Shell pipe heat exchanger

A shell-and-tube heat exchanger, shell-and-tube technology, applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low heat transfer coefficient, heat exchanger failure, cracks in welds, etc. To achieve the effect of increasing the heat exchange area, prolonging the service life and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

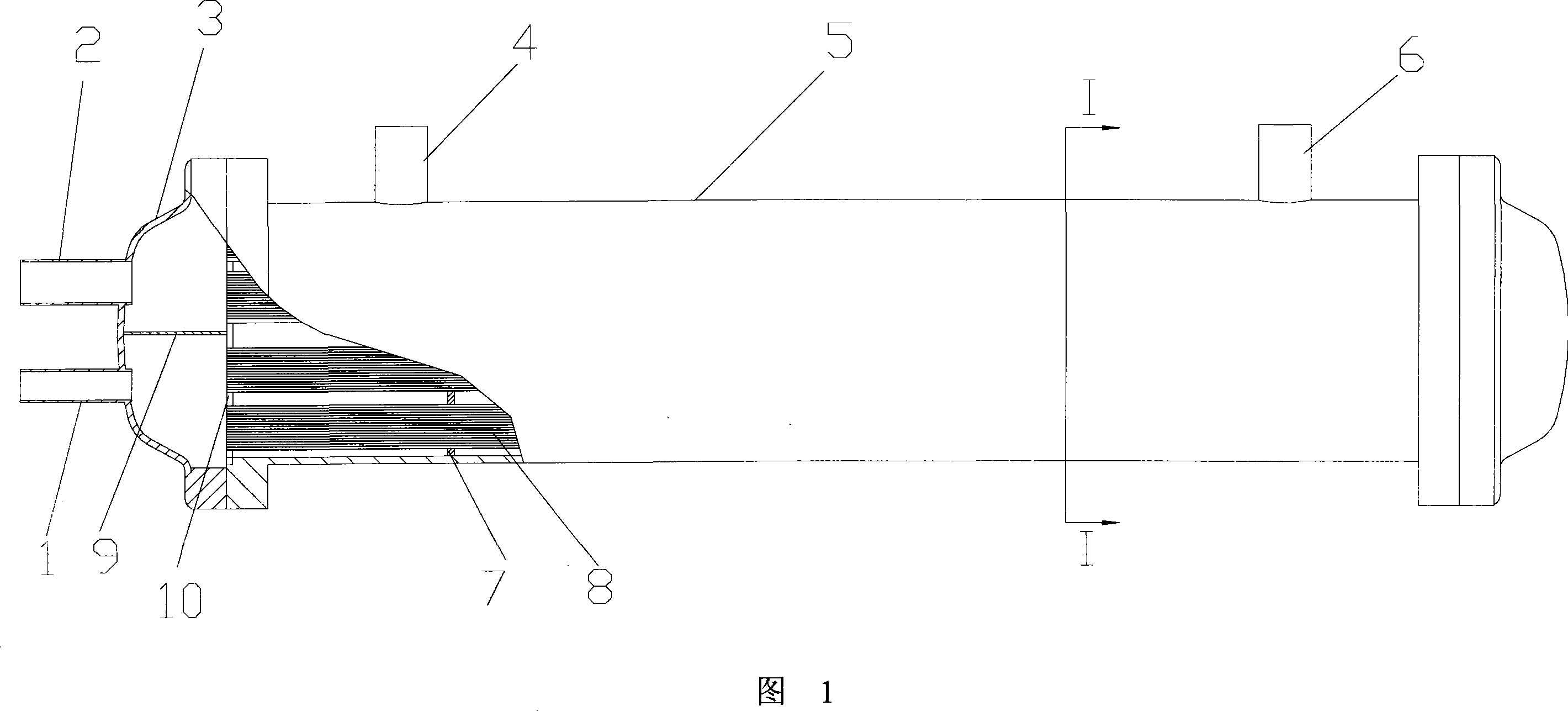

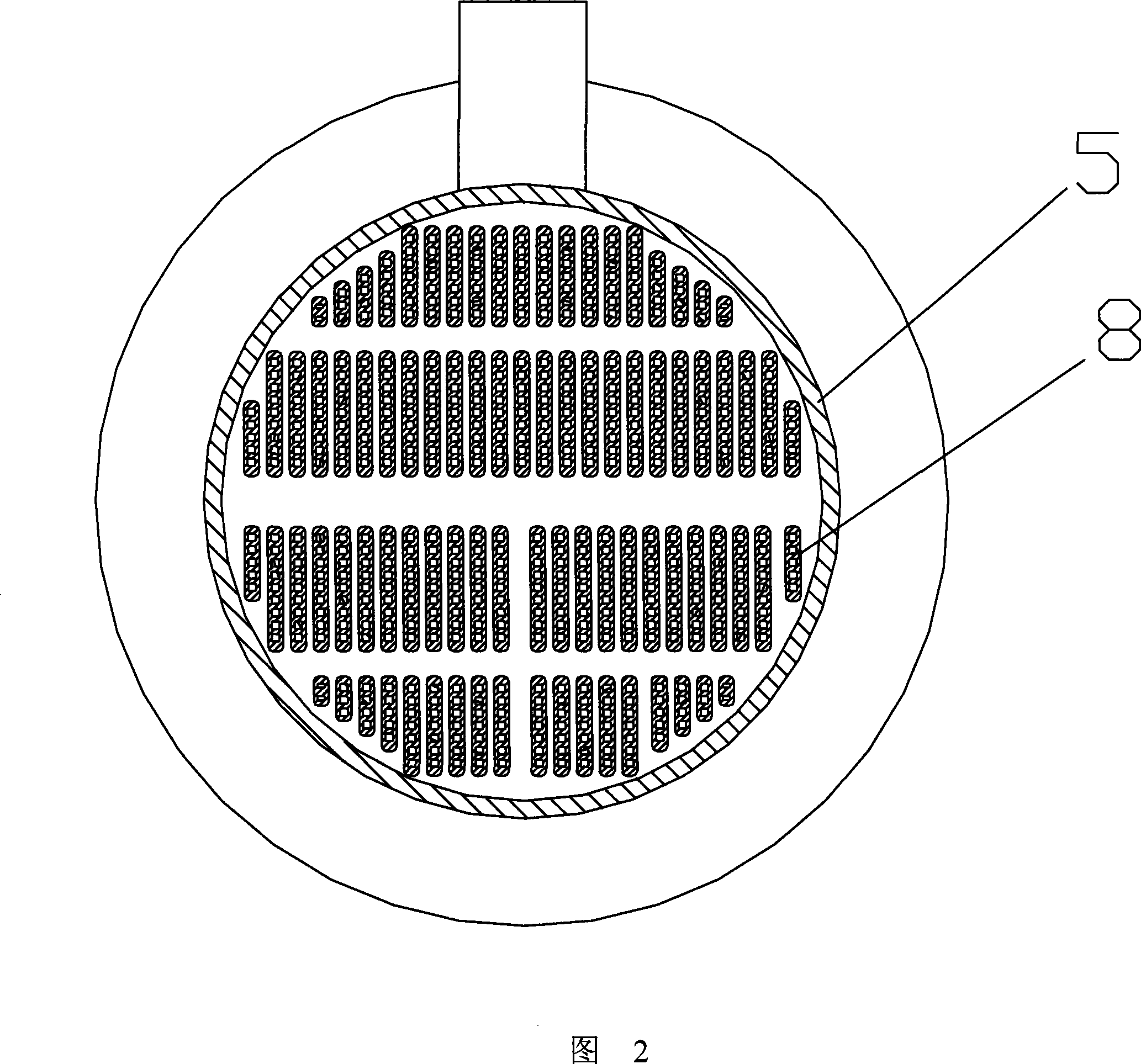

[0014] Embodiment: As shown in Figure 1 and Figure 2, a shell and tube heat exchanger includes a shell tube 5 and end caps 3 at both ends of the shell tube 5 in the axial direction. A plurality of parallel tube bundles 8 and tube sheets 10 connected to both ends of the tube bundles 8, the end cover 3 is provided with a tube-side inlet 2 and a tube-side outlet 1, and the tube shell 5 is provided with a shell-side inlet 4 and shell side exit 6.

[0015] There is also a baffle 9 between the end cover 3 and the tube sheet 10 on the same side, which divides the space between the end cover 3 and the tube sheet 10 into several separate cavities, so that the circulation of the fluid in the heat exchange flat tube is divided into Several tube passes are added, which is more conducive to heat exchange.

[0016] In order to increase the flow velocity of the fluid in the shell side and enhance the disturbance, several baffles 7 are arranged on the entire length of the shell tube to defle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com