Electric tool

A technology for electric tools and front ends, which is applied in the direction of motor tools, manufacturing tools, portable motor devices, etc., can solve the problems that the output shaft cannot be shortened, the compactness limit of the front and rear lengths, etc., and achieve good operability and workability, and good operation Sexuality, the effect of a simple swipe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

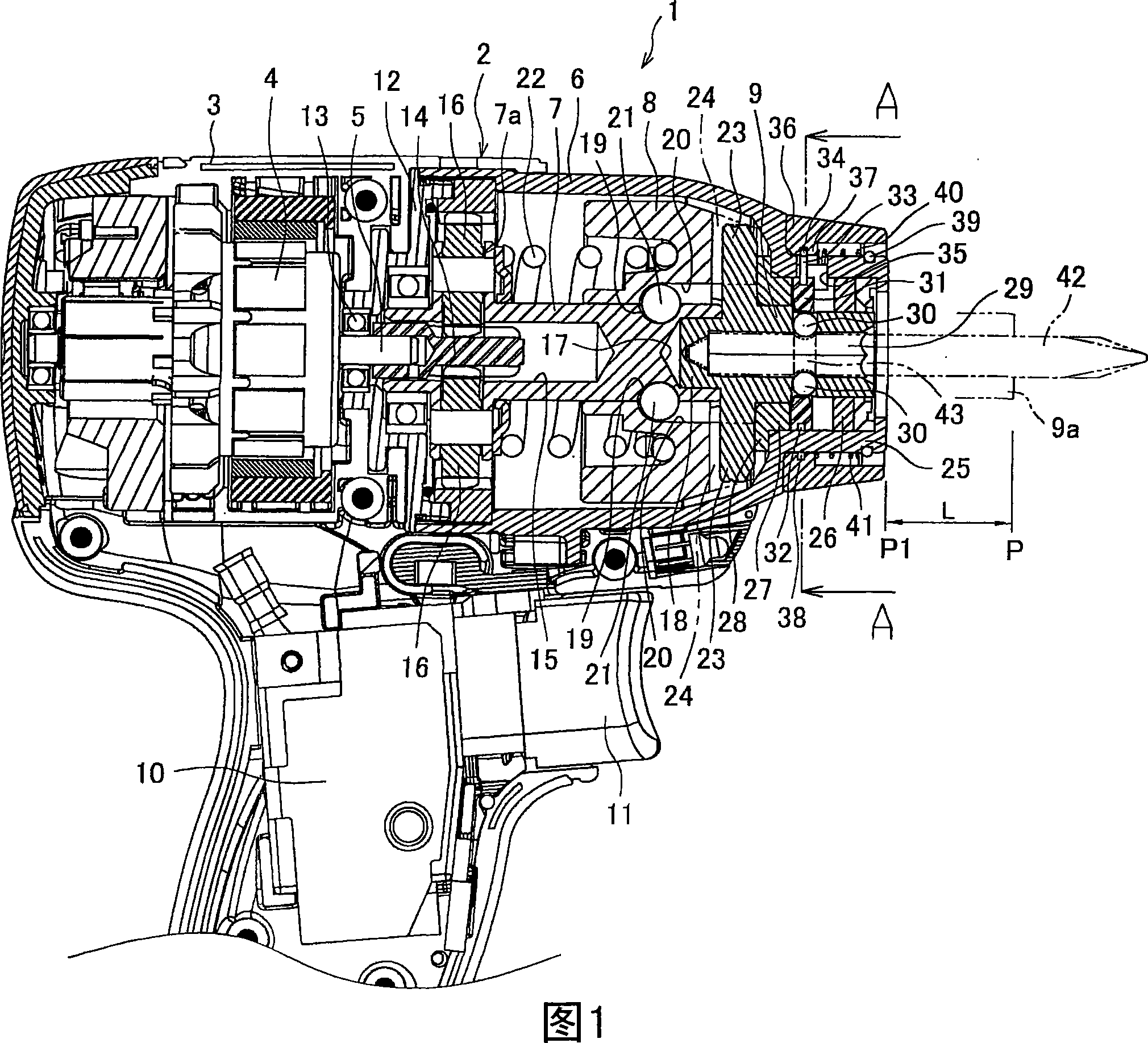

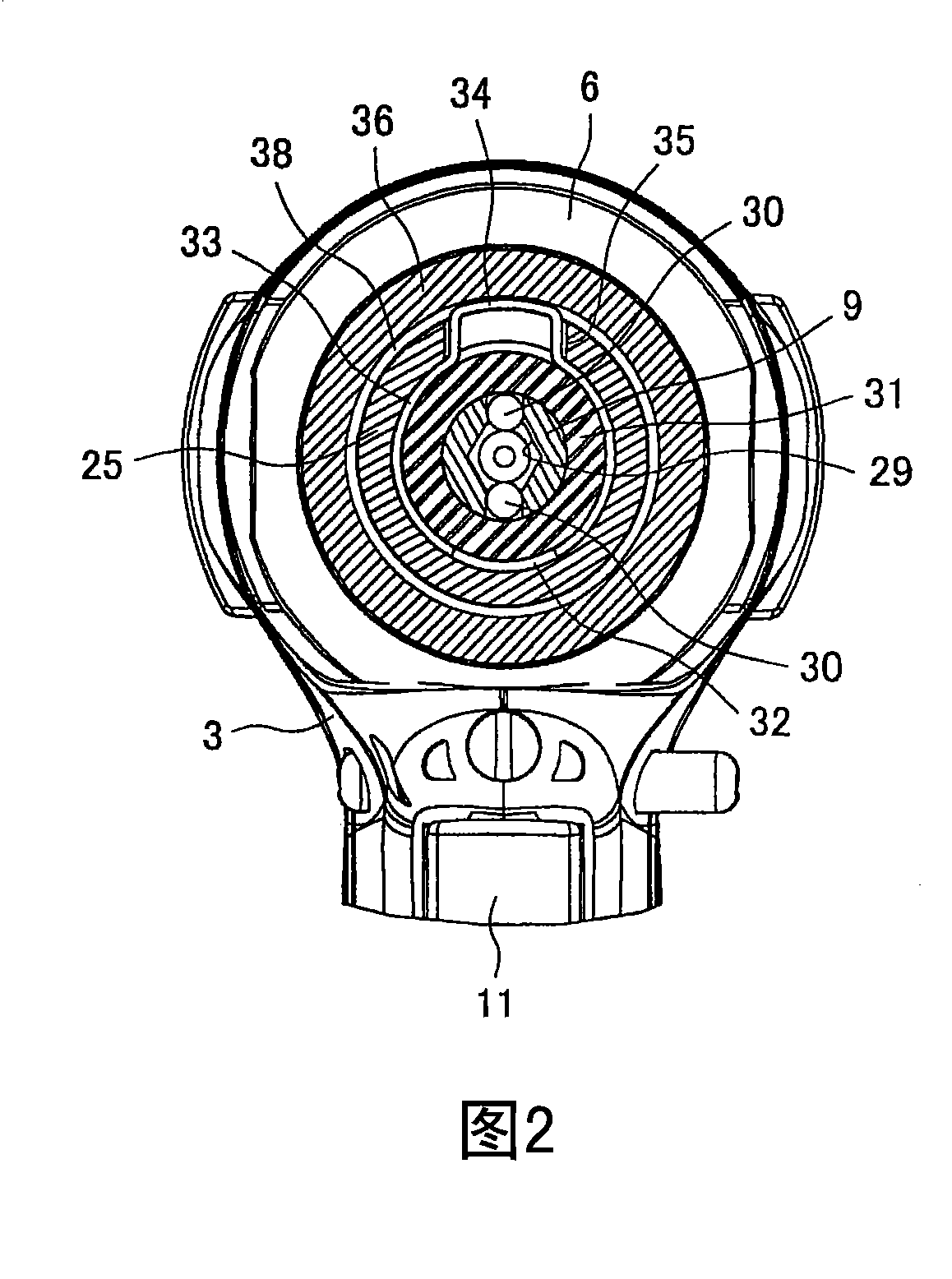

