Enclosed stainless steel train windscreen

A stainless steel, fully-sealed technology, used in windshields installed between carriages and train windshields, can solve the problems of pull-off, short service life, poor sound insulation and heat insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

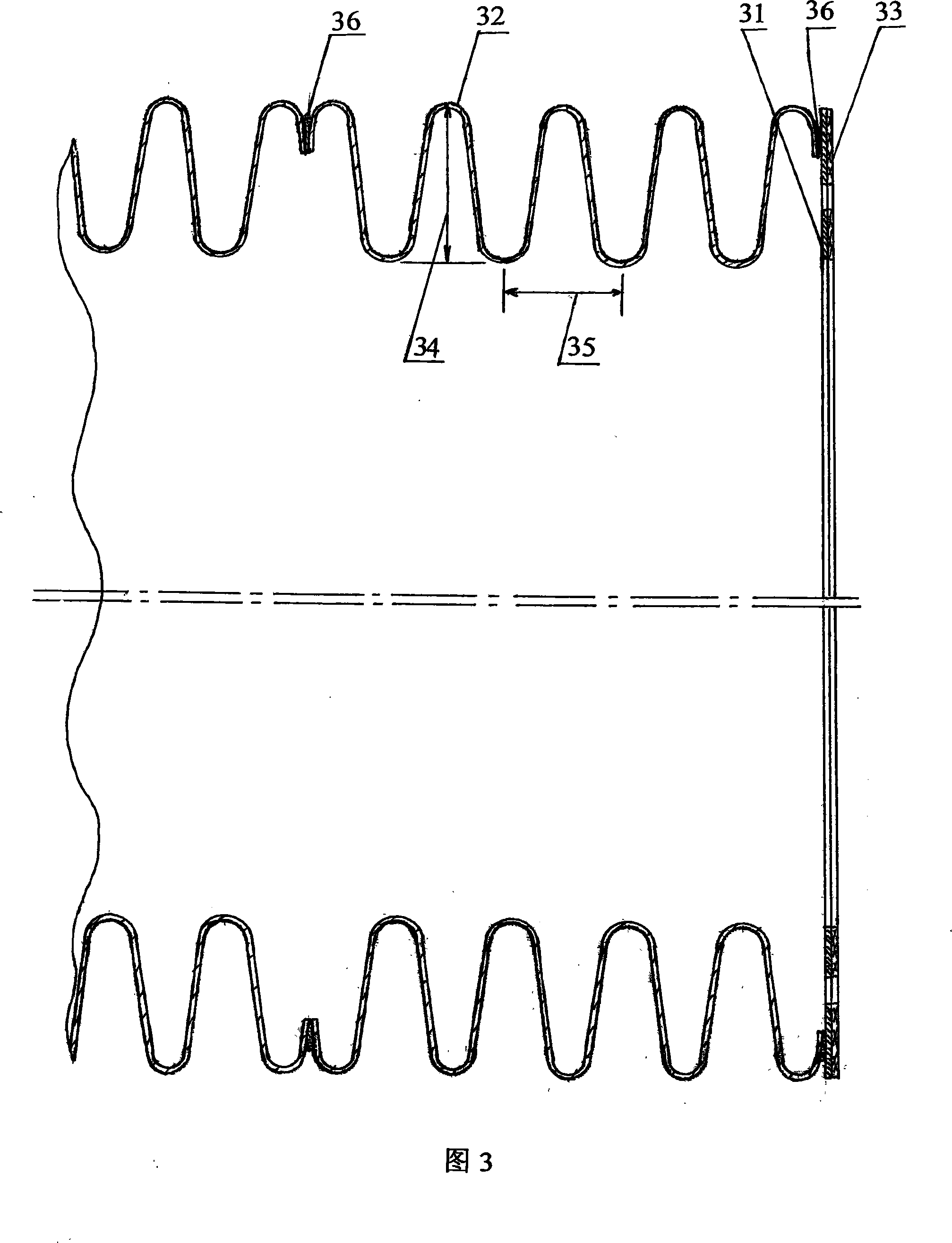

[0016] The windshield of the present invention is further described as follows in conjunction with the accompanying drawings:

