Stable-pressure extraction and washing system for coal-bed gas well without halting production and method

A technology for coalbed methane wells and voltage stabilization, which is applied in earth-moving drilling, well flushing, wellbore/well components, etc., can solve problems affecting coal reservoir permeability, coalbed methane well productivity, high input cost and maintenance cost, well flushing pipe Complex column structure and other problems, to achieve the effect of simple structure, cost saving, and avoiding stuck pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

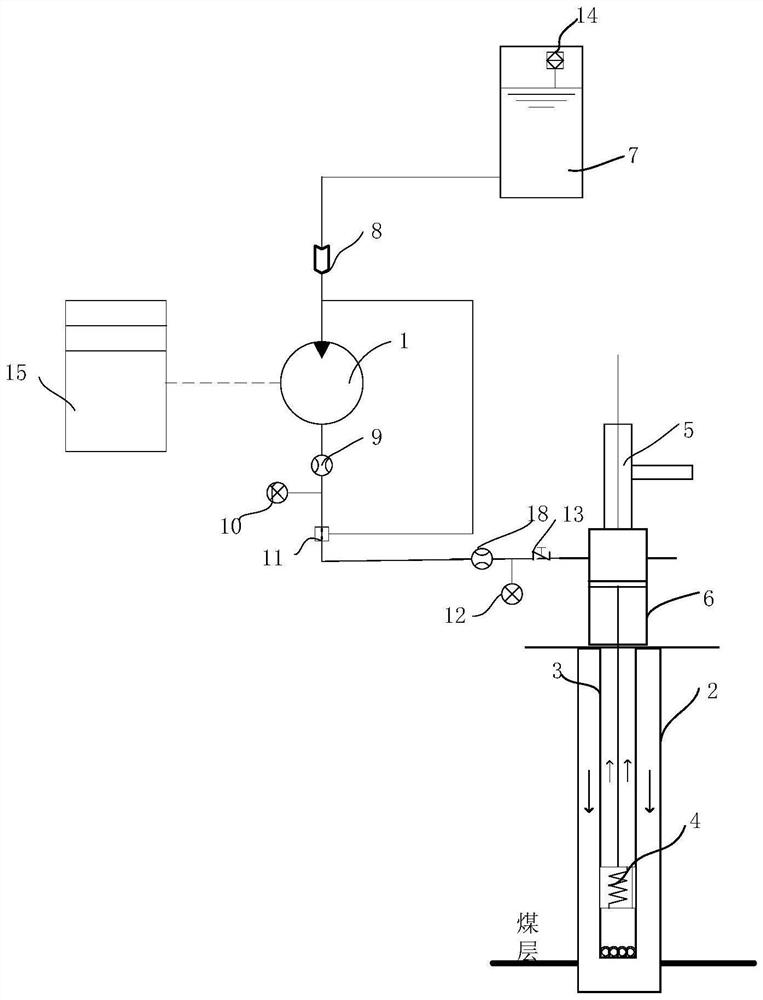

[0032] Embodiment 1, see attached figure 1 , a coalbed methane well non-stop production and pressure stabilization pumping and washing system, which includes: plunger pump 1, oil pipe 3, drainage pump 4 and storage tank 7.

[0033] The oil pipe 3 and the extraction pump 4 are lowered into the wellbore, the oil casing annulus is formed between the oil pipe 3 and the casing 2 in the wellbore, and the oil pipe 3 communicates with the oil casing annulus through the bottom suction port; Structure 5; the first interface of the tee structure 5 is connected to the tubing 3; the output end of the uphole power unit is connected to the extraction pump 4 in the tubing 3 through the third interface of the tee structure 5.

[0034] The reservoir 7 is used to store the washing liquid, and the reservoir 7 is connected to the inlet of the plunger pump 1 through the water inlet pipeline, and a filter 8 is arranged on the water inlet pipeline. A water gauge 14 is provided in the reservoir 7 . ...

