Light irradiation device and inkjet printer

A light irradiation and reflector technology, applied in refractors, reflectors, printing devices, etc., can solve the problems of increasing the overall weight, size, and cost of inkjet printers, achieve high peak illuminance, reduce the degree of thermal influence, Prevent deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Hereinafter, the light irradiator and the head of the inkjet printer according to the embodiment of the present invention will be described.

[0094] (1) Light irradiator

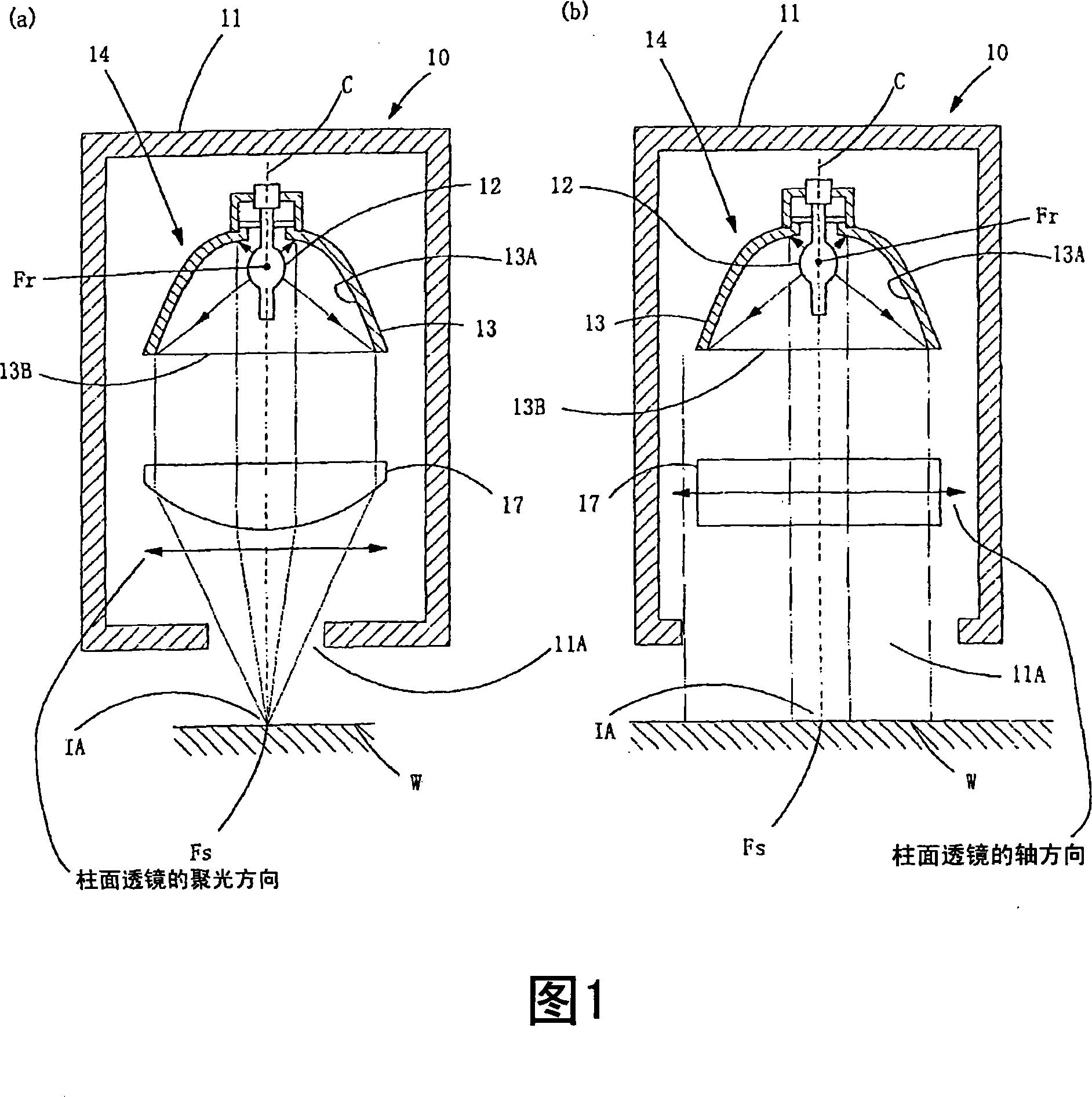

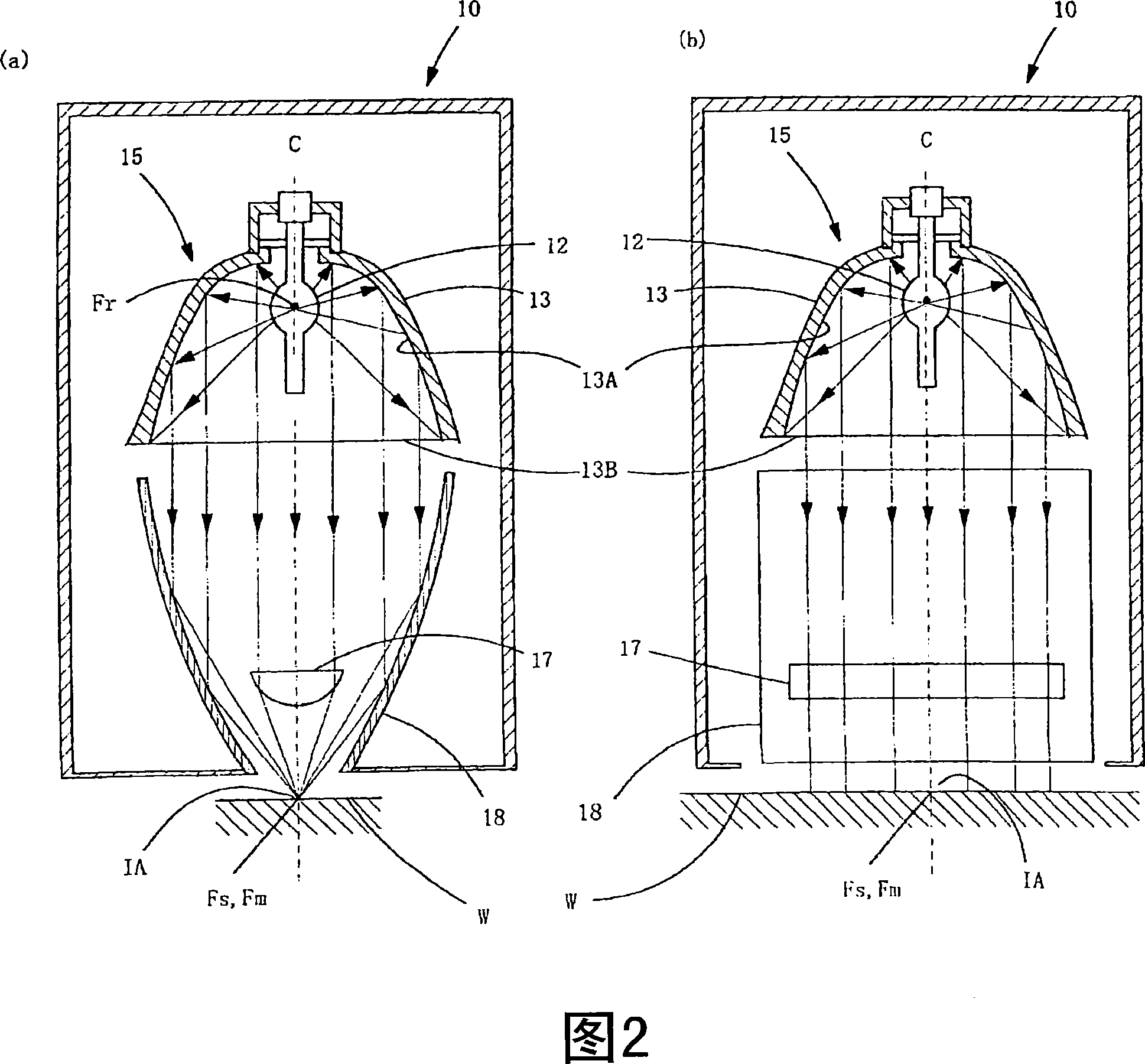

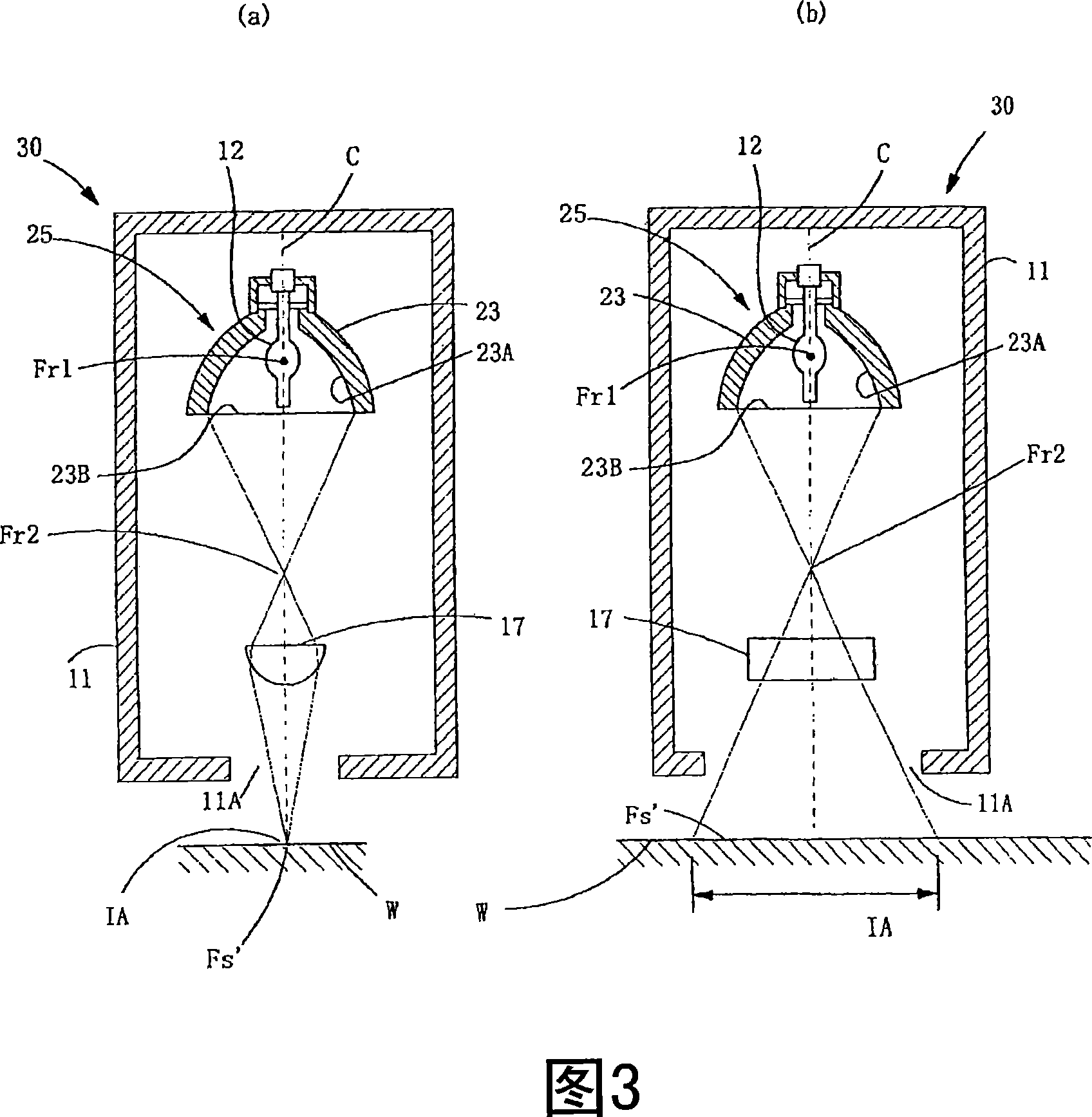

[0095] The basic structure of the light irradiator of the present invention is provided with: at least one light source unit composed of a short arc discharge lamp and a reflector that reflects light from the discharge lamp, and light irradiated from the light source unit is incident and condensed and emitted It is composed of a cylindrical lens in the uniaxial direction, and condenses and irradiates light from the discharge lamp as a light irradiation area extending linearly on the light irradiation surface.

[0096] Fig. 1 is a cross-sectional view showing the basic structure of the light irradiator of the present invention, Fig. 1(a) is a cross-sectional view viewed from the axial direction of a cylindrical lens, and Fig. 1(b) is a view showing the condensing light from the cylindrical lens Section vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com