A thyristor trigger method

A thyristor and high-voltage thyristor valve technology, applied in electrical components, pulse technology, electronic switches, etc., can solve problems such as difficulty in realization and difficulty in obtaining energy, and achieve the effect of reducing output energy, being easy to realize, and requiring low triggering power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

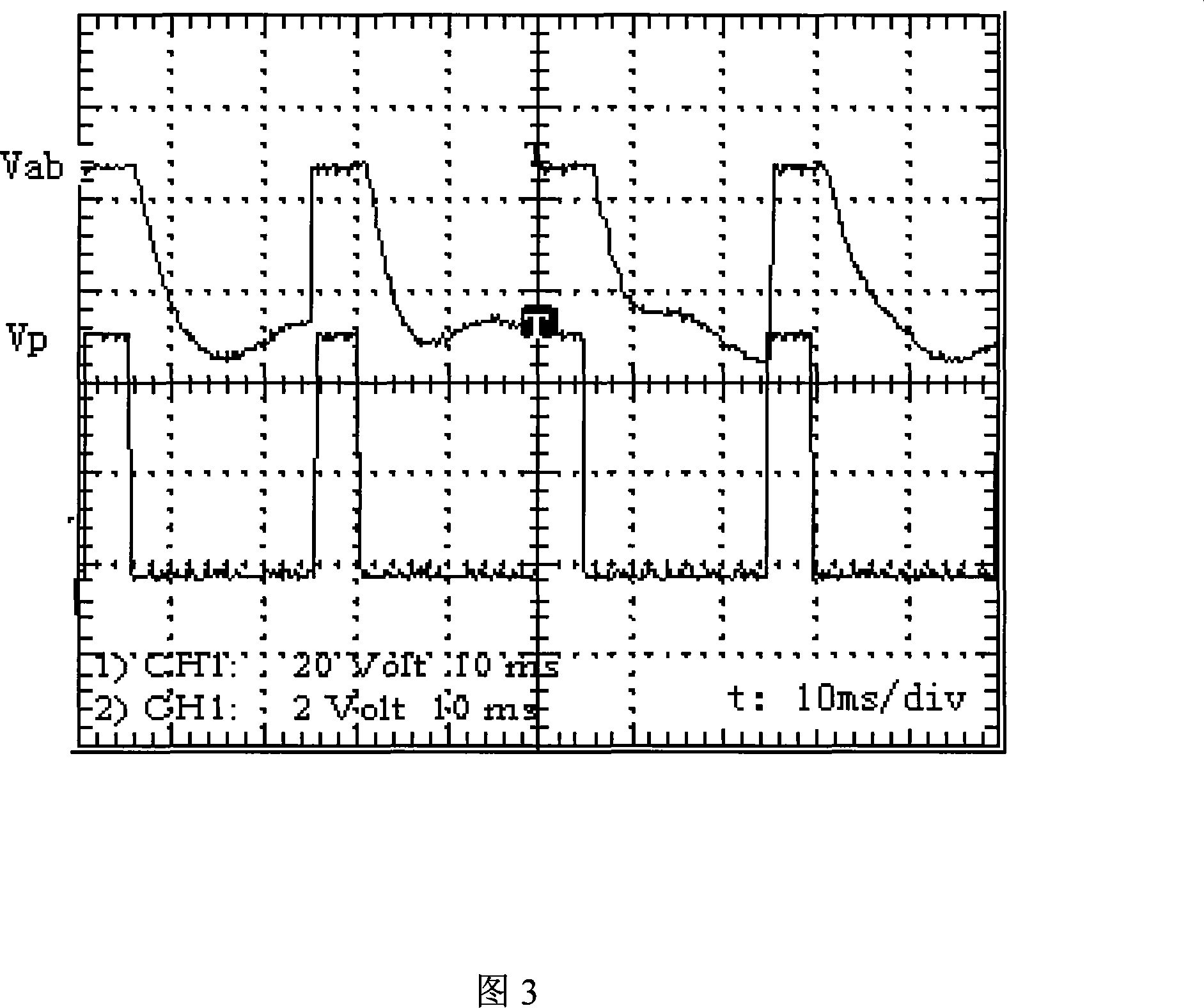

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

