Temperature sensing element of automatic spraying firefighting apparatus

A technology of fire extinguishing device and temperature sensing element, which is applied in fire rescue and other directions, can solve the problems that the glass ball nozzle cannot be directly replaced, the fusible metal is prone to creep, and affects the reliability of the action, etc., and achieves simple structure, easy processing, and responsive short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

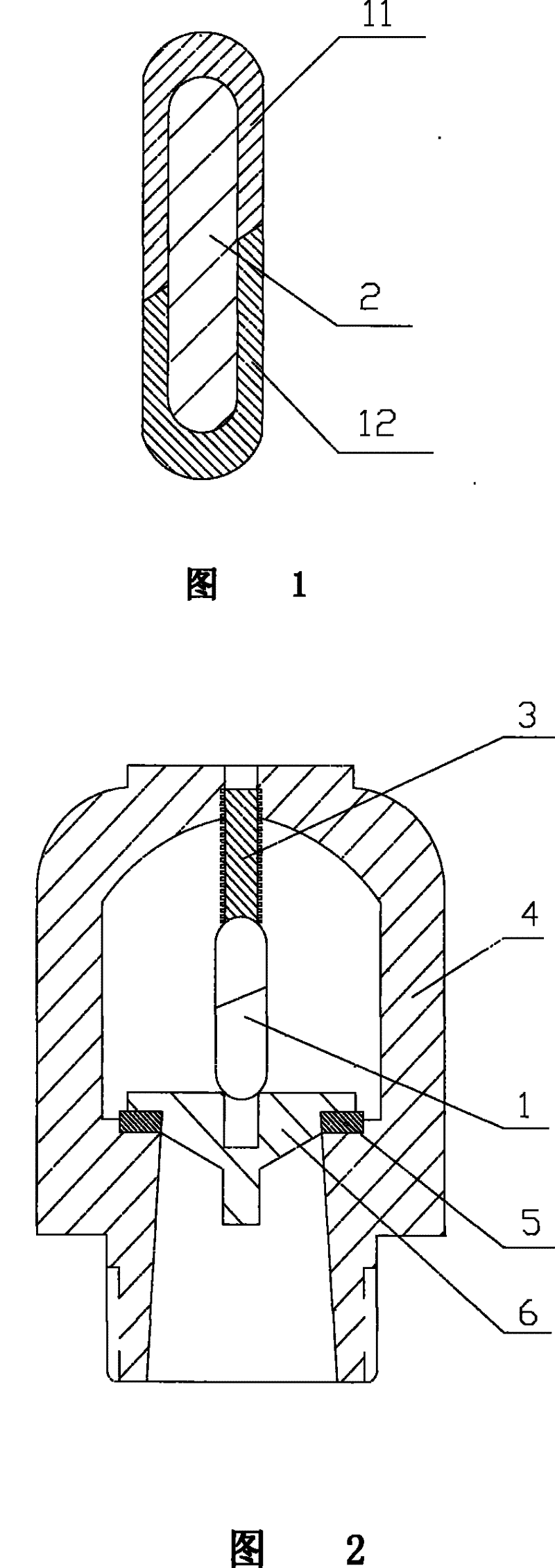

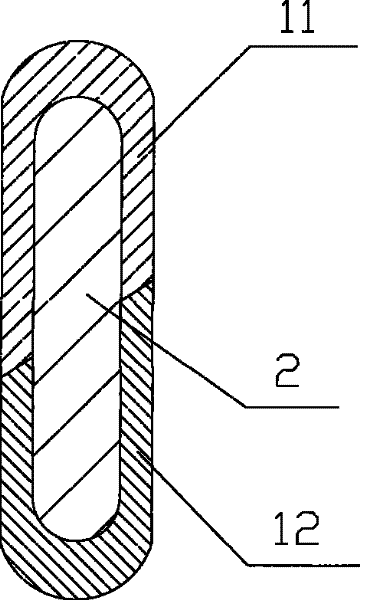

[0020] Such as figure 1 As shown, the temperature sensing element 1 of the sprinkler device of the present invention includes two ceramic shells 11, 12 and fusible alloy 2, and the ceramic shells 11, 12 are cylindrical with one end closed, and one end is hemispherical. The other end is an inclined plane, and the above-mentioned ceramic shells 11 and 12 are matched and connected through the inclined plane, and the fusible alloy 2 is arranged in the ceramic shell.

[0021] The contact surface between the above two ceramic shells 11 and 12 is covered with fusible alloy 2 . The included angle between the inclined planes of the ceramic shells 11, 12 and the cylindrical geometric axes of the ceramic shells 11, 12 is 30-60 degrees, referred to as the bevel angle. The above-mentioned eutectic alloy 2 includes at least three kinds of bismuth, lead, tin, cadmium and antimony materials.

[0022] In the present invention, fusible alloy is used as the temperature sensing material, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com