Embodiment 2

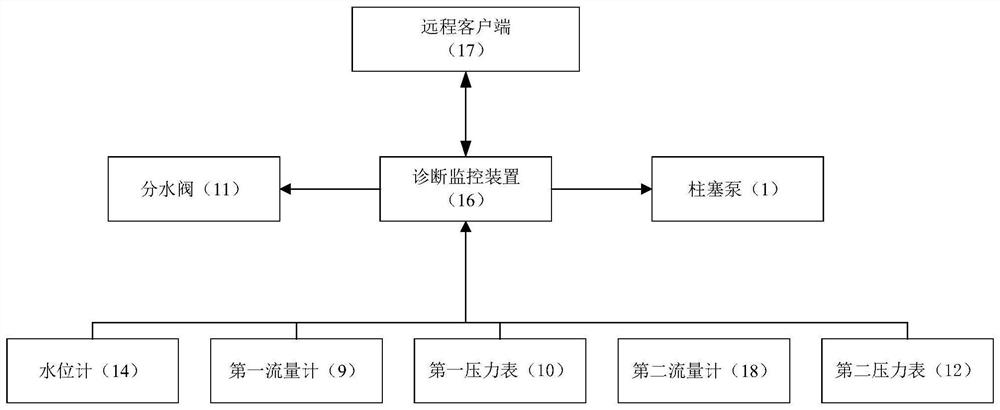

[0041] Embodiment 2, see attached figure 2 , on the basis of Embodiment 1, in order to realize automatic control, the pumping and washing system also includes: diagnostic monitoring device 16; diagnostic monitoring device 16 and water level gauge 14, the first flow meter 9, the first pressure gauge 10, the second flow meter 18. The second pressure gauge 12 establishes a signal connection, which is used to collect the water level in the reservoir 7, the flow and pressure at the outlet of the plunger pump 1, and the pressure in the pumping and washing pipeline; the diagnostic monitoring device 15 and the plunger pump The motor in 1 and the water diversion valve 11 establish a signal connection, and make a comprehensive judgment based on the information collected above, thereby adjusting the frequency of the plunger pump 1 motor and the opening of the water diversion valve 11 .

[0042] Furthermore, the pumping and washing system also includes: a remote client 17; the remote cli...

Embodiment 3

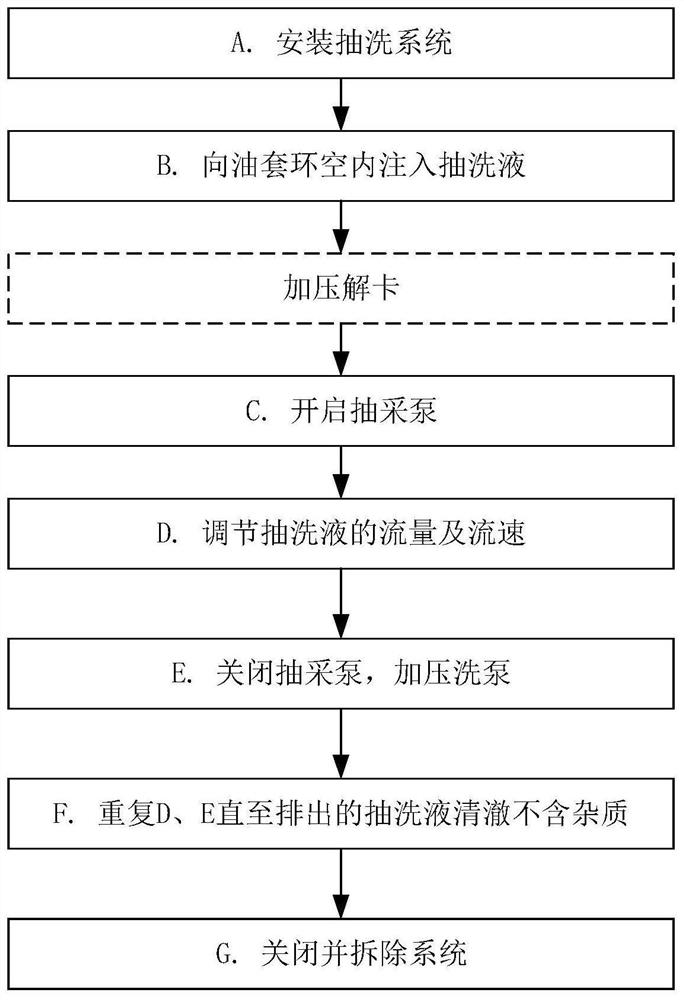

[0043] Embodiment 3, see attached image 3 , a coalbed methane well non-stop production and pressure stabilization pumping and washing method, which is based on the coalbed methane well non-stop production and pressure stabilization pumping and washing system described in embodiment 1 or 2, comprising the following steps:

[0044] A. Install the pumping and washing system;

[0045] B. Turn on the plunger pump 1, and under the action of the plunger pump 1, the washing liquid in the reservoir 7 is filtered and injected into the annulus of the oil jacket;

[0046] C. For the CBM wells in normal operation, start the extraction pump 4, and continue to inject the washing liquid until the washing liquid is discharged from the second interface of the tee structure 5 to the ground;

[0047] D. Through the readings of the first flowmeter 9, the first pressure gauge 10, the second flowmeter 18, and the second pressure gauge 12, adjust the frequency of the plunger pump 1 and the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com