Integrated circuit punching and cutting forming machine material-receiving system automatic discharging tube machine

An integrated circuit and automatic discharge technology, applied in the direction of circuits, conveyors, electrical components, etc., can solve the problems of low discharge accuracy, restricting production efficiency, and high labor intensity, so as to improve production efficiency, liberate manual labor, and save energy. The effect of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

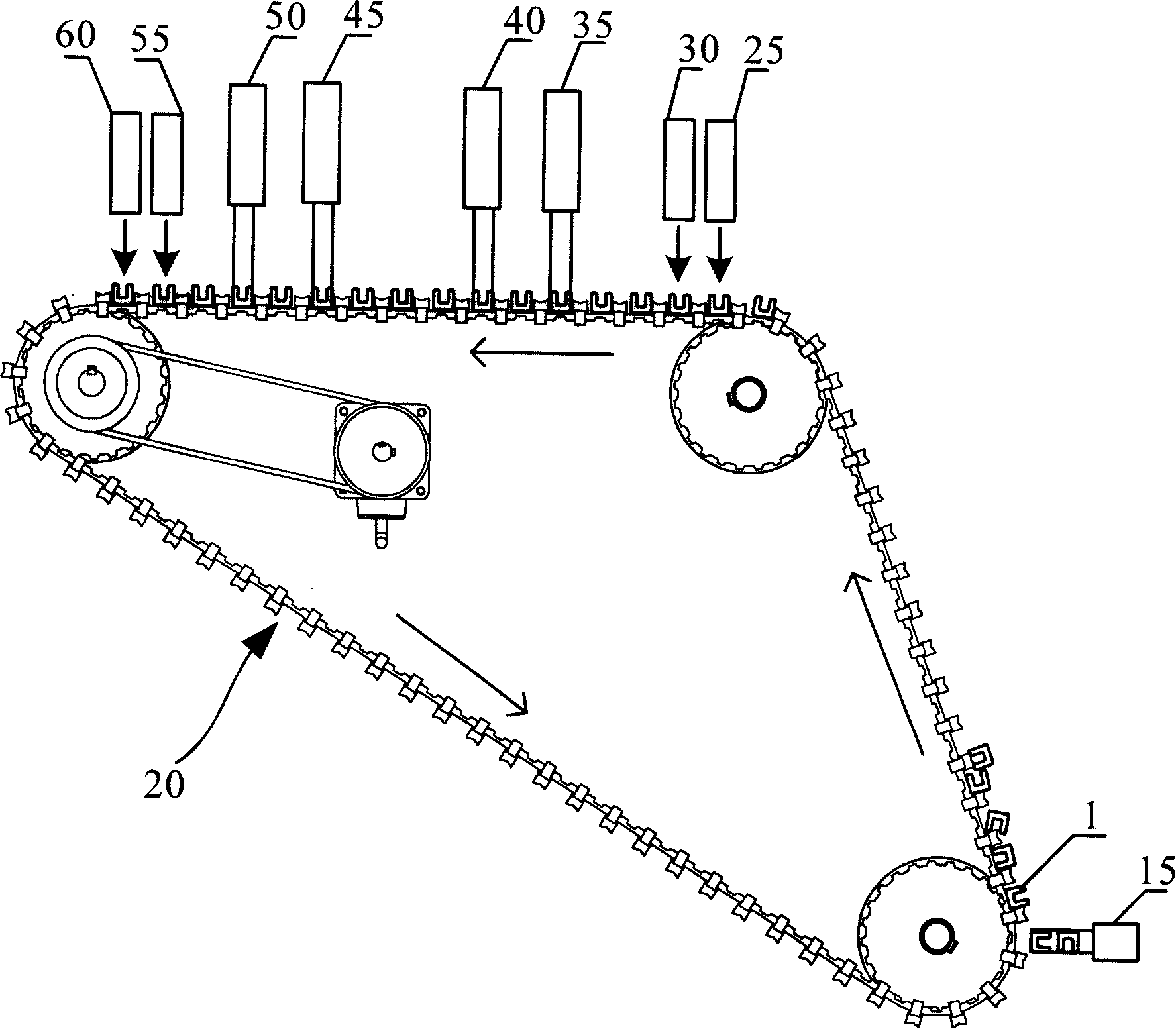

[0019] In the back-stage packaging and testing process of integrated circuit manufacturing, the integrated circuit is transferred to the discharge nozzle through the material channel. The invention uses an automatic pipe arrangement machine to automatically and neatly arrange the collection pipes, and then sends them to the bottom of the discharge nozzle for punching. The formed integrated circuits are sequentially loaded into the receiving tube.

