Exhaust gas purification method and exhaust gas purification system

An exhaust gas purification system and technology for exhaust gas purification, which are applied in exhaust treatment, electrical control, exhaust devices, etc., can solve the problems of worsening ride comfort and increasing fuel consumption, reducing exhaust gas volume, inhibiting fuel consumption increase, and effectively regenerating treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

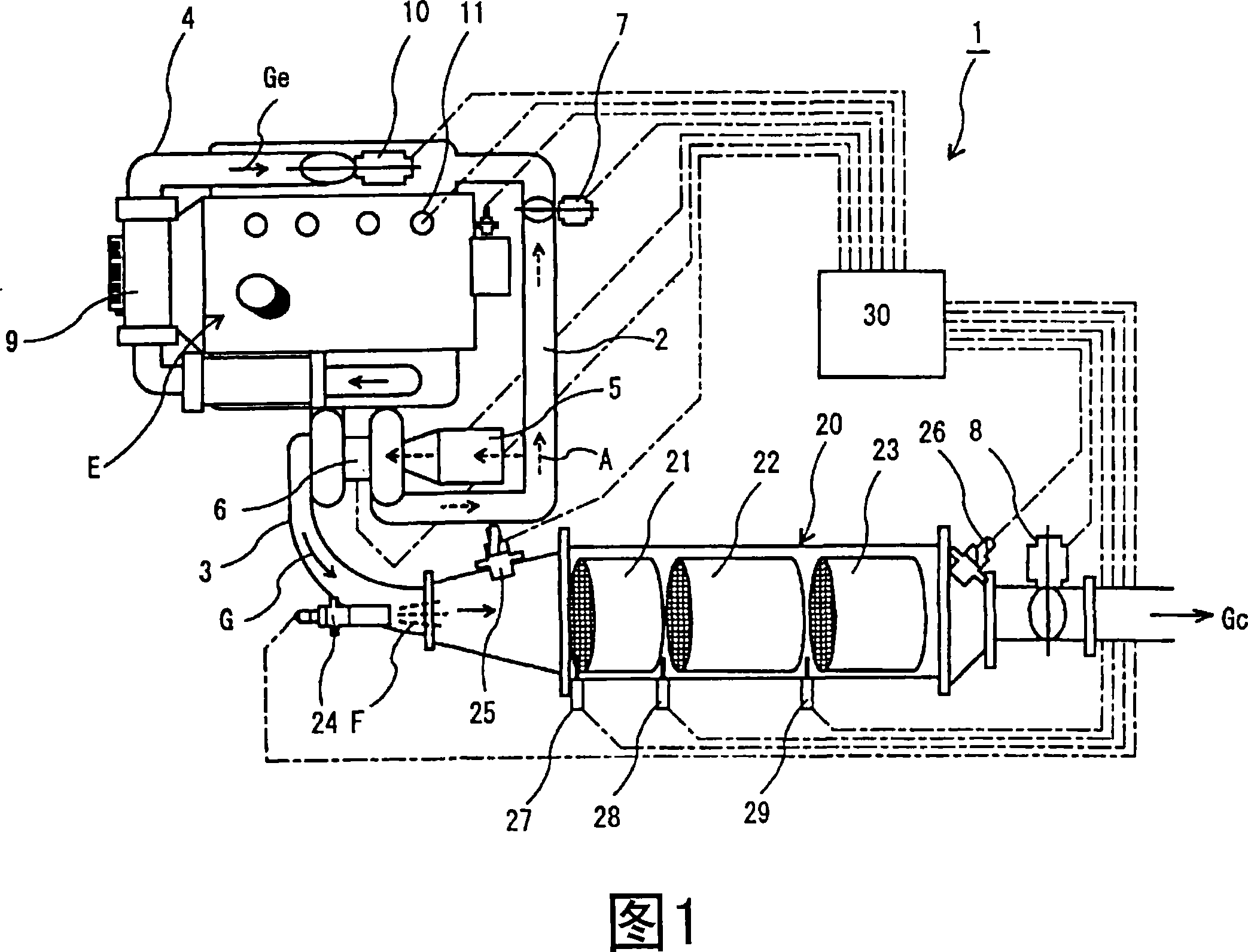

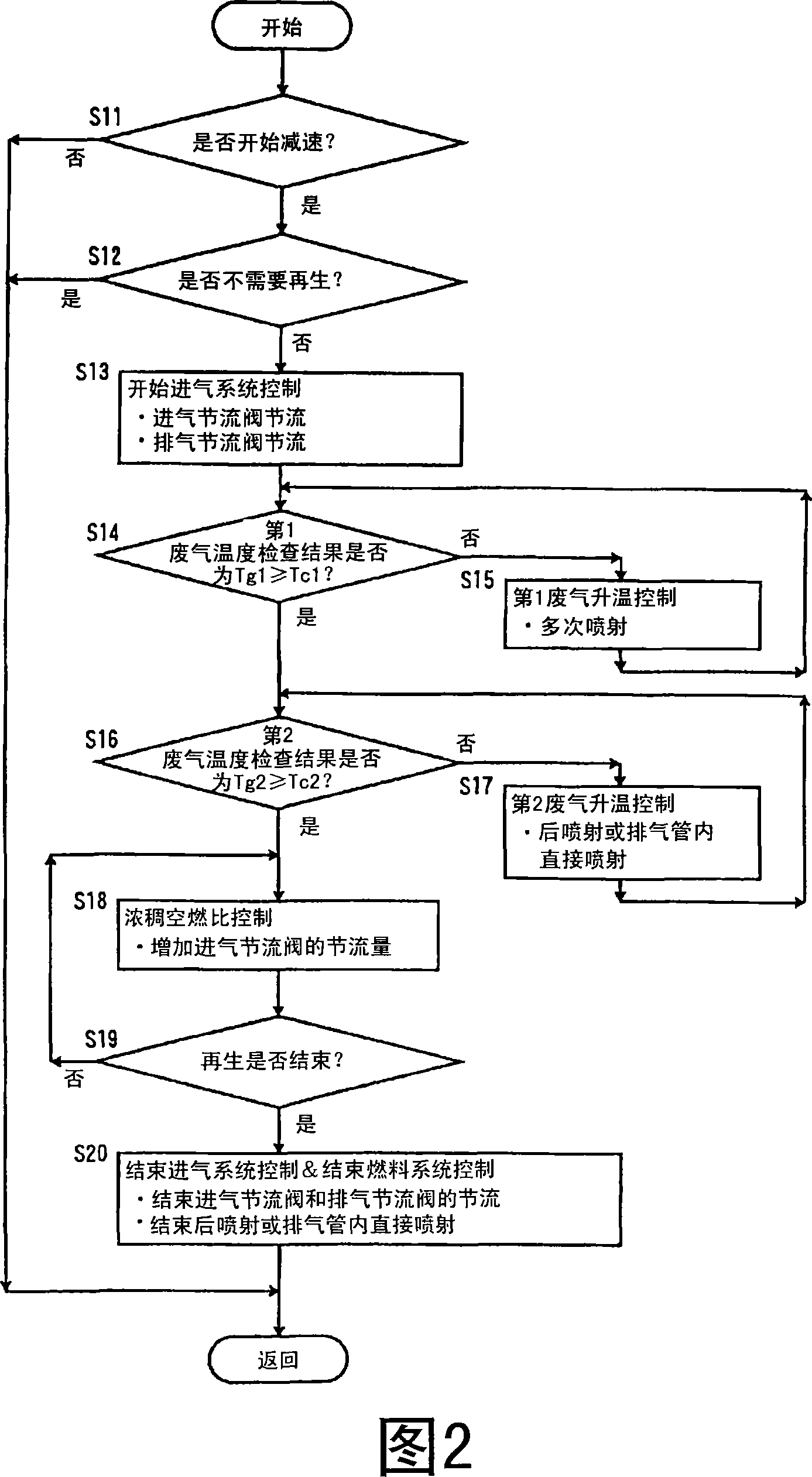

