Return-flow system of ball screw rod

A ball screw and screw technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of enlarged steering path, affecting the relationship of circular motion, and reducing the mechanical efficiency of ball screw, so as to increase the radius of curvature, The effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

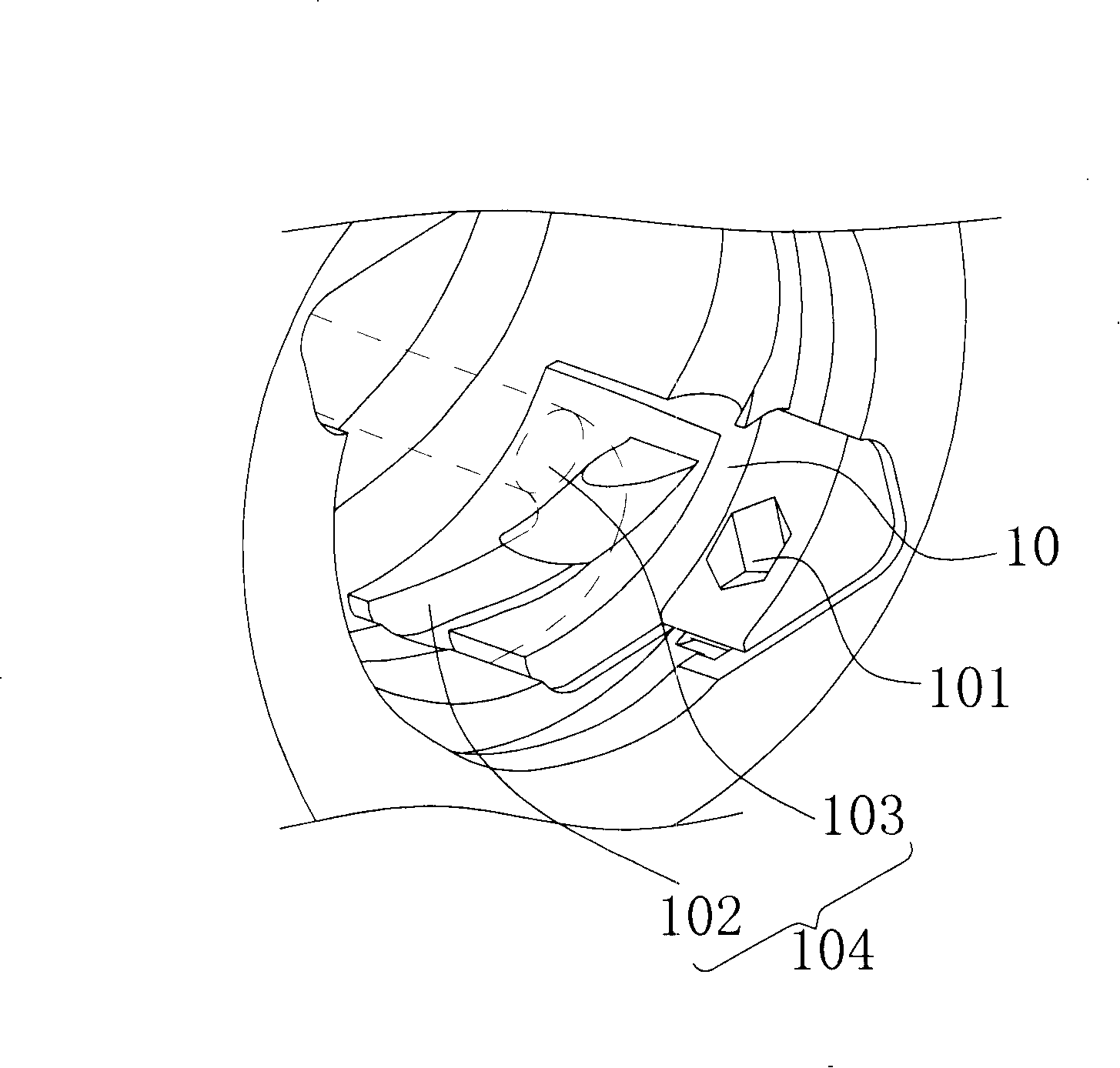

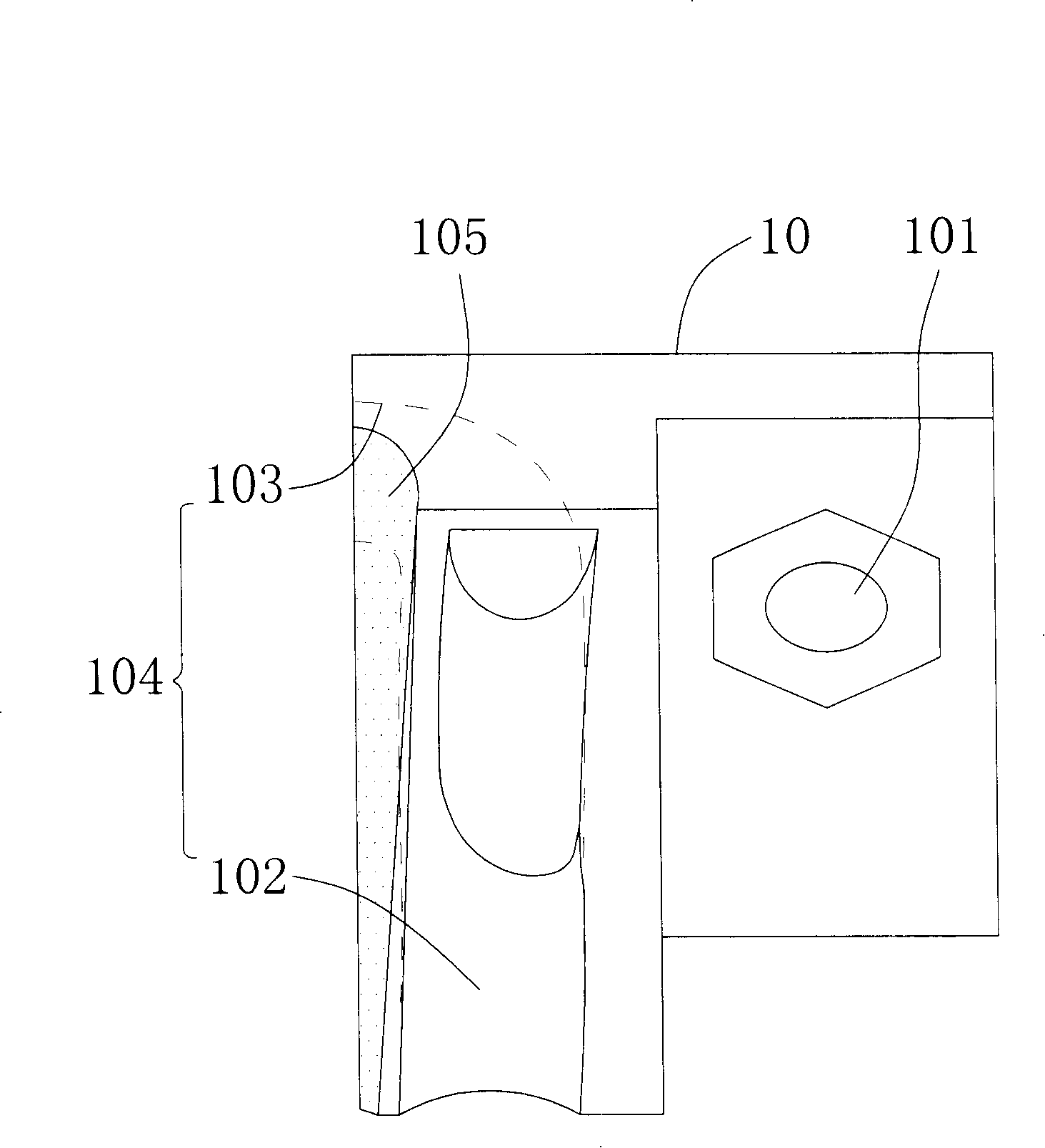

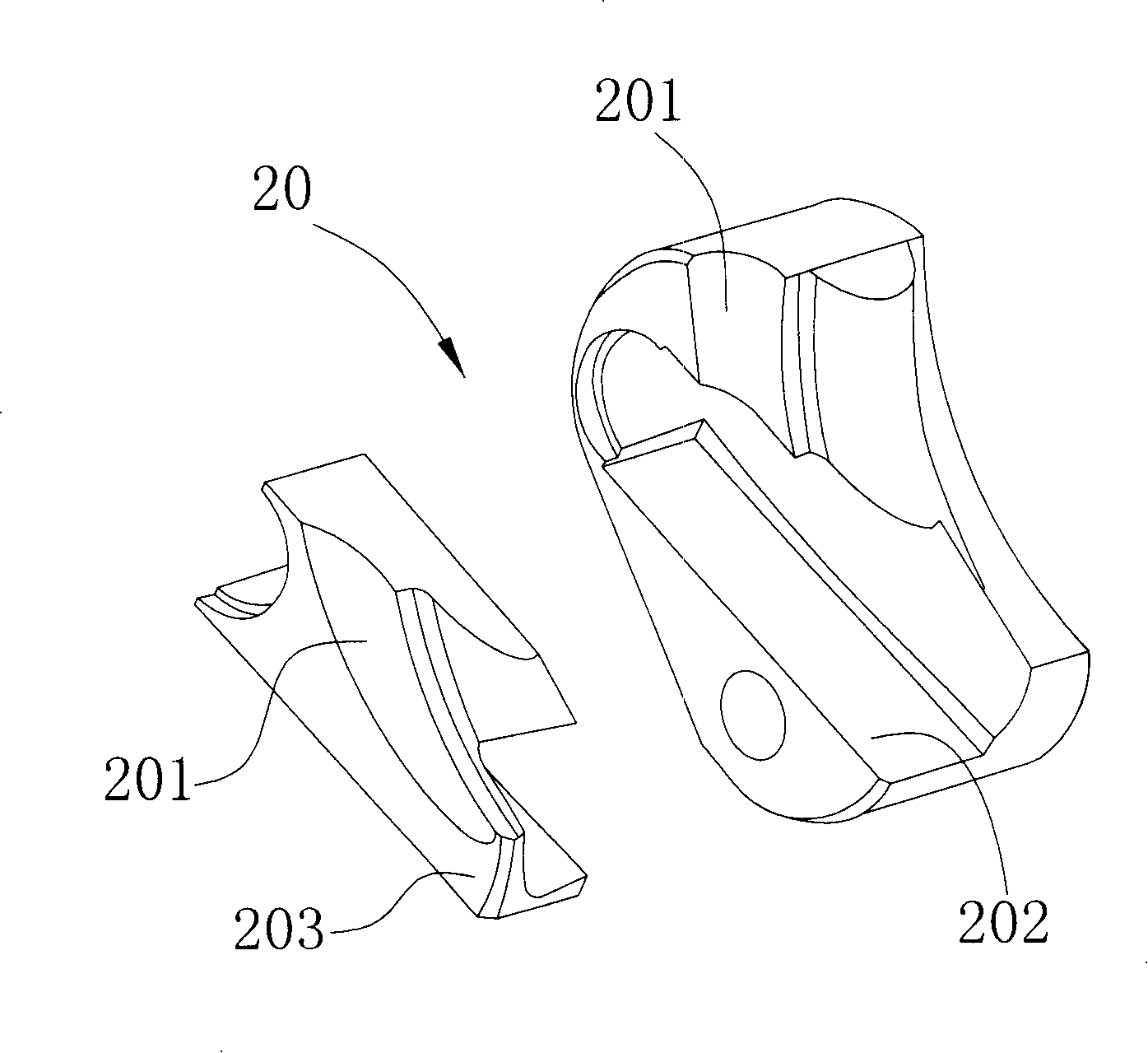

[0035] like Figure 5 to Figure 10 As shown, the return system of the ball screw of the present invention mainly includes: a screw 1, a nut 2, several return components 3 and balls 4; the outer surface of the screw 1 and the inner surface of the nut 2 have a mutual cooperation The spiral track 11, 21, and at least one through hole 22 is provided inside the nut 2, and the through hole 22 is provided with at least one fixing groove 23 on both ends of the nut 2, which is correspondingly fitted with the return component 3; The assembly 3 has a return path 31 and two openings 311, 312 inside, and the openings 311, 312 are respectively connected to the through hole 22 and the spiral track 21 of the nut 2; 11, 21 and the return flow path 31 of the return assembly 3 form an independent circulation structure that enables the balls 4 to circulate; wherein:

[0036] The fixing groove 23 of the nut 2 is axially provided with a section 24 corresponding to the return assembly 3, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com