Cleaning apparatus for discharge nozzle

A technology for cleaning devices and nozzles, applied in the direction of spraying devices, etc., can solve problems such as high cost, high operating cost, and large-scale devices, and achieve the effects of reducing equipment costs, reducing operating costs, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, a nozzle cleaning device according to a reference embodiment of the present invention will be described with reference to the drawings, and then a nozzle cleaning device according to an embodiment of the present invention which is further improved on the nozzle cleaning device according to this reference embodiment will be described in detail. The nozzle cleaning device of the present invention is not limited to the following embodiments, and can be appropriately modified and implemented without changing the gist of the invention.

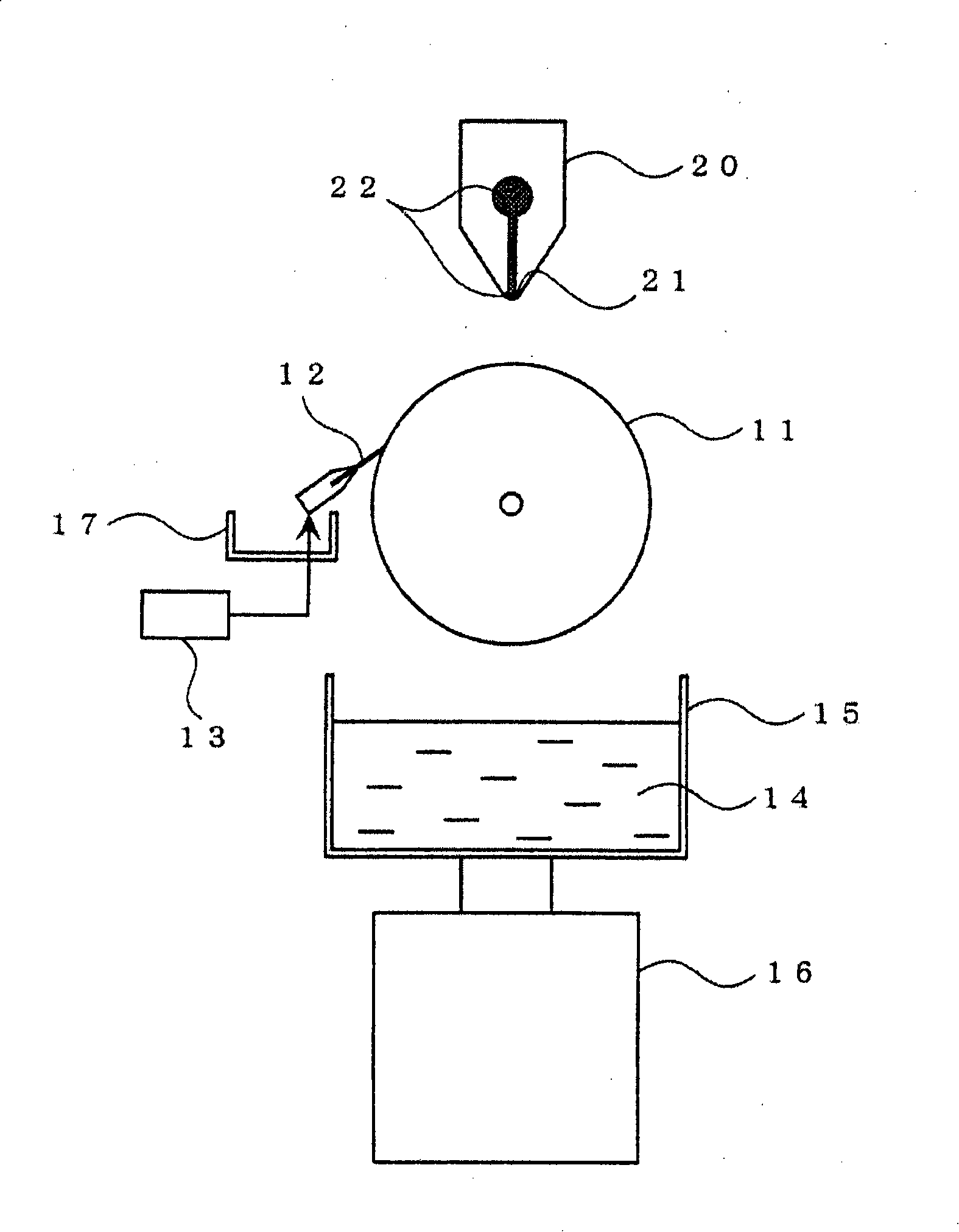

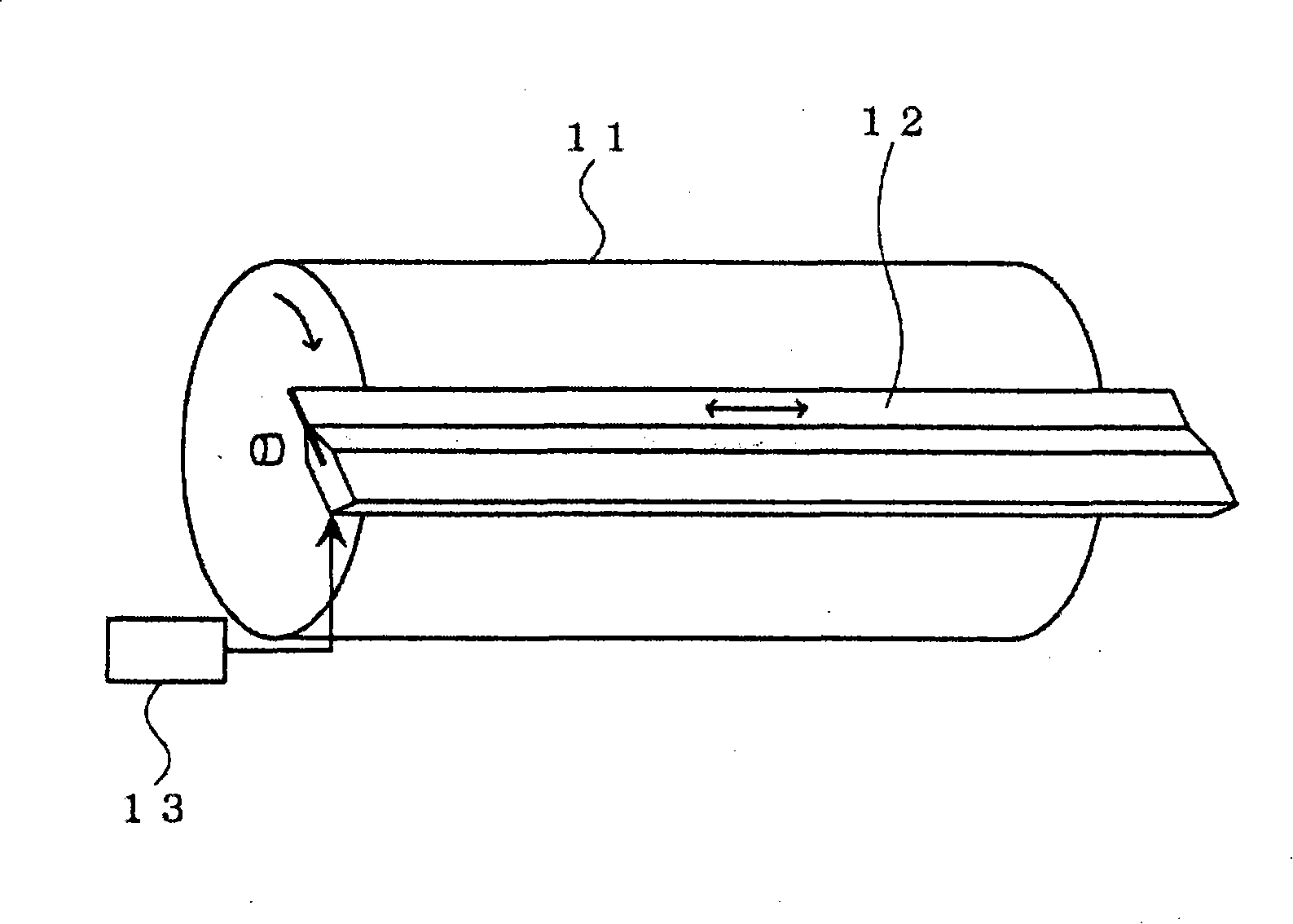

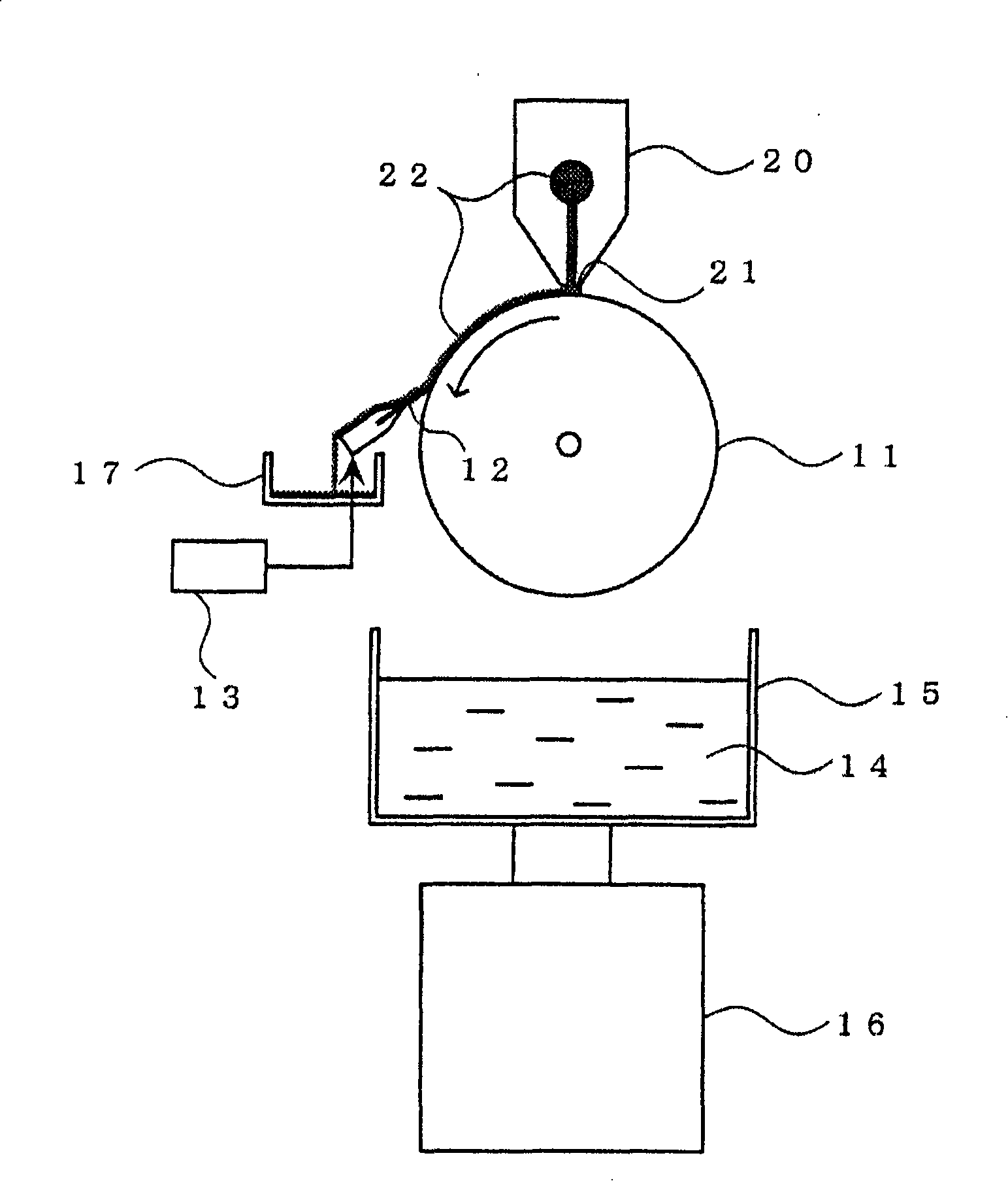

[0036] Such as Figure 1 ~ Figure 4 As shown, in the nozzle cleaning device of the reference form, a scraper 12 whose front end is in contact with the outer peripheral surface of a rotating roller 11 that is rotationally driven by a rotating device (not shown) is provided. In the state where the outer peripheral surface of the figure 2 As shown, the scraper 12 can be reciprocated in the axial direction of the rotating roller 11 by us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com