High efficiency diesel pile hammer and gas piston structure thereof

A technology of piling hammer and piston, which is applied in foundation structure engineering, sheet pile wall, construction, etc., and can solve problems such as insufficient fuel combustion, high exhaust gas ratio, reduction of effective compression stroke of cylinder hammer sleeve and piston, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

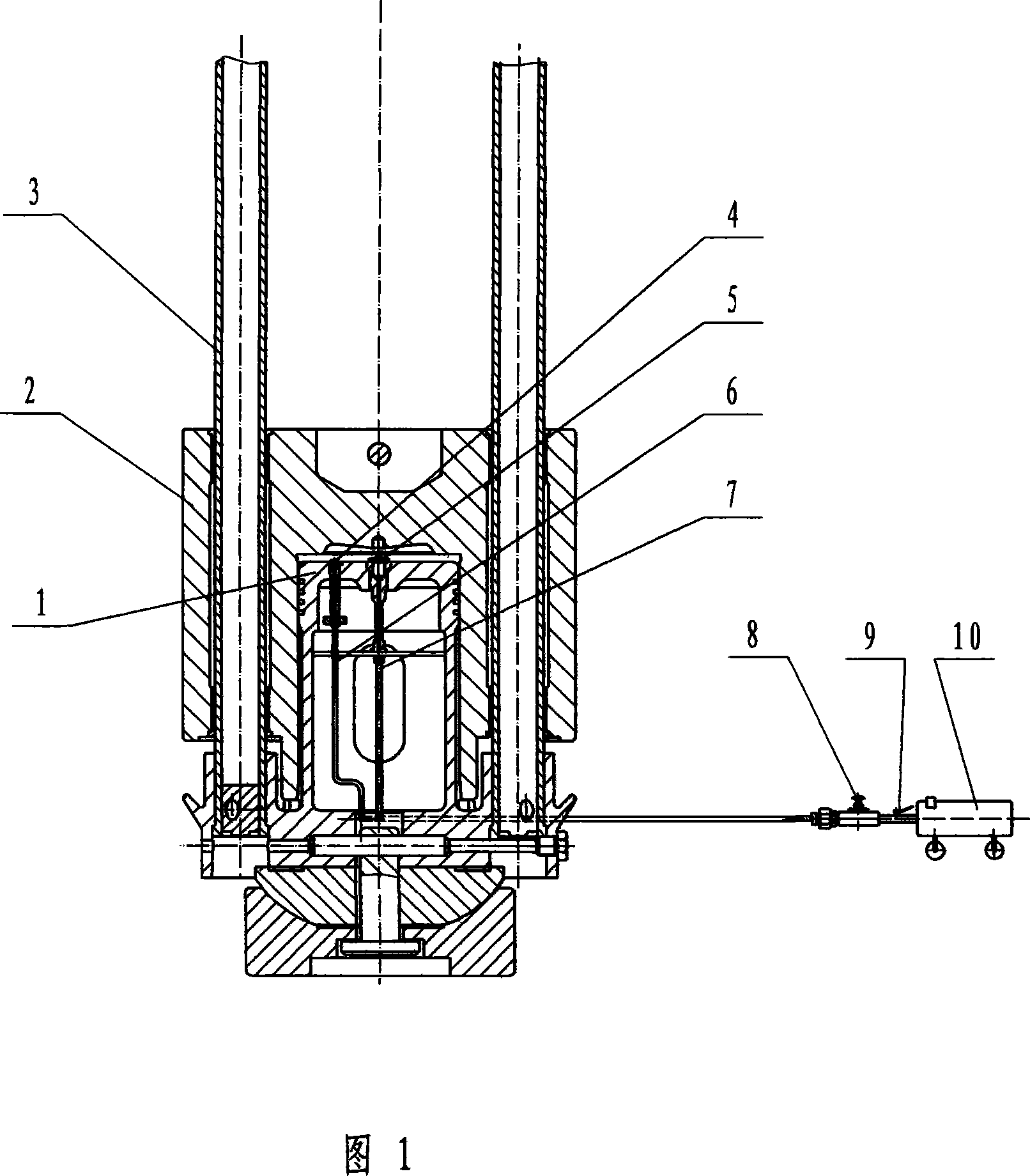

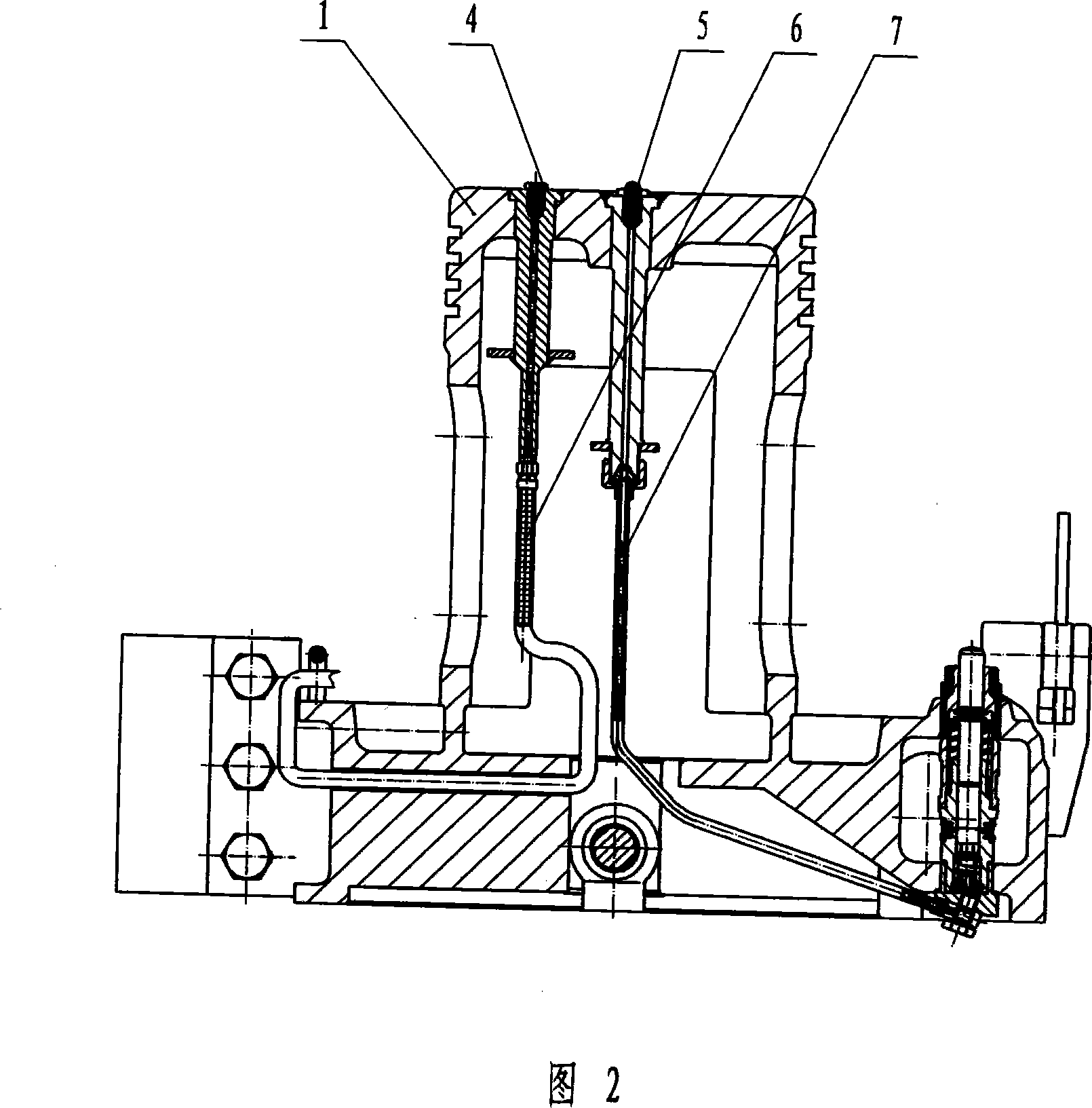

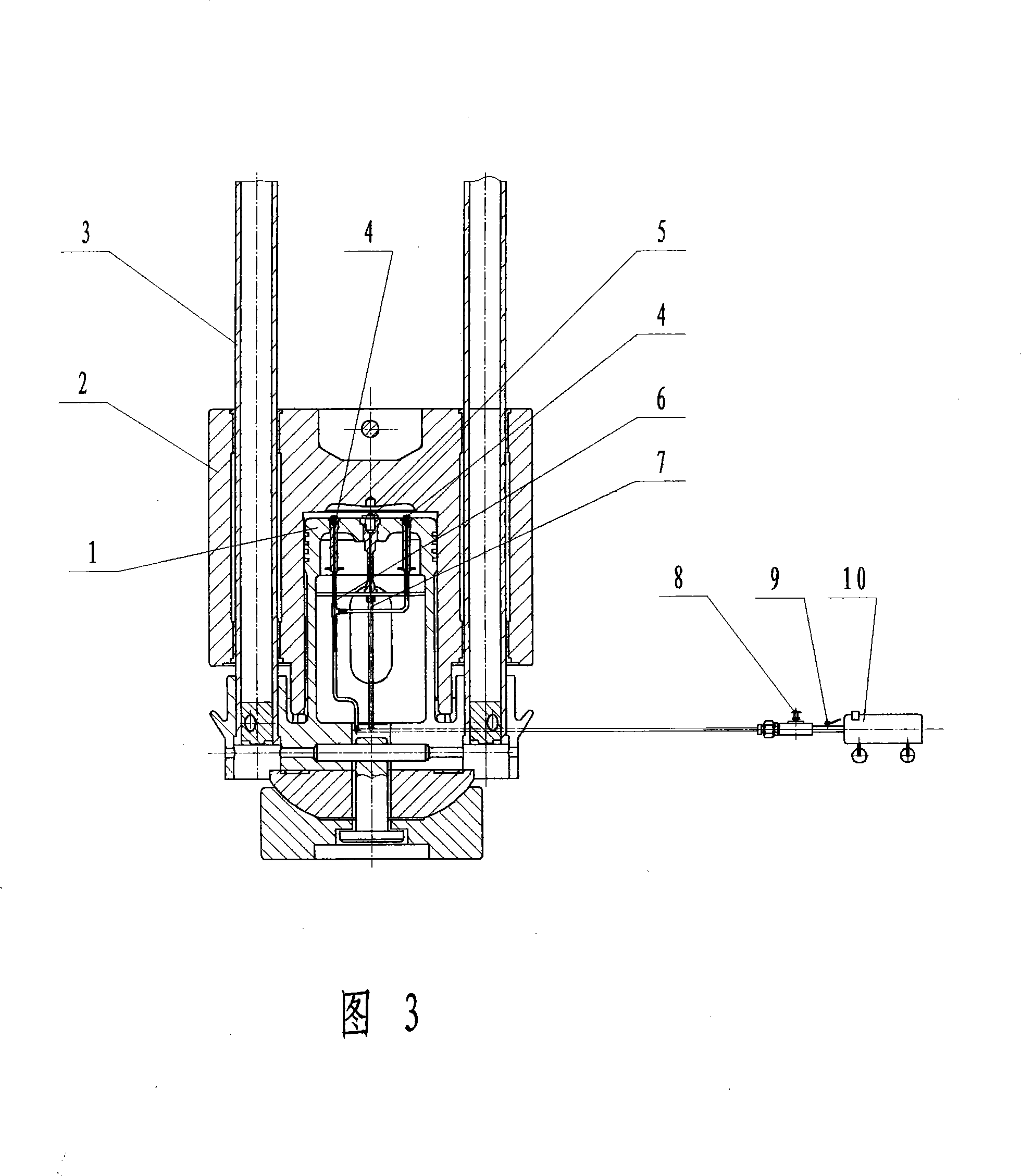

[0014] In the high-efficiency diesel piling hammer shown in Figure 1, the piling hammer includes a piston 1 and a cylinder hammer 2. Two guide rods 3 parallel to each other are fixedly connected to the seat of the piston 1. A cylindrical hollow tube, the cylinder hammer 2 is sleeved on the two guide rods 3 in a reciprocating and bouncing manner through a sliding bearing pad fixed thereon. When the cylinder cavity on the cylinder hammer 2 is sleeved on the piston 1, a closed cylinder cavity is formed to form a fuel combustion chamber. The bottom of the piston 1 is sequentially fixedly connected with a pile cap seat, a pile cap and a pile guard.

[0015] An air nozzle 4 and an oil injection nozzle 5 are arranged on the top working surface of the piston 1 , the oil injection nozzle 5 is located at the center line of the piston 1 , and the air injection nozzle 4 is located outside the oil injection nozzle 5 . The fuel injection nozzle 5 is connected to the oil pipe 7, and the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com