Wind turbine impeller installed with blown flap wing-like vane

A technology of airfoil blades and wind turbines, applied in the field of wind turbine impellers, can solve the problems of hindering the flow of airflow on the pressure surface, consuming energy, and difficult to control, etc., and achieve the effects of increasing the utilization coefficient of wind energy, reducing the cost of power generation, and facilitating implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

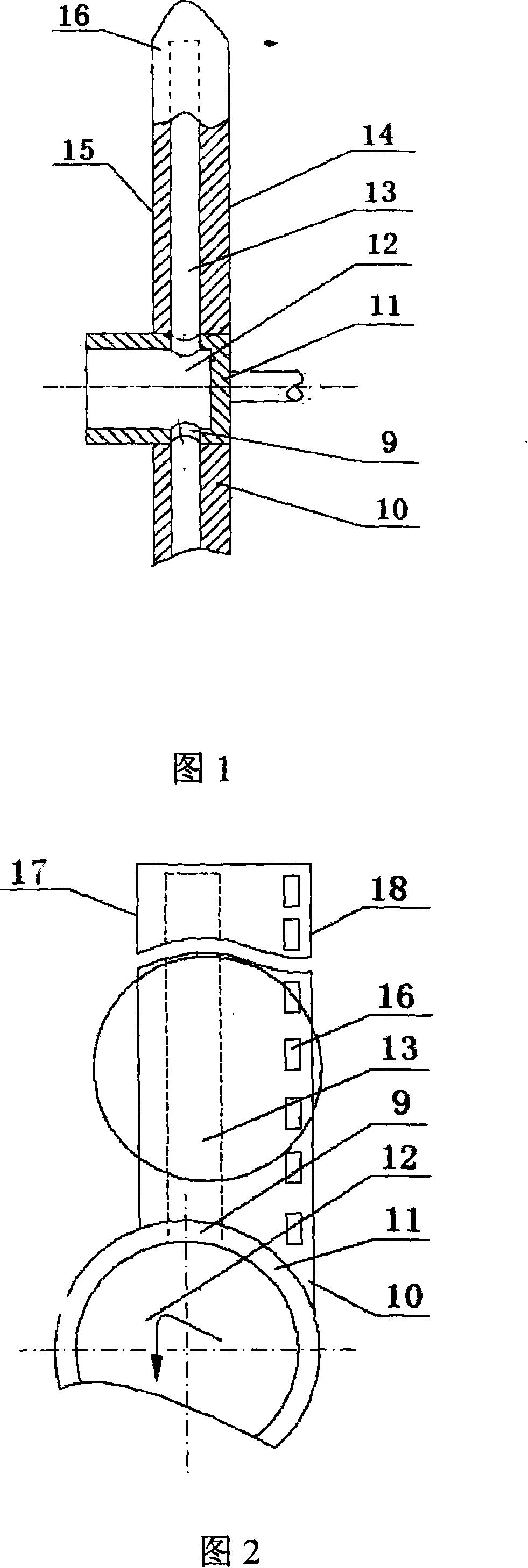