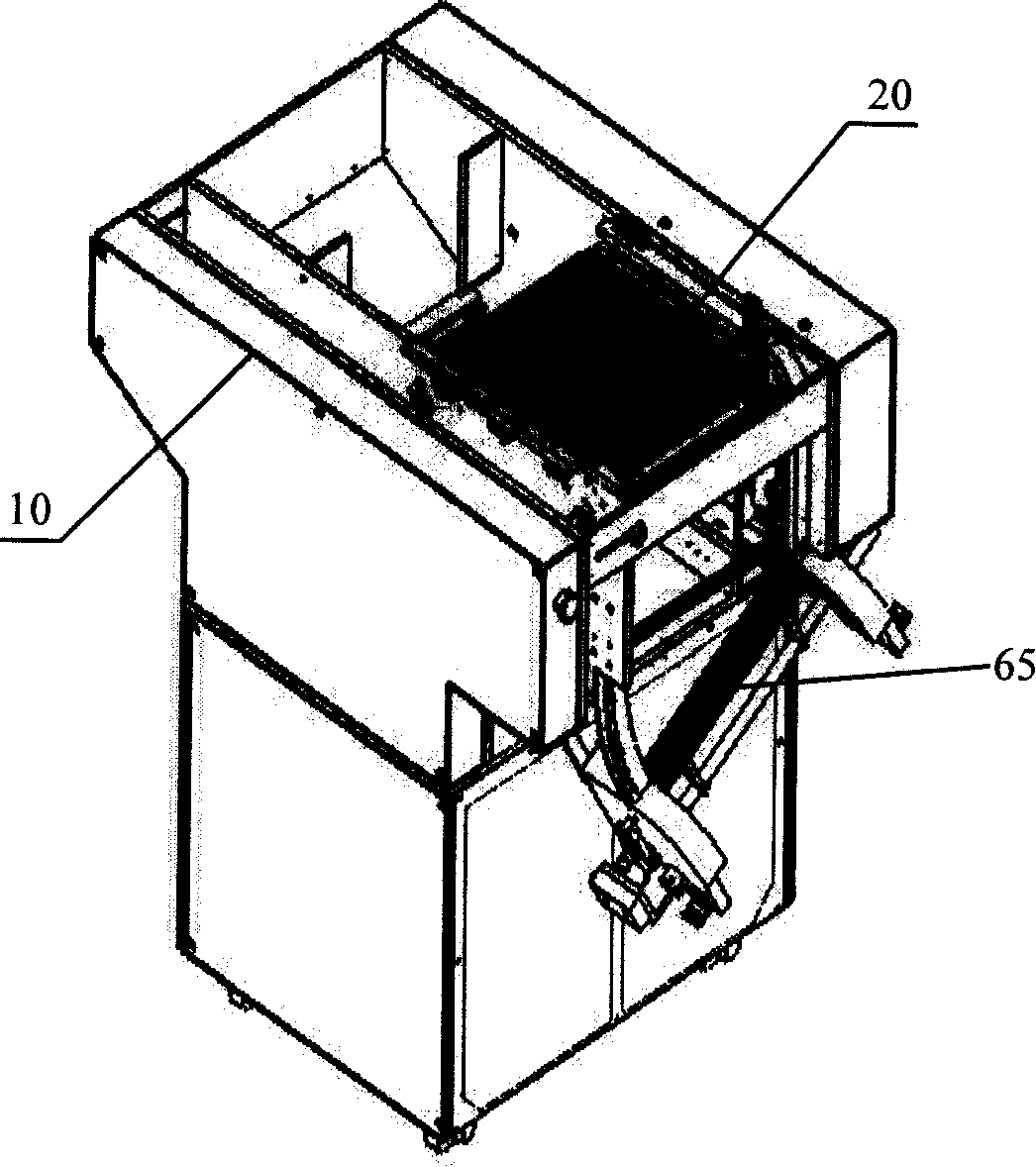

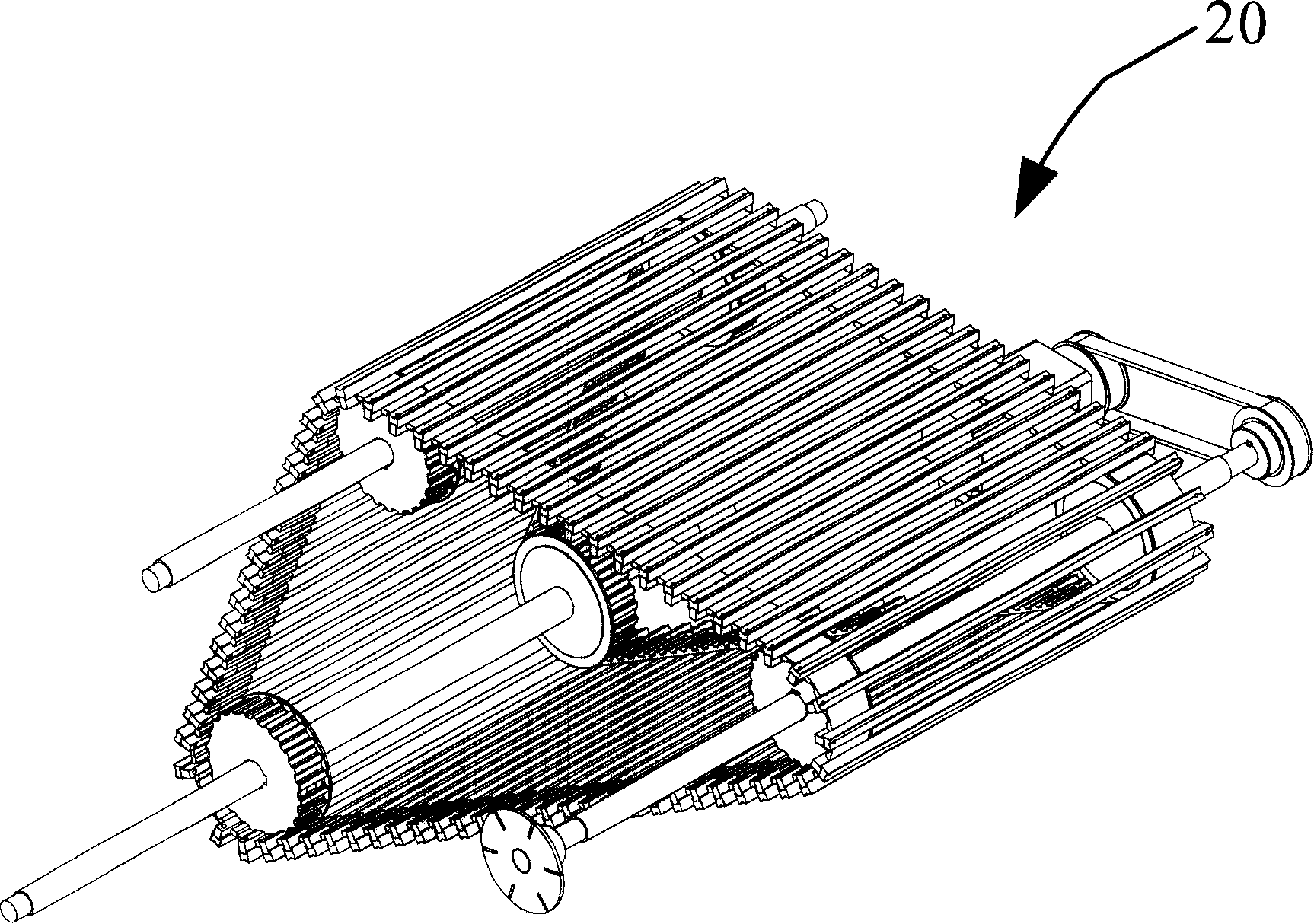

[0020] Such as Figure 1~3 As shown, the integrated circuit punching and forming machine receiving system automatic discharge pipe machine includes a frame 10, a feeding mechanism 15, a feeding and conveying device 20, a first direction detector 25, a second direction detector 30, The first set of 90° rotating mechanism 35, the second set of 90° rotating mechanism 40, the first set of 180° rotating mechanism 45, the second set of 180° rotating mechanism 50, the first direction confirming instrument 55, the second direction confirmin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com