A kind of relief powder for exterior wall and preparation method thereof

A technology for embossing and exterior walls, applied in the field of coatings, can solve the problems of uneven quality of polymers, high surface pH, low bonding strength, etc., to achieve cost-effective, high bonding strength, waterproof and breathable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

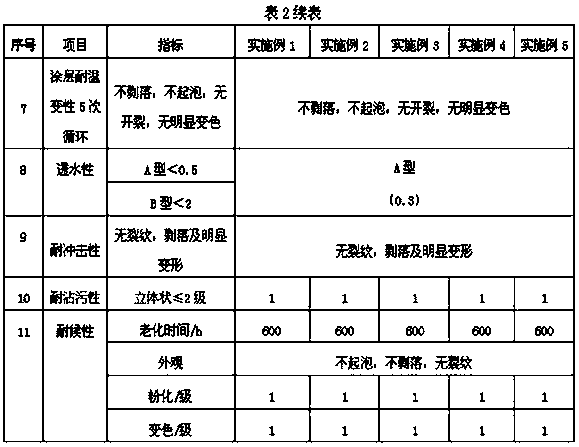

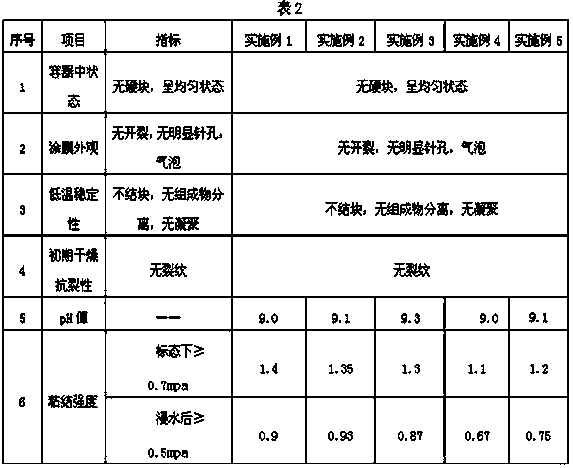

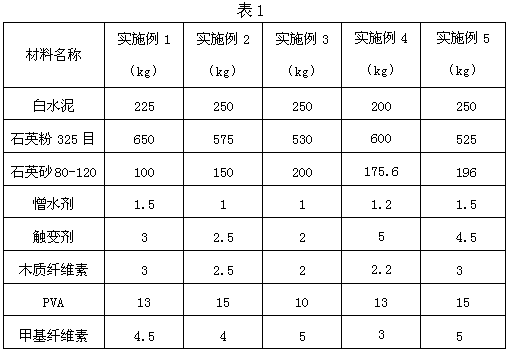

[0044] A kind of relief powder for exterior wall of the present invention, each embodiment concrete implementation component distribution ratio as shown in table 1:

[0045]

[0046] The preparation method of above-mentioned external wall relief powder comprises the steps:

[0047] Turn on the putty powder mixing equipment, put the accurately weighed white cement, quartz powder (4 / 5 of the total mass of the quartz powder), and quartz sand into the feeding port in sequence. After stirring for 3 minutes, add water repellent and thixotropic agent one after another Wood fiber, PVA, methyl hydroxyethyl cellulose, and then put in the remaining quartz powder (1 / 5 of the total mass of the quartz powder), stir for 5 minutes, take out the material from the feeding port, add water 35wt% to measure the consistency of the product, and the temperature The temperature is 25±2°C, the viscosity is 12.5-13.5 rings, and the relief powder for exterior walls can be obtained without any obstacle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com