Method for designing precession cross parameter of magnetic levitation high speed rotor

A high-speed rotor and magnetic levitation technology, applied in general control systems, control/regulation systems, instruments, etc., to ensure the precession stability margin and simplify the precession cross controller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

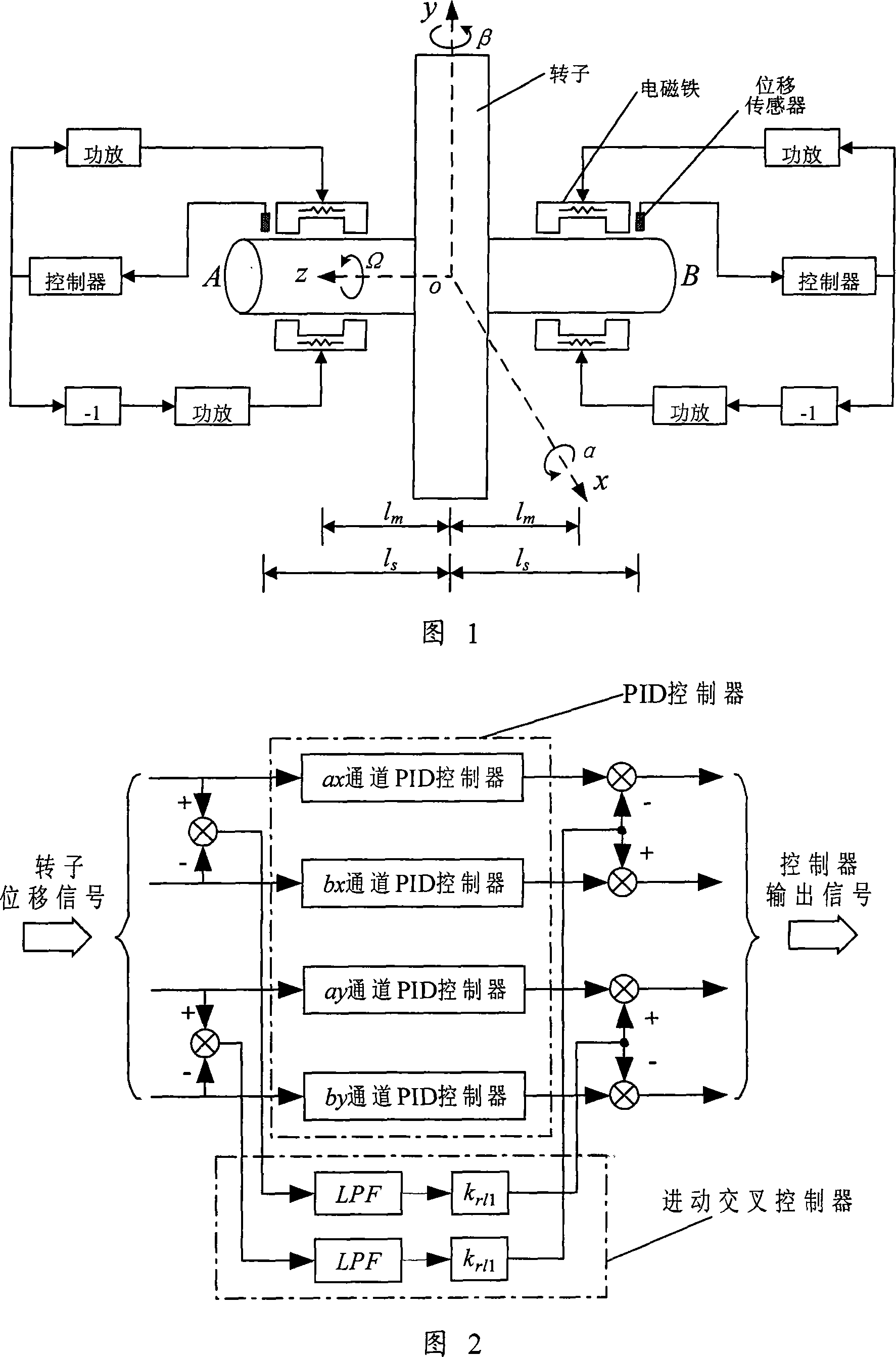

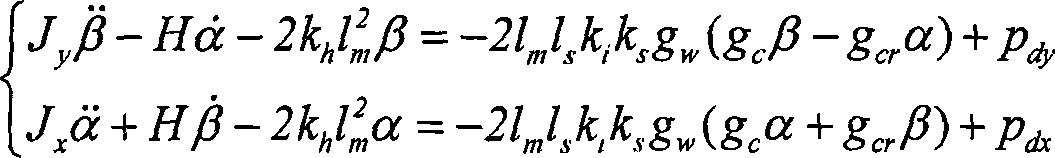

[0012] Taking a magnetic levitation rotor system as an example to illustrate the specific implementation of the method of the present invention, the design target is F rmax = Precession modal phase angle margin reaches γ at 400Hz p = 20°.

