Vertical daily garbage incinerator

A domestic waste incineration and vertical technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems that the control of the gasification and incineration process cannot be realized, the gasification process requires high real-time performance, and it is difficult to stabilize for a long time. Increased section, easy maintenance and cleaning, and reduced labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

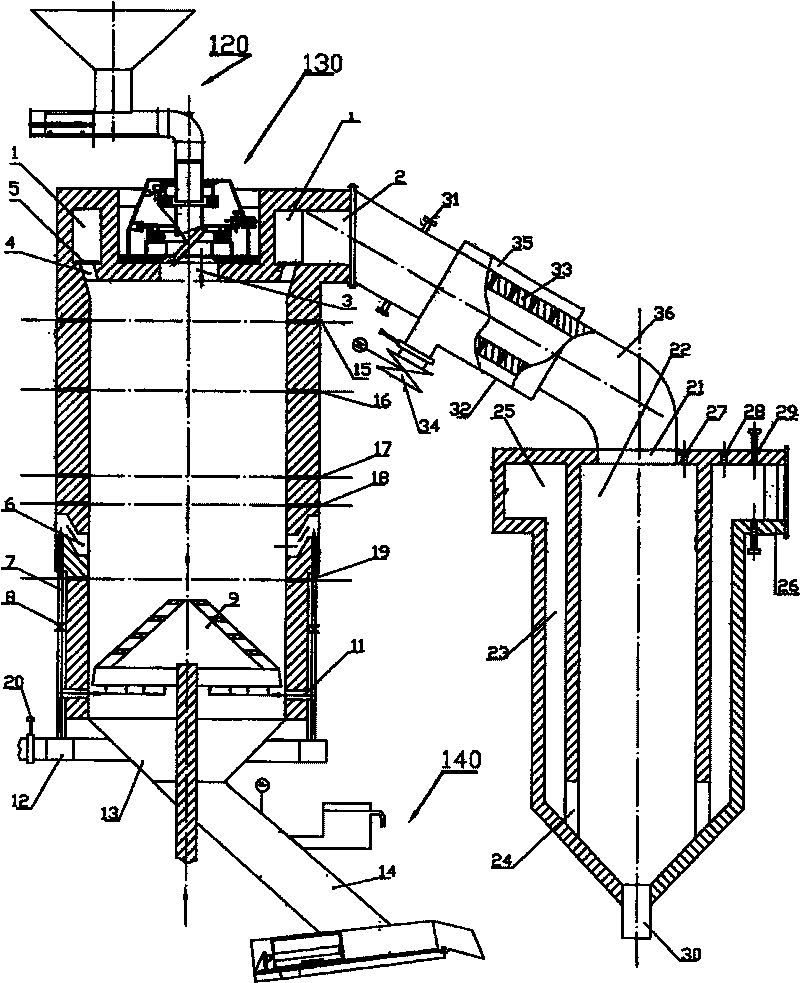

[0052] Such as figure 1 , figure 2 and image 3 As shown, the vertical domestic waste incinerator of the present invention includes a primary combustion furnace operating in gasification conditions and a secondary combustion furnace operating in gas combustion conditions. The tops of the primary and secondary combustion furnaces are connected to smoke Tube.

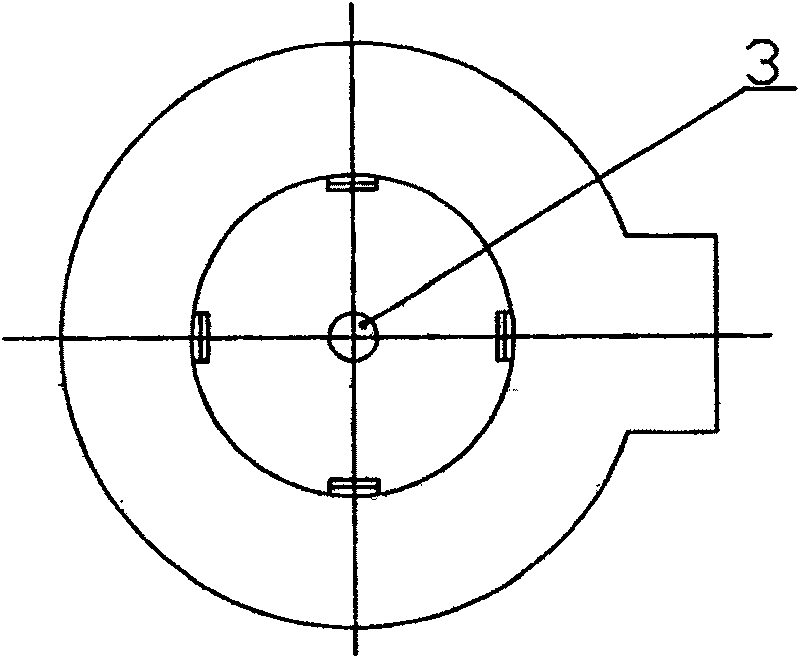

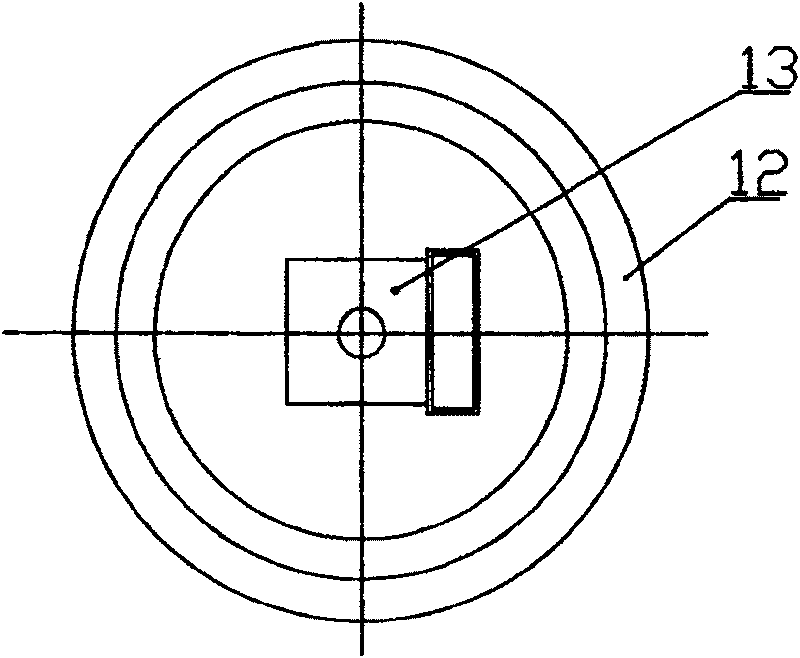

[0053] The primary combustion furnace includes a cylindrical furnace body with a top wall, a hydraulic pusher, a hydraulic distributor, a hydraulic slag discharger, a tower grate slag discharger 9 installed at the bottom end of the cylindrical furnace body, and an air distribution device. . The hollow part in the furnace body is the furnace chamber. The central position of the furnace top wall of the primary combustion furnace is provided with a feeding port 3, and the top e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com