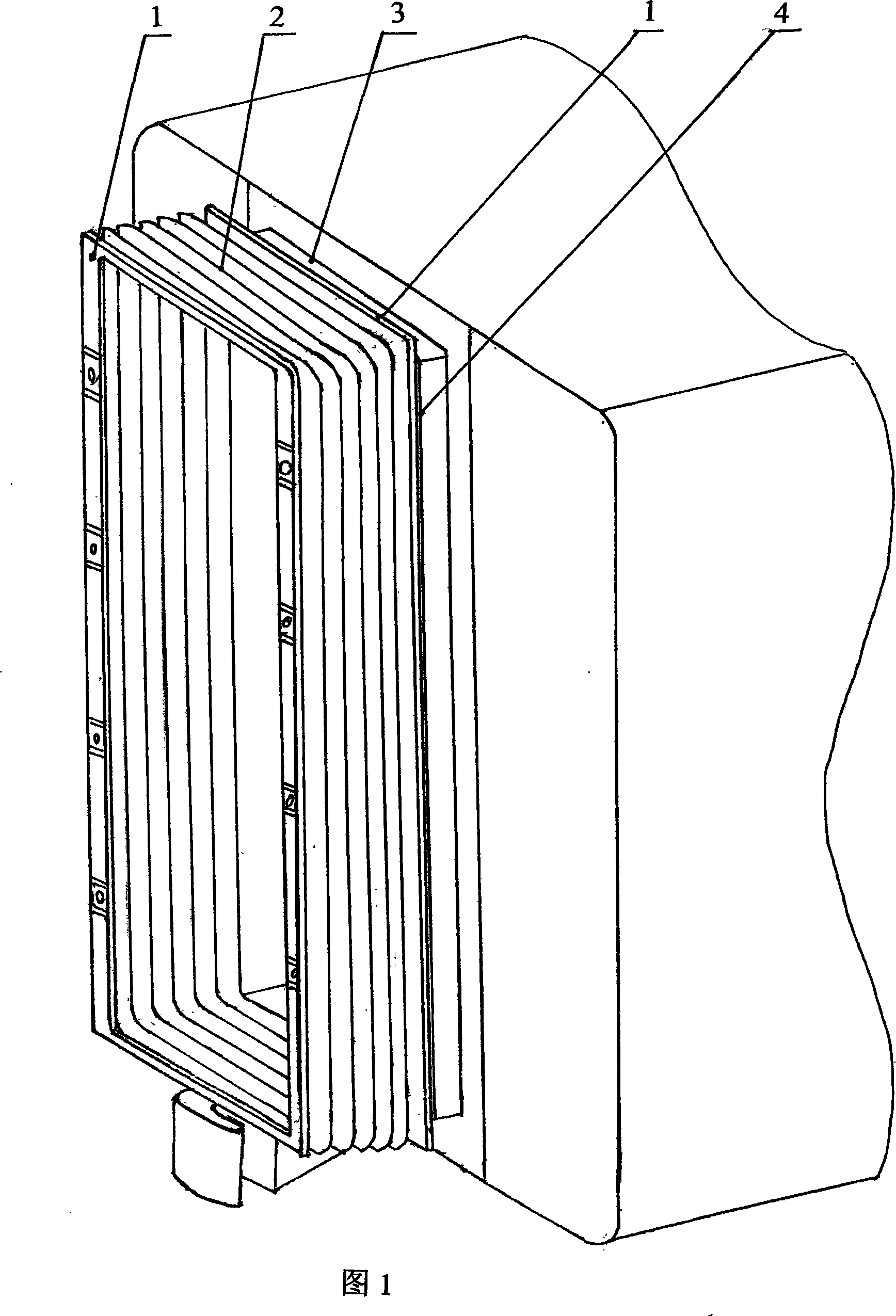

[0017] The windshield of the present invention can be made into a narrow windshield similar to a common windshield, and can also be made into a wide windshield basically consistent with the width of the compartment. Among them, the basic structure of the narrow windshield is shown in Figure 1, mainly composed of a narrow square multi-wave number stainless steel expansion joint 2 corresponding to the width of the compartment opening 3 and a narrow square flange 1, and the narrow square flange 1 ring Welded on both ends of the narrow square multi-wavenumber stainless steel expansion joint 2. During installation, a narrow square gasket 4 can be added at the end of the narrow square flange 1 .