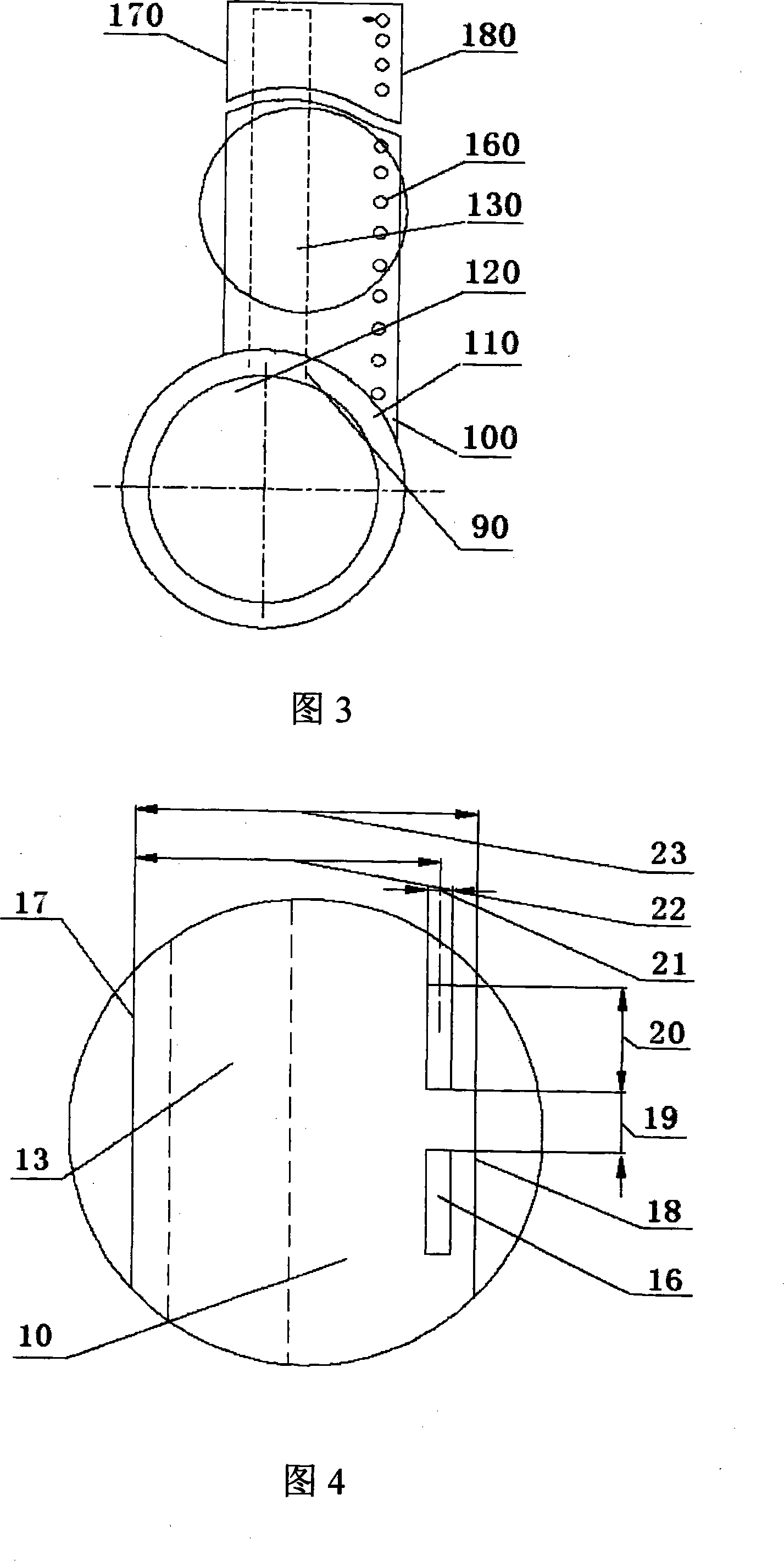

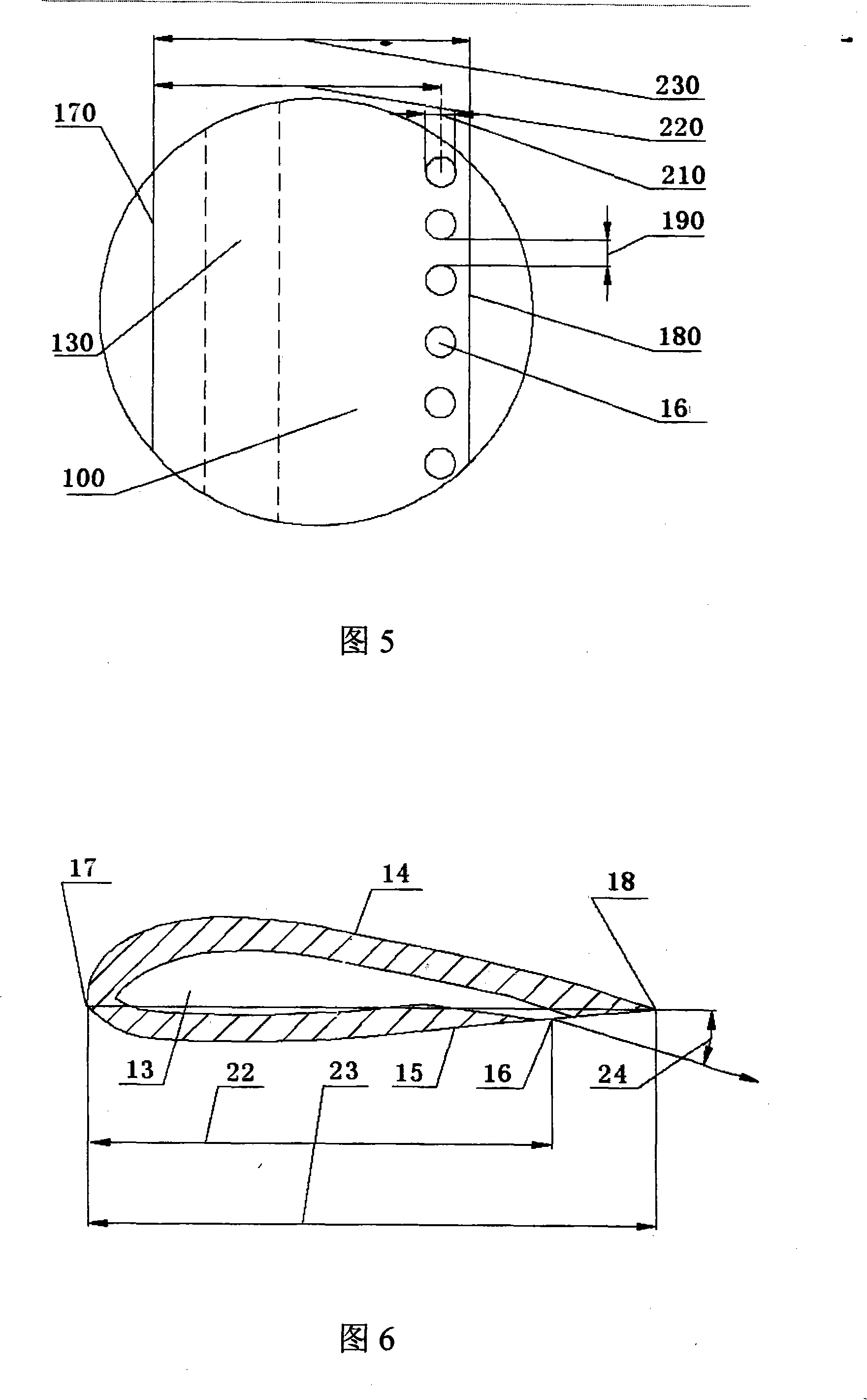

[0018] With reference to Fig. 1 and 9, wind turbine wind wheel among the present invention is made up of blade 10 and hub 11, and wherein blade 10 and hub 11 are all hollow, and blade 10 has suction surface 14 and pressure surface 1, the trailing edge of pressure surface 15 There is a row of fumaroles 16 nearby. When the wind turbine is working, the front wind 1 enters through the hole 12 on the hub, and enters the hole 13 in the blade through the hole 9 on the peripheral wall of the hub, and then sprays out from the jet hole 16 on the pressure surface. The jet holes can only be distributed in the blade tip region, or the middle part of the blade, or the root region on the blade pressure surface 15, or can be distributed in any two regions of the blade tip, middle part or root; they can also be distributed in the whole blade On the pressure surface 15, from the blade root to the blade tip.

[0019] With reference to Fig. 2, this is an embodiment of the present invention, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com