Radial meter with hydraulic drive rotary device

A slewing device and radial measurement technology, which are applied in mechanical diameter measurement, control of workpiece feed motion, and machine tools designed for grinding workpiece rotating surfaces. Inconvenience and other problems, to achieve the effect of considerable economic benefits, large driving force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

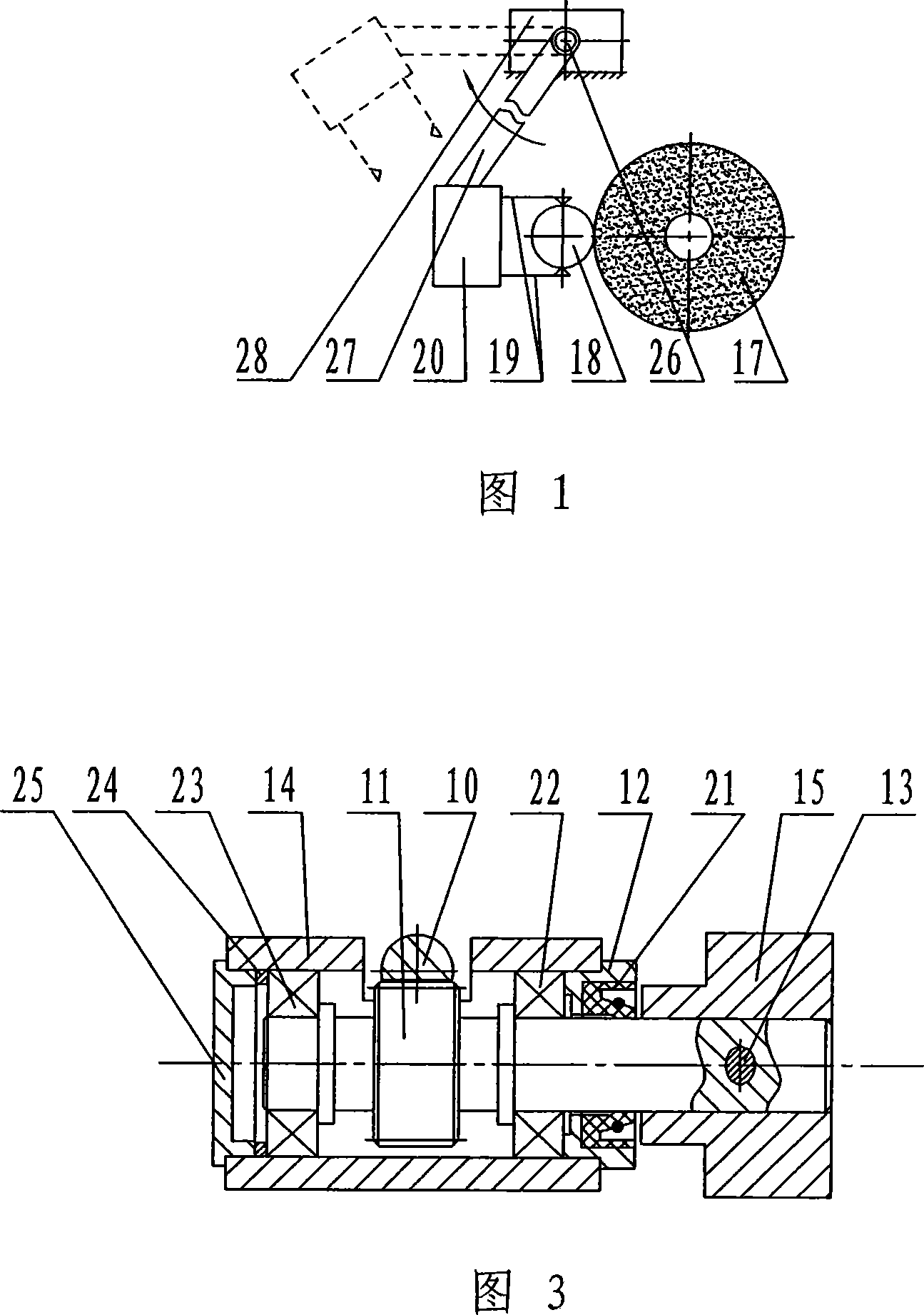

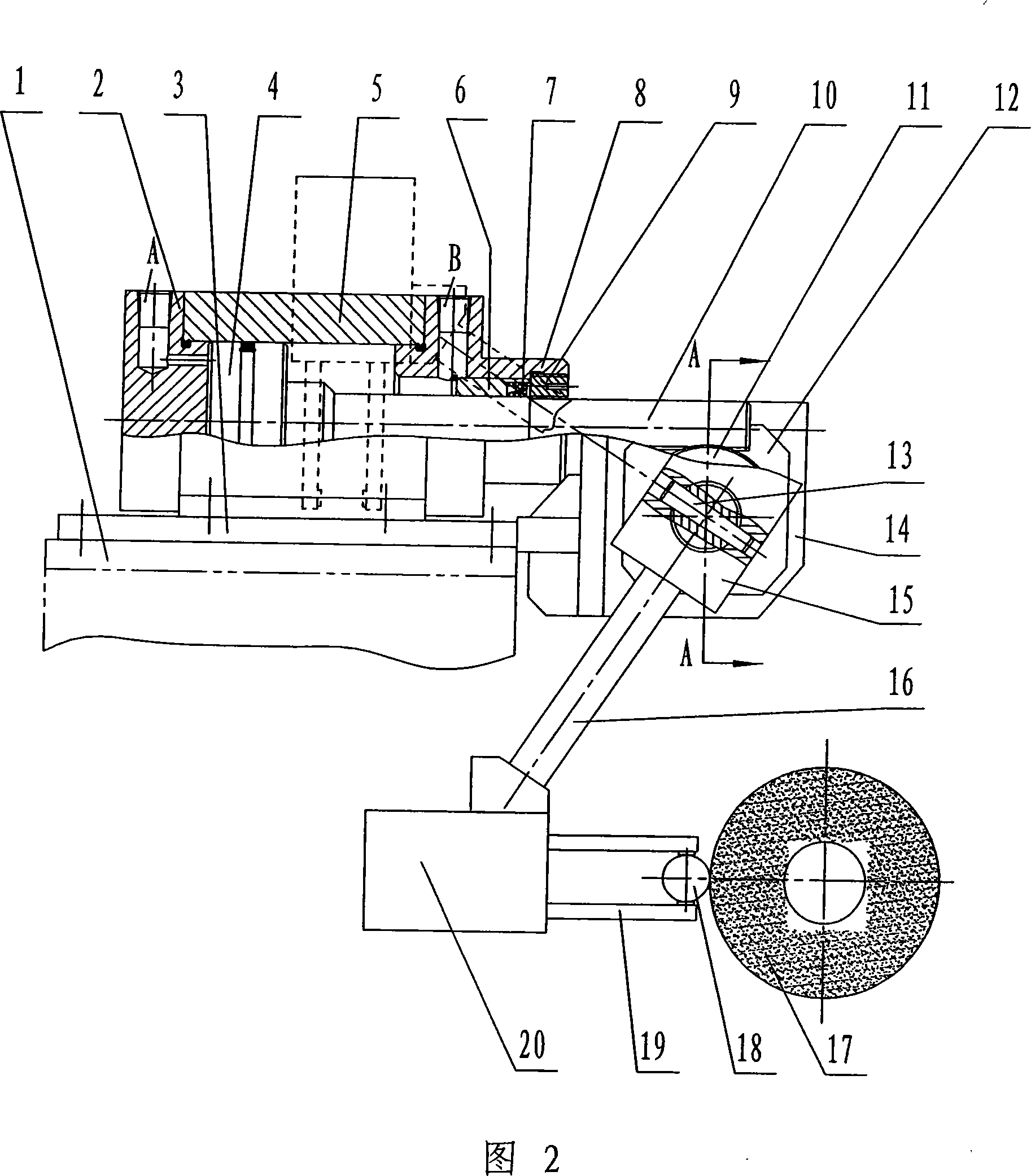

[0015] It can be seen from Fig. 2 and Fig. 3 that the radial measuring instrument with a hydraulically driven rotary device of the present invention includes a mounting base 3 and a radial measuring instrument body 20 with telescopic claws 19, wherein a hydraulic cylinder body is installed on the upper part of the base 3 5. The two ends of the hydraulic cylinder 5 are respectively provided with sealed left and right end covers 2 and 8, and the piston rod 10 with a rack of the piston 4 fitted with the hydraulic cylinder 5 passes through the guide sleeve 6 and the screw sleeve in turn. 9 extends outward, the guide sleeve 6 and the screw sleeve 9 are fixedly connected with the right end cover 8 respectively, the piston rod 10 is slidably fitted with the guide sleeve 6, and a seal 7 is also provided between the guide sleeve 6 and the screw sleeve 9; , The right end covers 2 and 8 are respectively provided with oil ports A and B which communicate with the inner cavity of the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com