Oil water well hydraulic expanding tube reshaping and renovation tools

An oil-water well and hydraulic technology, applied in wellbore/well components, earth-moving drilling, etc., can solve problems such as large vibration, low casing success rate, and shaping tools stuck by deformed well sections, and achieve large axial force. , the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

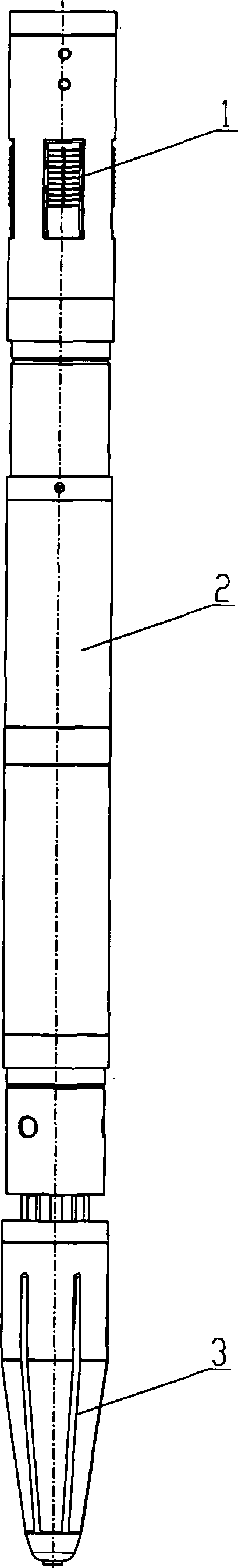

[0009] Among the figures: 1 is an anchor, 2 is a hydraulic pusher, and 3 is a split tube expander. That is, the embodiment of the present invention is composed of an anchor 1, a hydraulic pusher 2, and a split tube expander 3. Upper joint. The connecting threads of the anchor 1, the hydraulic pusher 2, and the split tube expander 3 are drill pipe threads.

[0010] The function of the anchor 1 is to support the shaping pipe string and bear the hydraulic reaction force during shaping. The upper and lower joints of the anchor adopt the drill pipe thread commonly used in the oil field, which is convenient to connect with the drill pipe. The anchor body can be connected in series in multiple stages to provide more reliable and firm support.

[0011] There are hydraulic cylinders and plungers on the hydraulic pusher 2, which are used to generate downward axial thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com