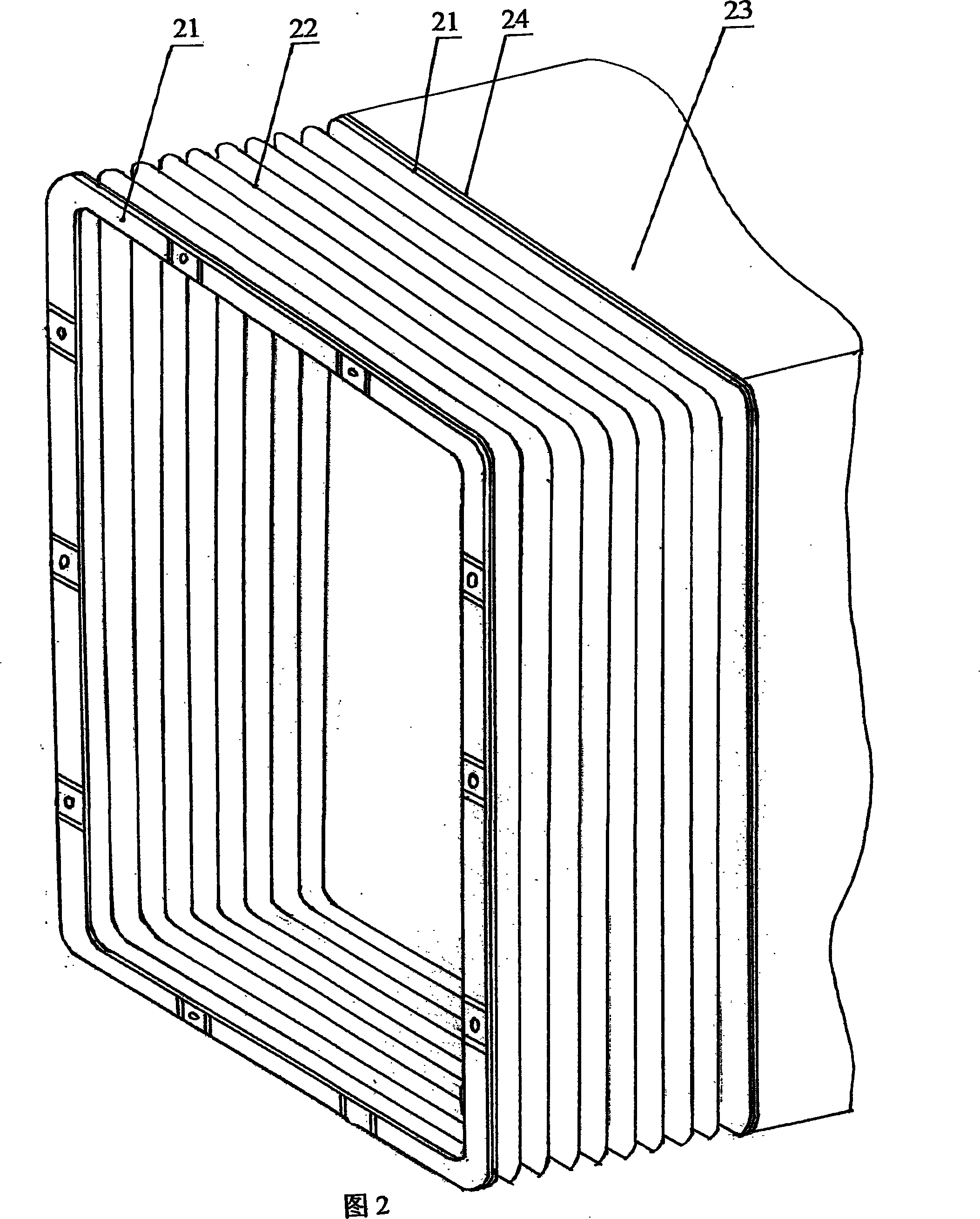

[0018] Referring to accompanying drawing 2, the structure of the wide windshield of the present invention is mainly made of wide square multi-wavenumber stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com