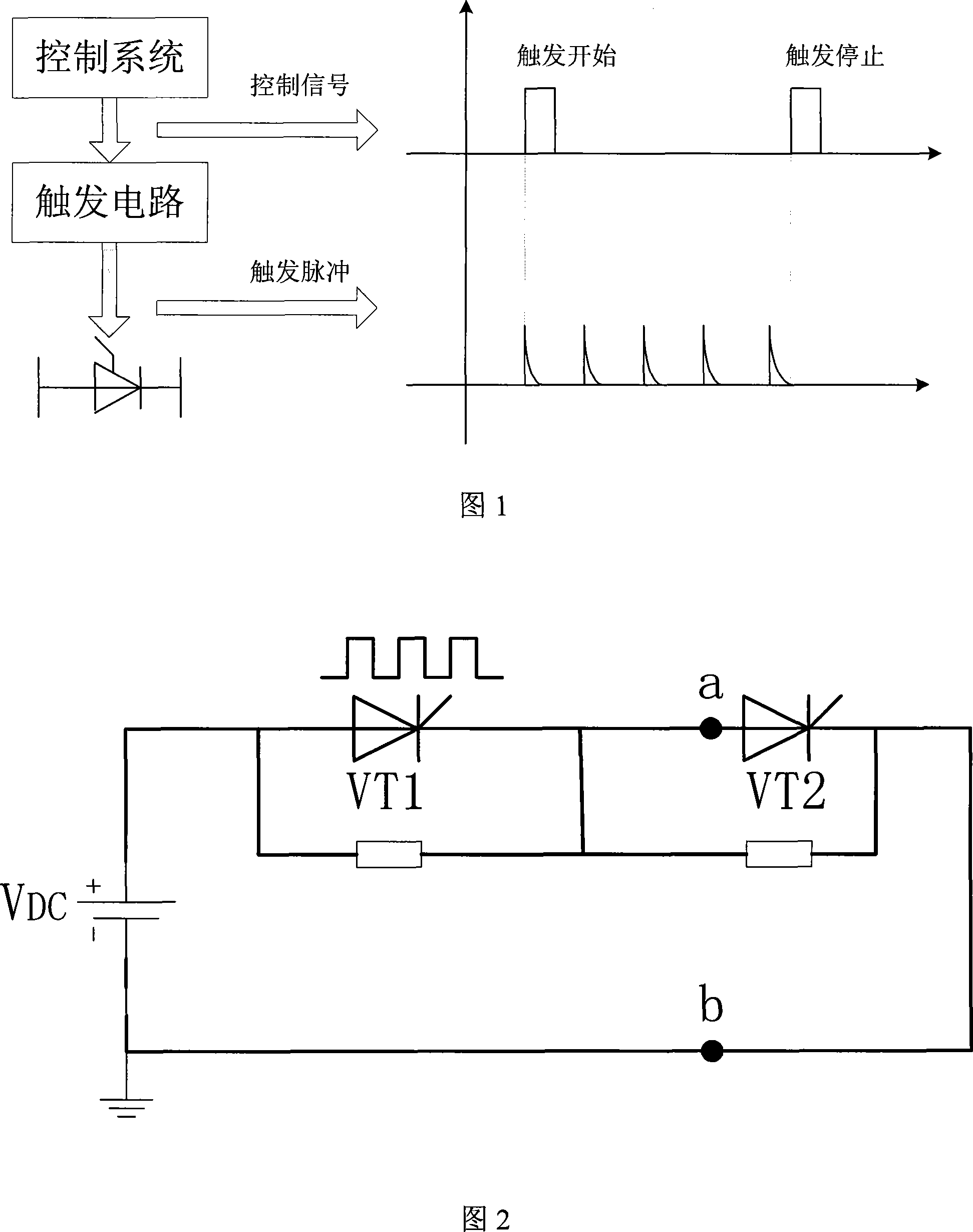

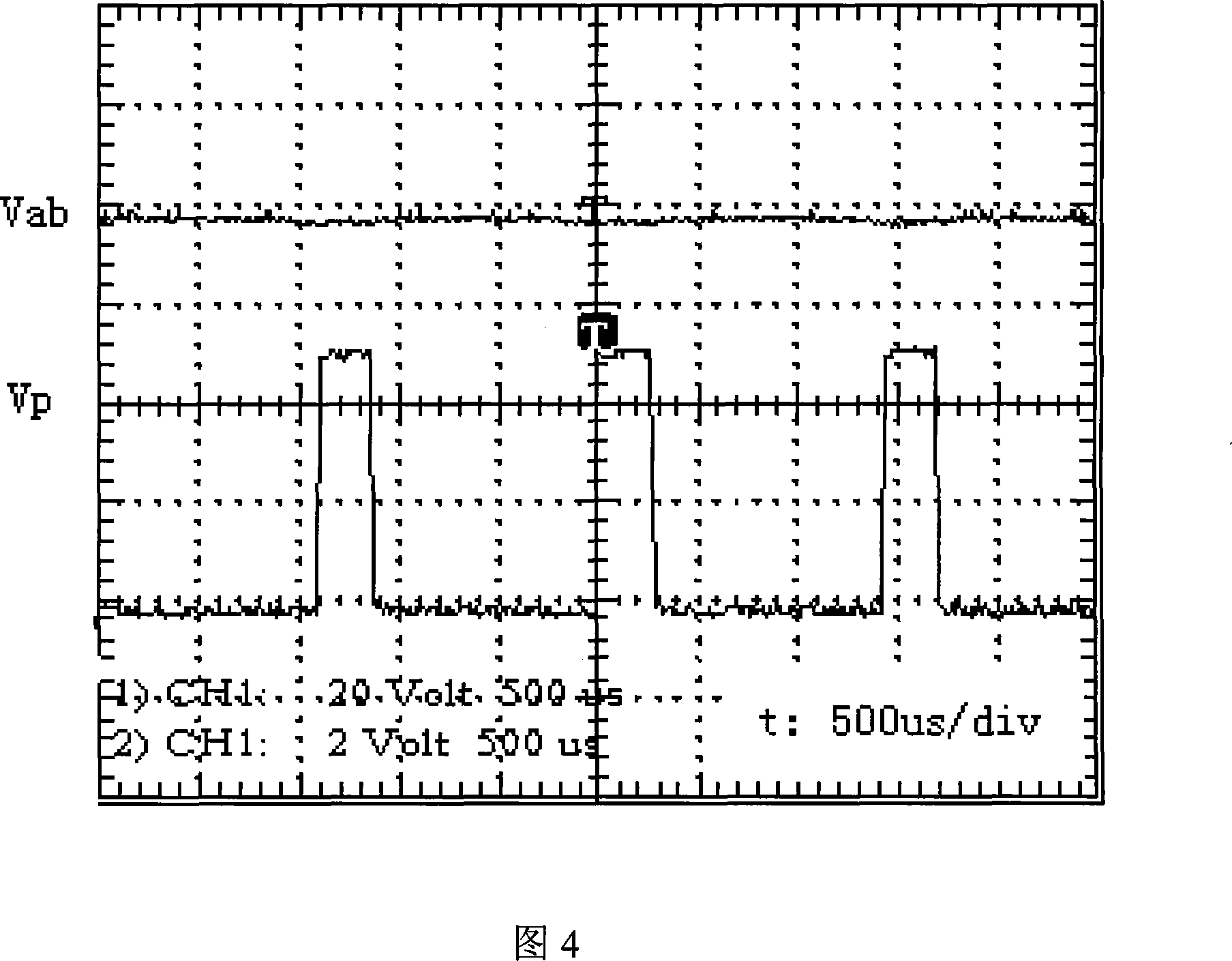

[0011] The schematic diagram of the trigger scheme is shown in Figure 1. When there is no current path or the current path cannot be realized continuously and the thyristor valve needs to be kept in a low-resistance state, the control system sends a trigger start signal, and the trigger circuit immediately sends out a high-frequency signal after receiving the trigger start signal. The pulse train is added to the gate of each thyristor valve to meet the control requirements. Each pulse signal of the high-frequency pulse train meets the basic triggering requirements of the thyristor, and the frequency of the high-frequency pulse train should be greater than 500 Hz.

[0012] Each pulse leading edge satisfies the condition of strong triggering of a general thyristor, which can promote the redistribution of the carrier concentration inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com