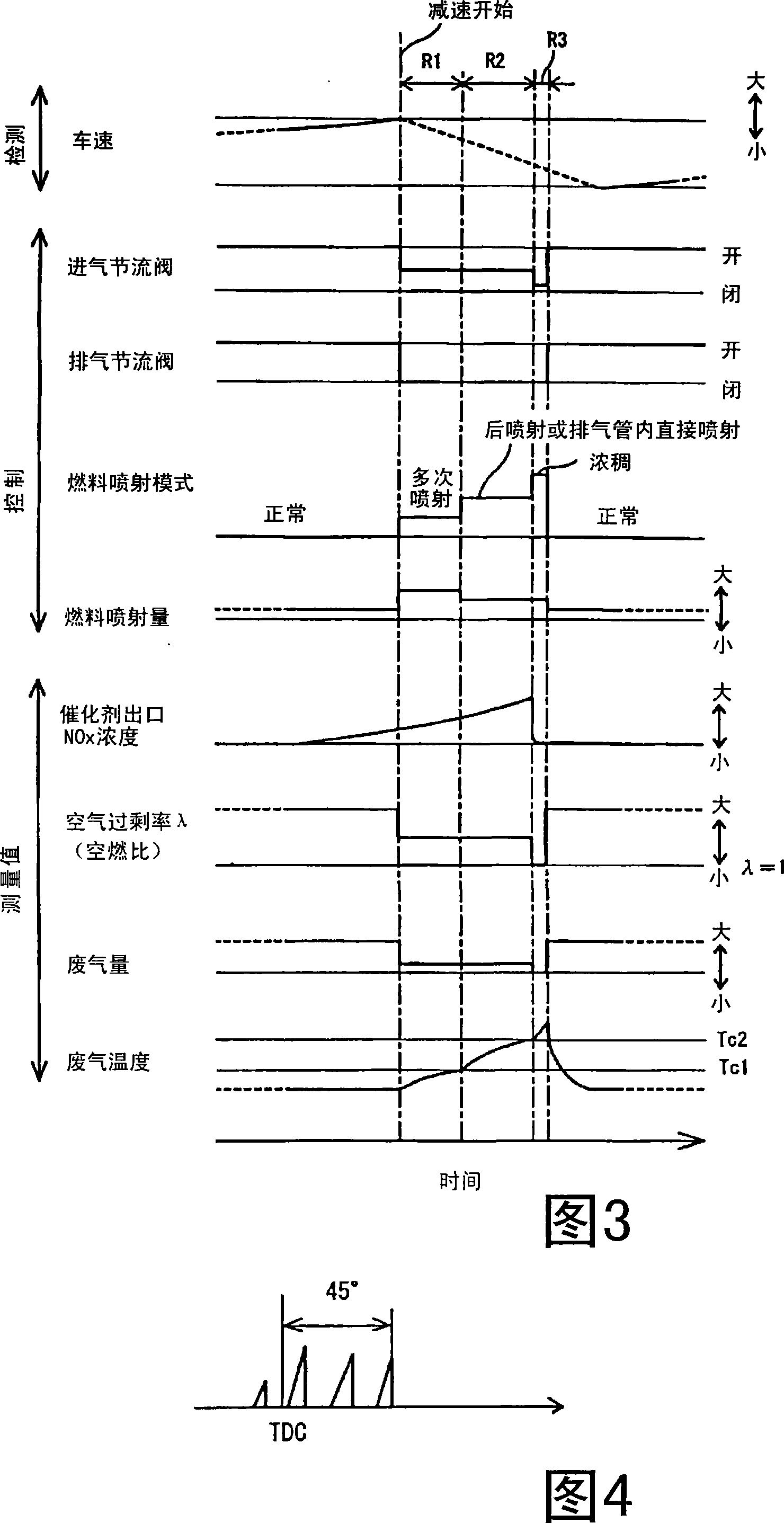

[0045] Hereinafter, an exhaust gas purification method and an exhaust gas purification system according to embodiments of the present invention will be described with reference to the drawings.

[0046] In addition, although NO X storage reduction catalyst as NO X The example of purification catalyst will be described, but the present invention can also be applied to NO X direct reduction catalysts, etc. And, although the recovery of NO in the state of rich air-fuel ratio X The purification ability is mainly used to explain the recovery of NO X NO storage reduction catalyst X occlusion capacity, but the present invention can also use NO X Recovery of occlusion-reduction catalysts from sulfur poisoning, or NO X NO of direct reduction catalyst X Restoration of reducing power or recovery from sulfur poisoning, etc.

[0047] Moreover, the exhaust gas thick state mentioned here does not necessarily have to be rich in combustion in the cylinder, but refers to the exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com