High power semiconductor laser device reliability detection method

A laser and high-power technology, applied in semiconductor lasers, single semiconductor device testing, lasers, etc., can solve problems such as loss, reduced service life, and expensive array lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

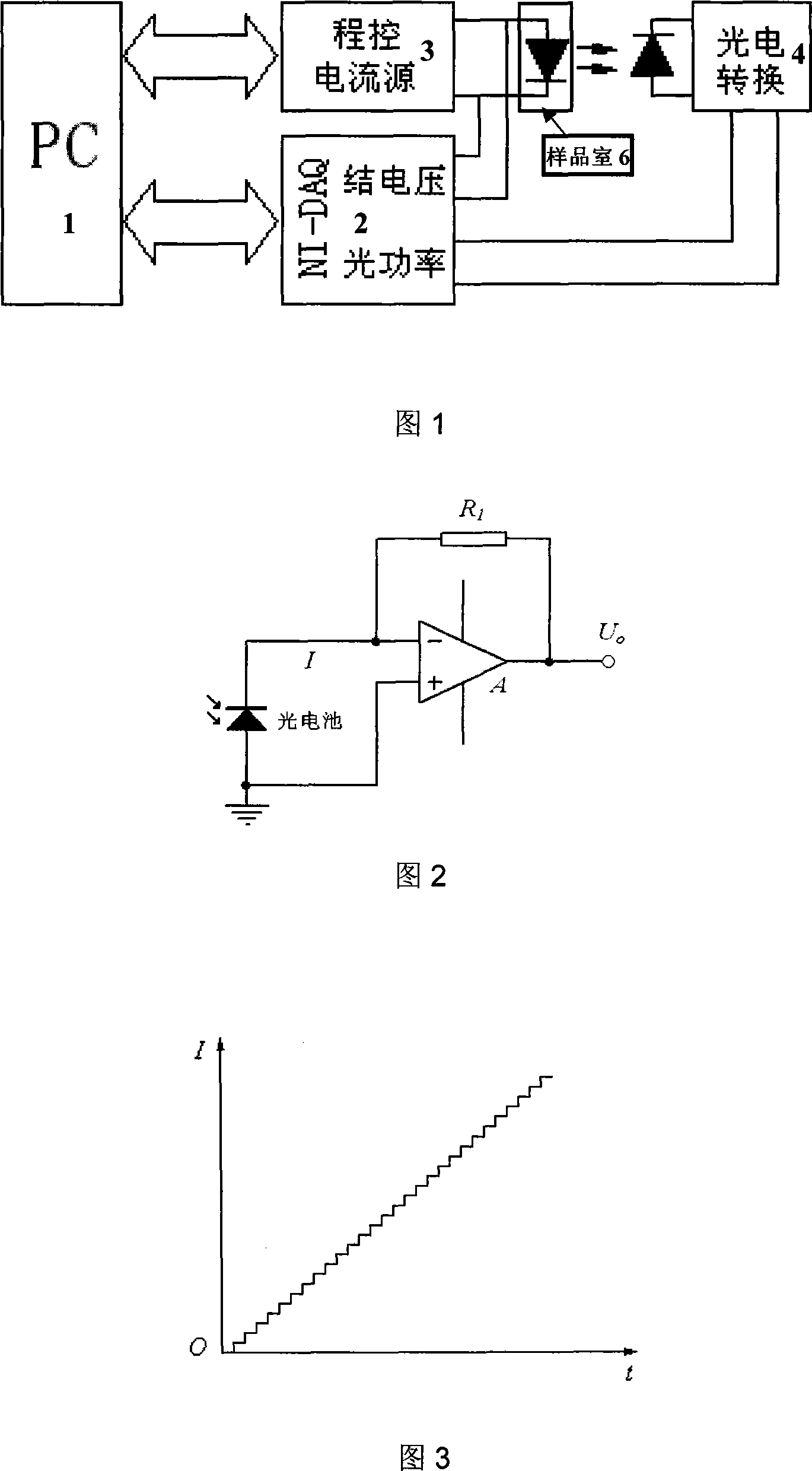

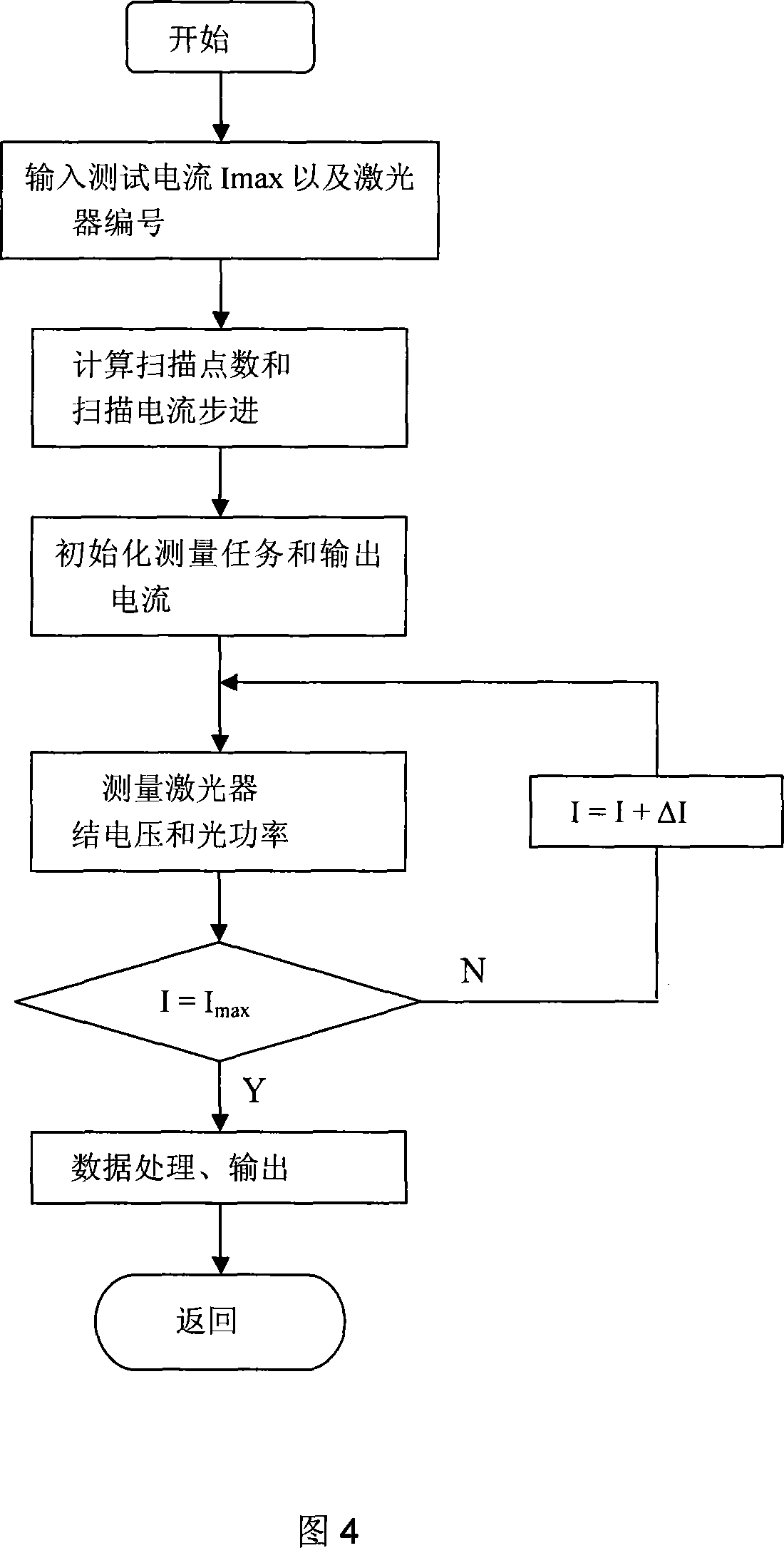

Method used

Image

Examples

Embodiment 1

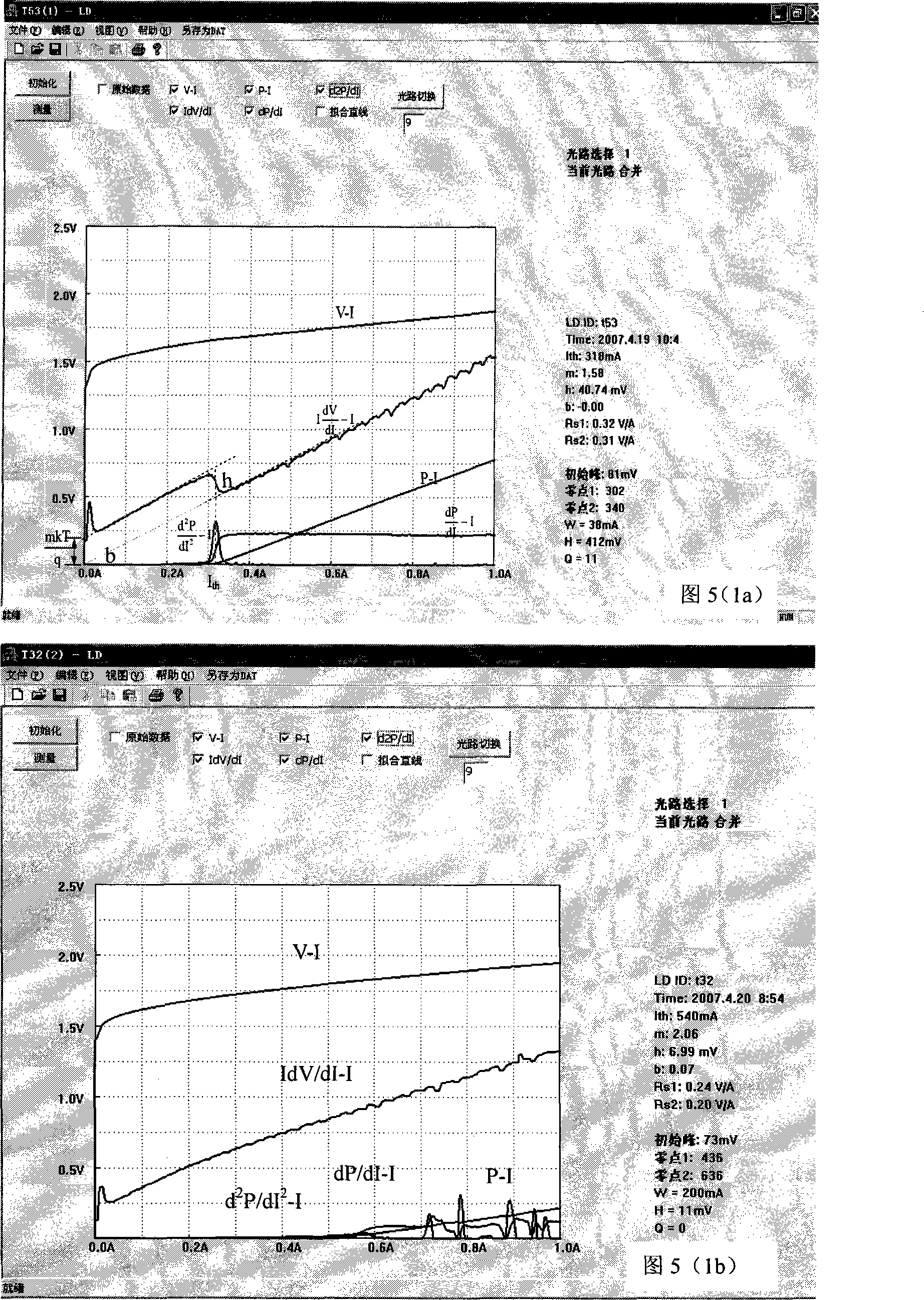

[0092] Example 1: Testing a single-tube high-power laser

[0093]The rated output optical power of the two single-tube high-power 808nm quantum well lasers manufactured by the Changchun Institute of Optics, Mechanics and Physics we measured is CW1W. Using the