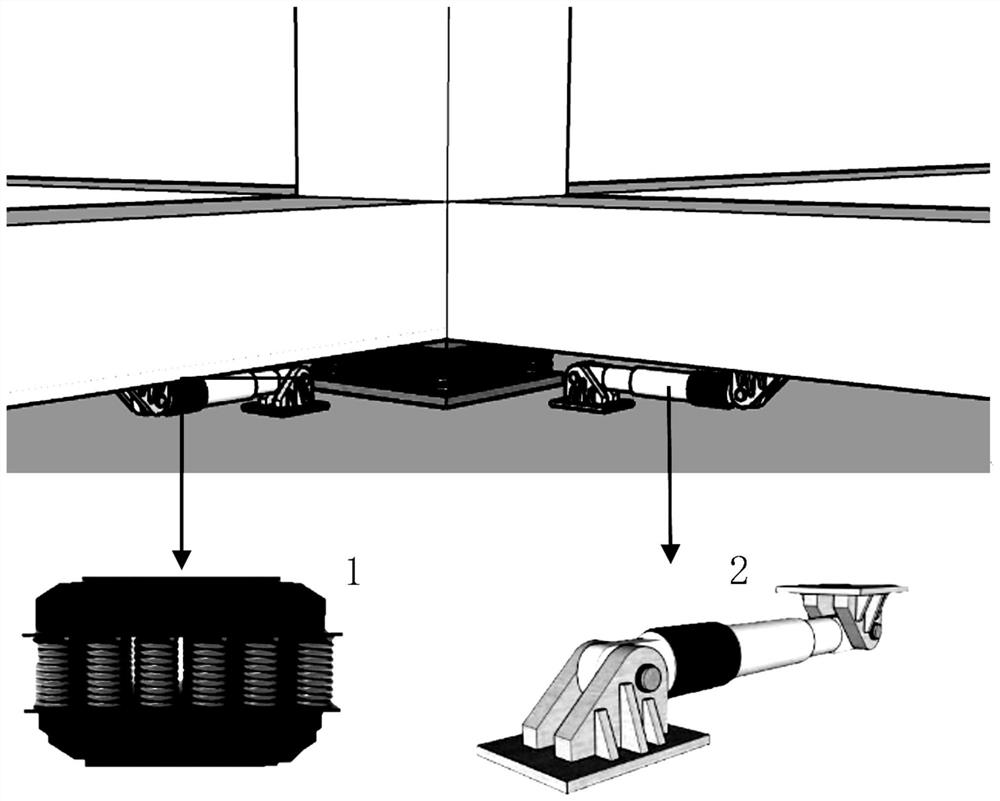

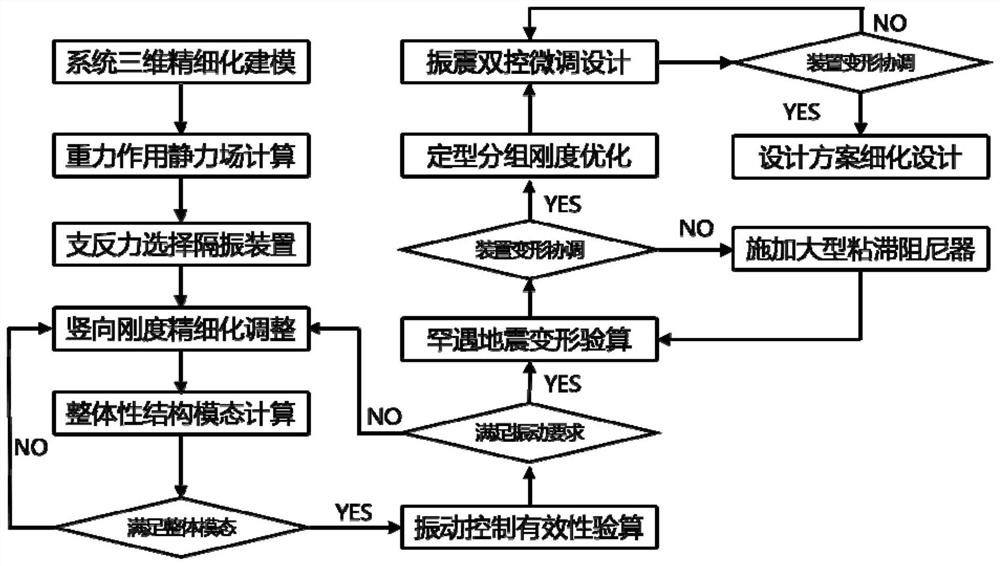

[0027] In view of the defects of the existing technology, this embodiment provides a vibration-vibration dual-control design method that focuses on vertical isolation of industrial vibrations, taking building and equipment use functions and personnel comfort as the leading requirements, and then carrying out safety design. This design mainly focuses on solving engineering vibration hazards, and proposes a vibration-seismic dual-control design method focusing on vertical industrial vibration hazards and supplemented by horizontal earthquake hazards. Vibration design, steel spring vibration isolators are installed under the frame columns to meet the vibration control requirements; secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com