System and method for recycling mother solution of purify terephthalic acid and catalyst purifying regeneration

A technology for the recovery of purified terephthalic acid and mother liquor, used in chemical instruments and methods, separation/purification of carboxylic acid compounds, chemical recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

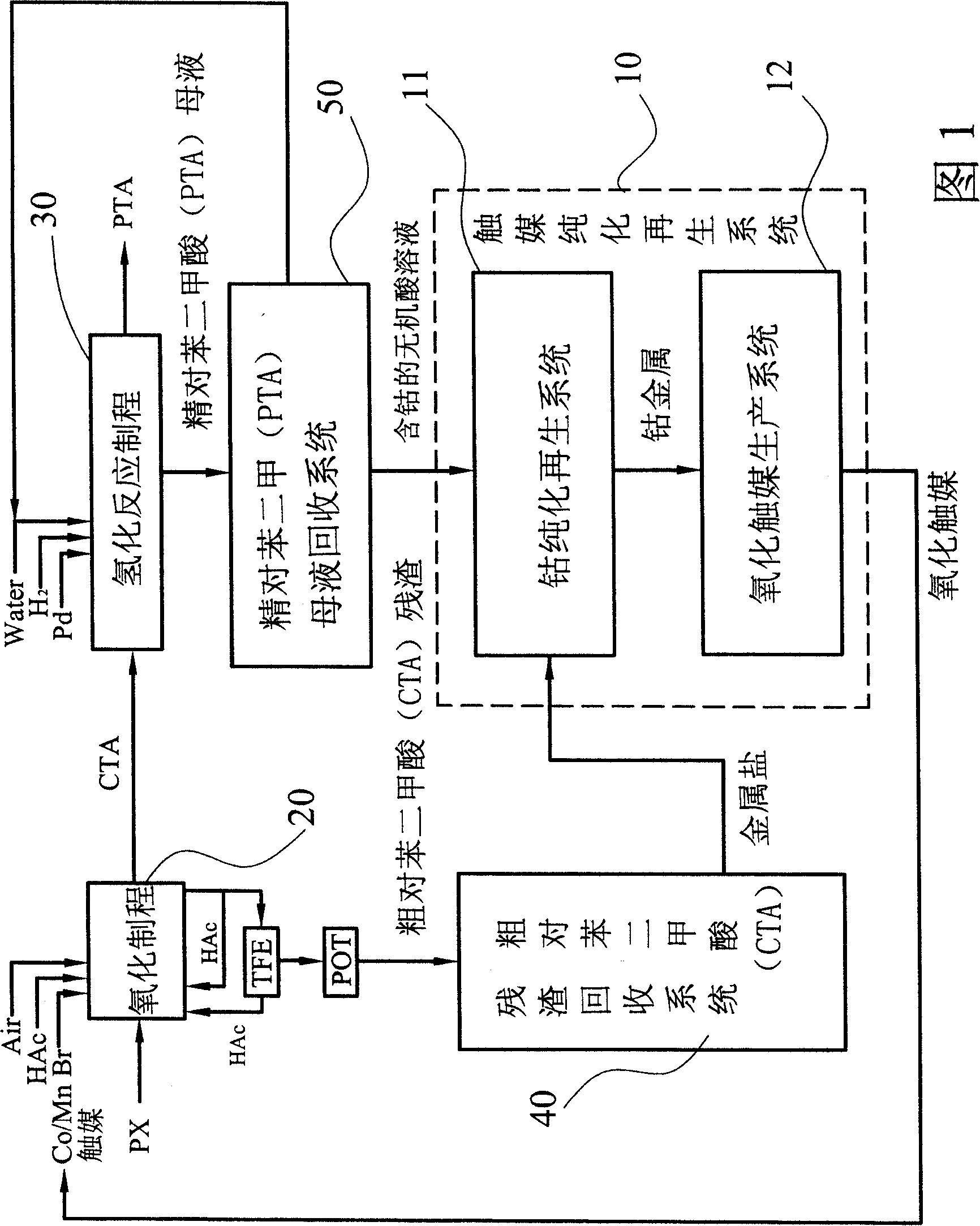

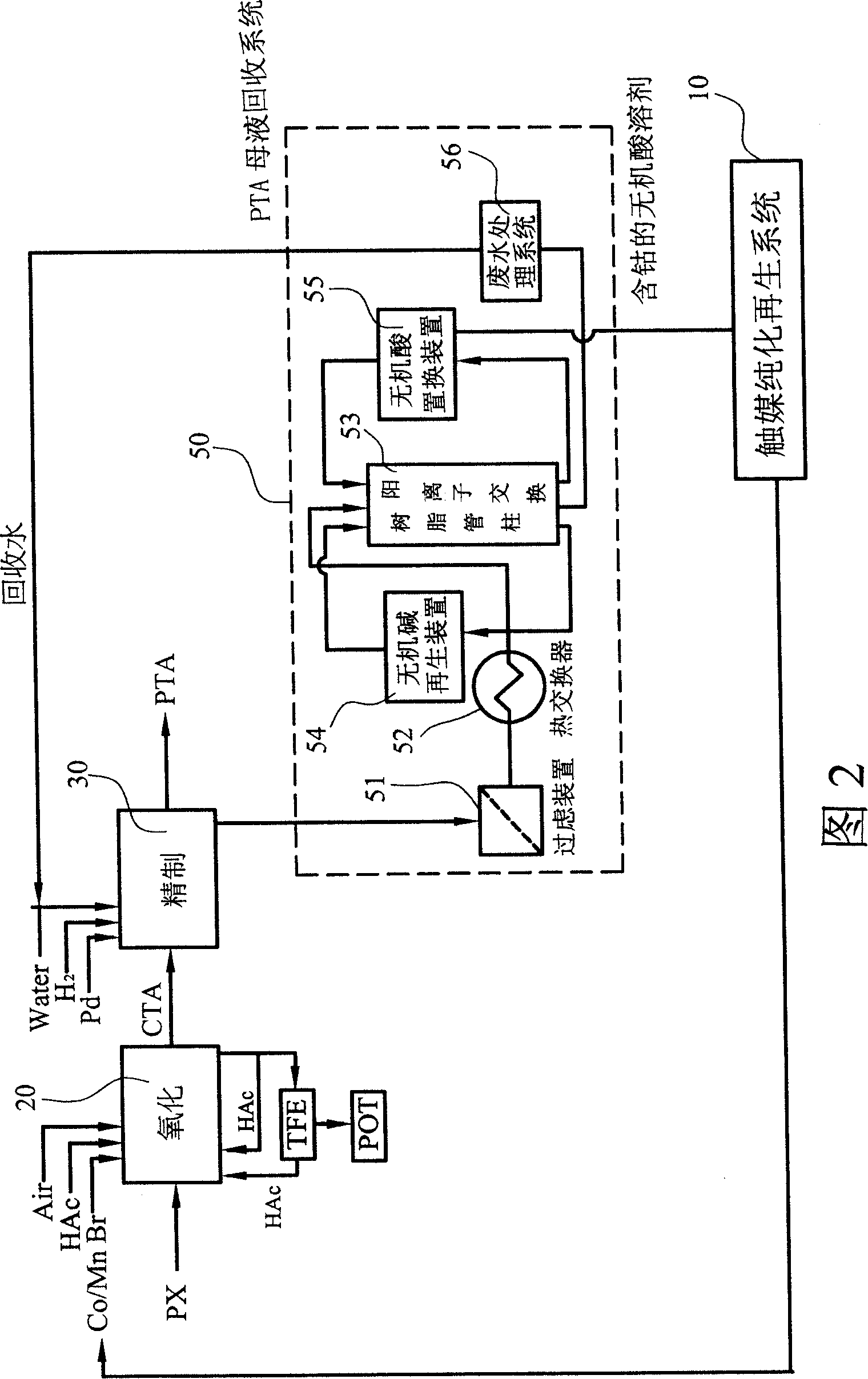

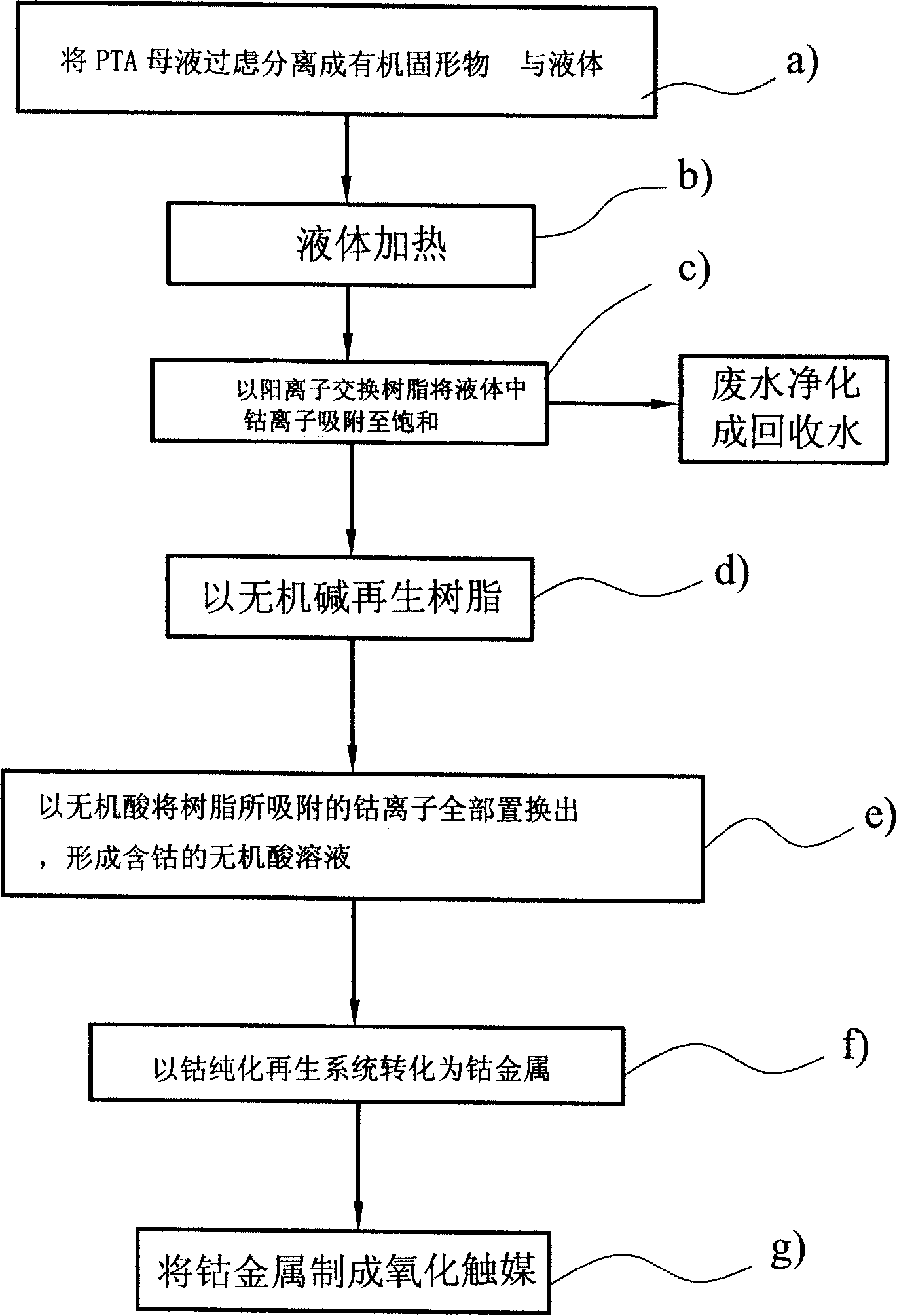

[0035] Please refer to Fig. 1, the production method of Purify Terephthalic Acid (PTA) is to use p-xylene (PX) as raw material, after oxidation reaction process 20 and hydrogenation (purification) reaction process 30, the purity is 99.95% The above purified terephthalic acid (PTA) white powder.

[0036] In the oxidation reaction process 20, an oxidation catalyst containing cobalt, manganese, and bromide ions needs to be added, and divalent cobalt and manganese ions are used as catalysts, and bromide ions are used as starters; at the same time, the main reaction is to blow air (Air) into the oxidation process. In the reactor, mix with p-xylene, catalyzer, acetic acid (HAc), and the mixed solution is at 16.5kg / cm 2 G pressure and 204 ° C oxidation reaction to produce crude terephthalic acid (CTA).

[0037] The crude terephthalic acid (CTA) residue is recovered through a crude terephthalic acid (CTA) residue system 40 and made into metal salts.

[0038] In the hydrogenation rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com