method described in this patent, the maximum test current value is set to 1A, the step current is 2mA, and the light derivative curve d is used. 2 P / dI 2 ~I judgment threshold, the measured curves are shown in Fig. 5(1a) and Fig. 5(1b).

[0094] The parameters they provide are shown in Table 1:

[0095] Table 1: Parameters of two single-tube high-power 808nm quantum well lasers used in this patent:

[0096] LD No.

Po(W)

Ith(A)

Io(A)

Vo(V)

Es(W / A)

Ep(%)

Rd(Ω)

t53

1.01

0.30

1.50

1.86

0.85

36

0.14

t32

0.26

0.30

1.50

1.91

0.22

9.0

0.09

[0097] Ou...

Embodiment 2

[0102] Example 2: Testing Array High Power Lasers

[0103] The rated output optical power of the two high-power 808nm quantum well array lasers we measured is CW20W, and one of them has experienced power degradation due to use for a period of time. Using the method described in this patent, the maximum test current value is set to 8A , Step current 16mA, using light derivative curve d 2 P / dI 2 ~I judgment threshold, each measured curve is shown in Fig. 5(2a) and Fig. 5(2b).

[0104] The original measurement data provided by them are shown in Table 3:

[0105] Table 3: Parameters of two high power 808nm quantum well array lasers:

[0106] LD No.

Po(W)

Ith(A)

Io(A)

Vo(V)

Es(W / A)

Ep(%)

Rd(Ω)

bz-38

21.3

4.0

25.0

1.65

1.01

51.6

6.6

031233-163

8.5

-

25.0

2.02

0.15

16.9

22.1

[0107] Our test results are shown in Table 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com