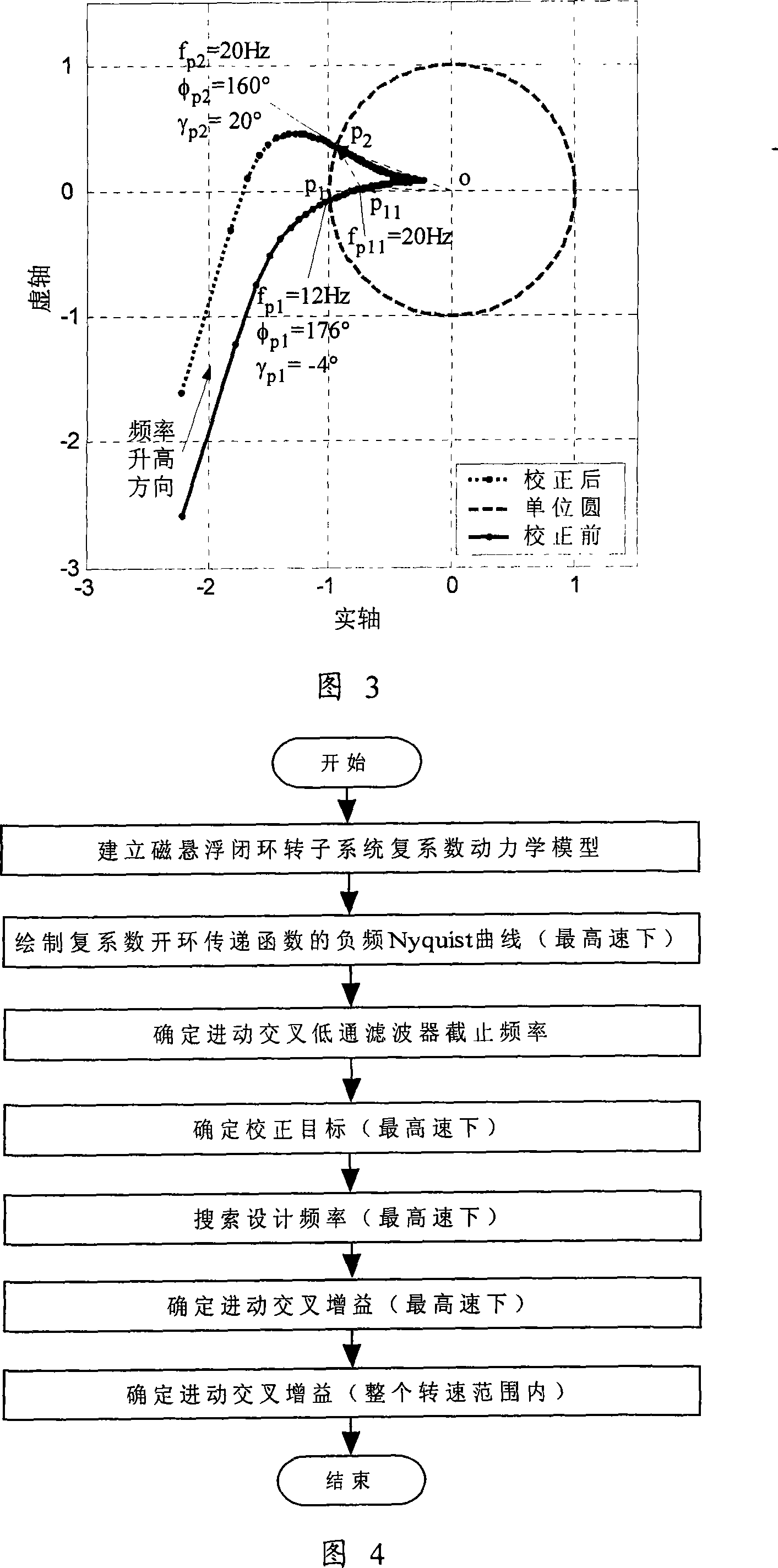

[0013] The definition of the maglev closed-loop rotor system and its coordinate system is shown in Figure 1. The system consists of a displacement sensor, a controller, a power amplifier, an electromagnet, and a rotor. oxyz is the rotor coordinate system. Point o is located at the center of mass of the rotor. To and only follow the radial rotation of the rotor without following the rotation, and the z-axis is along the axial direction of the rotor. α and β are the angular displacement of the rotor radially around the x and y axes, and Ω is the rotation speed of the rotor. In the figure, only the electromagnets in the y direction at both ends of the rotors A and B are drawn, and the x direction is similar. For each degree of freedom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com