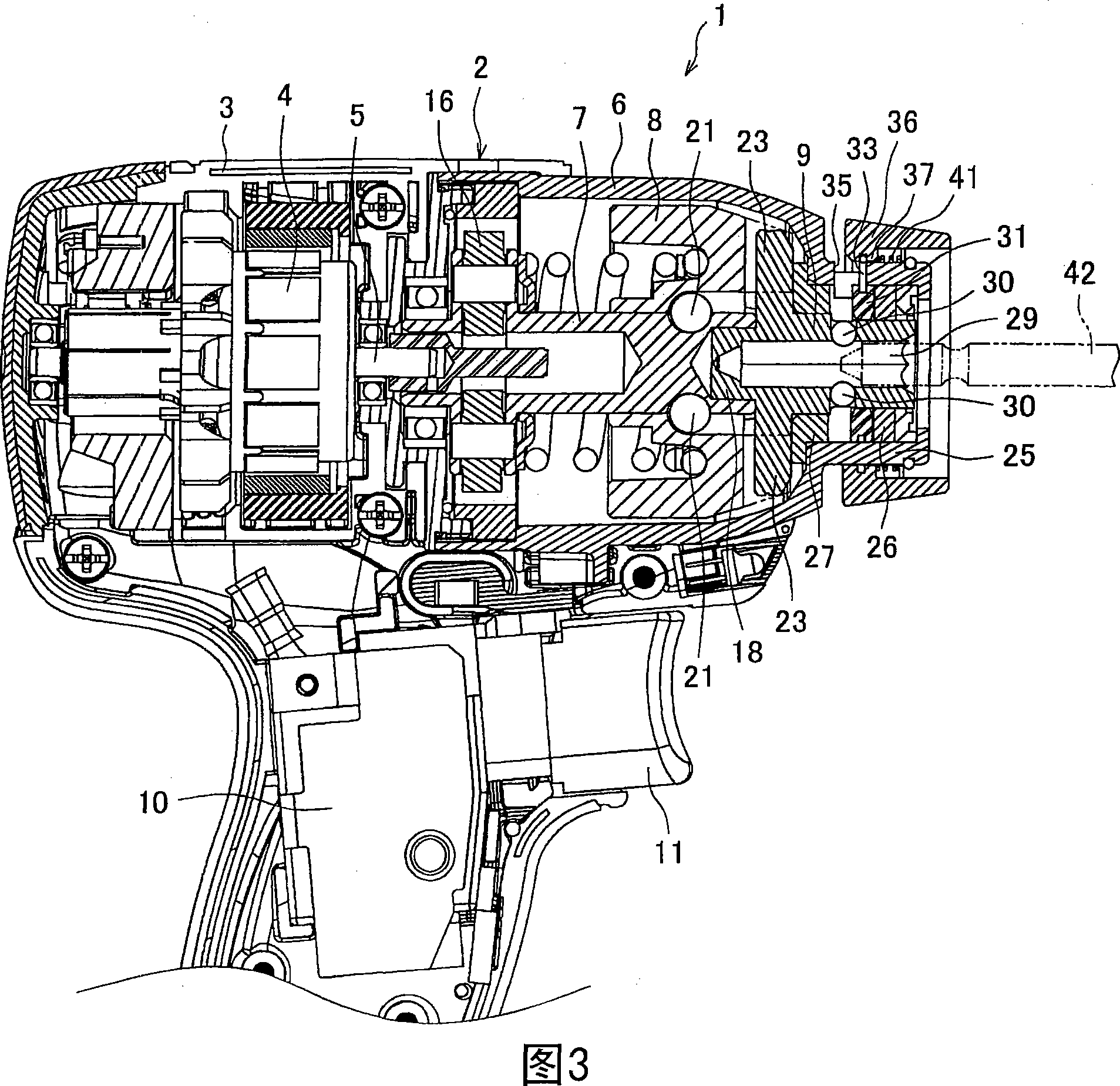

[0016] Embodiments of the present invention will be described below with reference to the drawings.

[0017] figure 1 It is a partial longitudinal sectional view of an impact screwdriver as an example of an electric tool. The main body 2 of the impact screwdriver 1 is formed by installing a hammer housing 6 in front of a main body housing 3 housing a motor 4. The hammer housing 6 accommodates a main shaft 7, a hammer 8, an anvil 9 serving as an output shaft, and the like. 10 is a switch for driving the motor 4, and 11 is a trigger for turning the switch on / off.

[0018] The gear box 12 is interposed between the main body housing 3 and the hammer housing 6, and the gear box 12 supports the motor shaft 5 of the motor 4 through a ball bearing 13, and makes the pinion gear 14 embedded on the motor shaft 5 The inside of the hammer housing 6 protrudes. The motor shaft 5 and the pinion 14 are loosely inserted into the hollow portion 15 formed at the rear end of the main shaft 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com