Jointed rock permeability detection method

A detection method and water permeability technology, applied in soil material testing, material inspection products, instruments, etc., can solve problems such as unreasonable, difficult, and widening the gap between the experiment and the actual situation, and achieve a large adjustable range and high detection accuracy , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

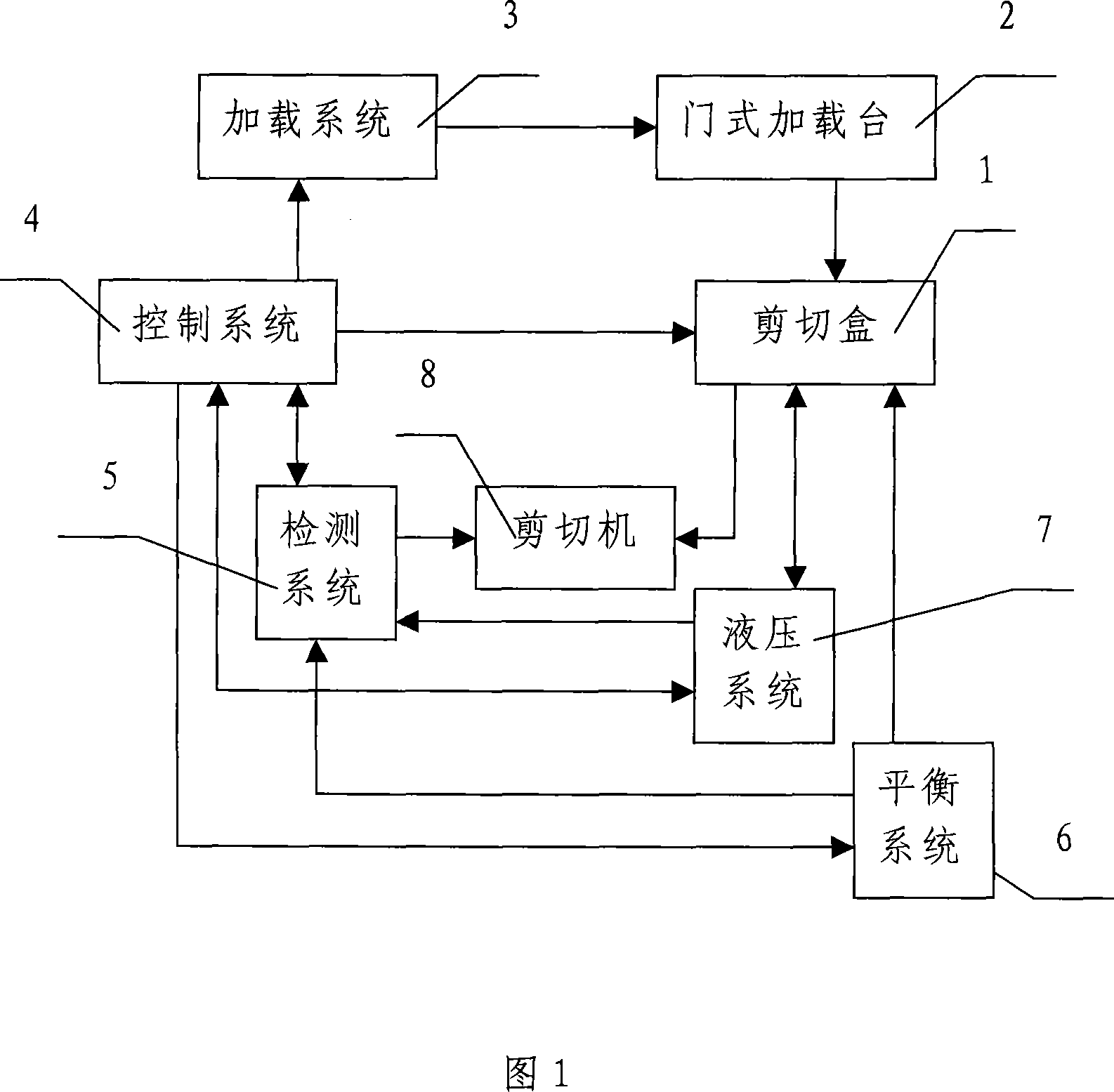

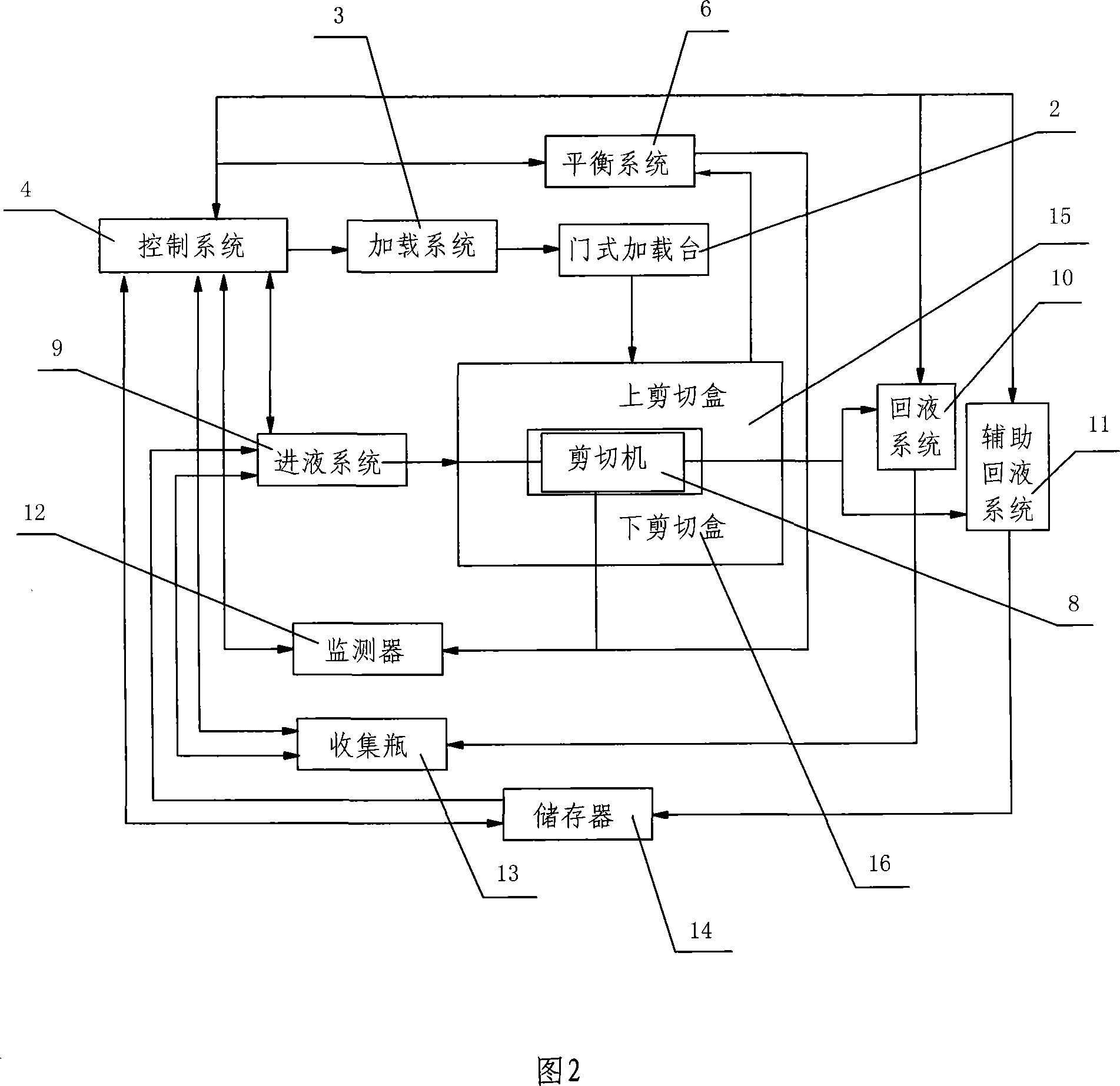

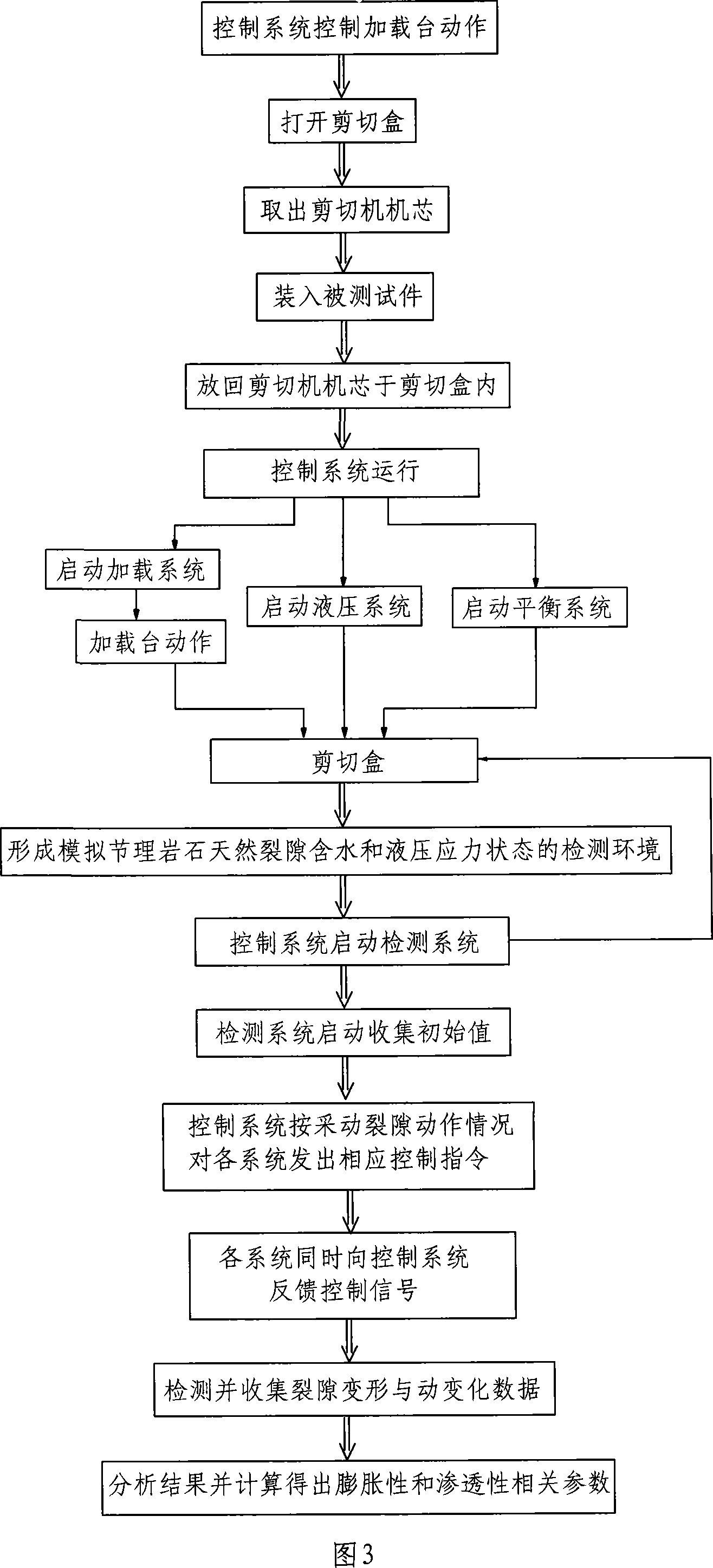

[0030] 1 and 2, the jointed rock water permeability detection device includes a shear box 1 composed of an upper shear box 15 and a lower shear box 16, a control system 4, controlled by the control system 4 and controlled by a loading platform. The cutting box 1 applies the loading system 3 of normal stress and shear stress, the shearing machine 8 placed in the inner cavity of the shearing box 1 , and the detection system 5 controlled by the control system 4 , the balance system 6 and the hydraulic system 7 . The control system 4 controls the loading system 3 to apply normal stress and shear stress to the specimen, and controls the hydraulic system 7 to provide the specimen with the hydraulic environment required for testing. The loading system 3 applies normal stress and shear stress to the shearing box 1 through the loading table, and the shearing machine 8 is placed in the cavity formed between the upper shearing box 15 and the lower shearing box 16, and the shearing machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com