Deterministic probabilistic safety analysis and evaluation method and system

A probabilistic safety analysis, deterministic technology, applied in the direction of probabilistic CAD, general control system, control/regulation system, etc., can solve problems such as unreliability, and achieve the effect of simplifying reliability and optimizing control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

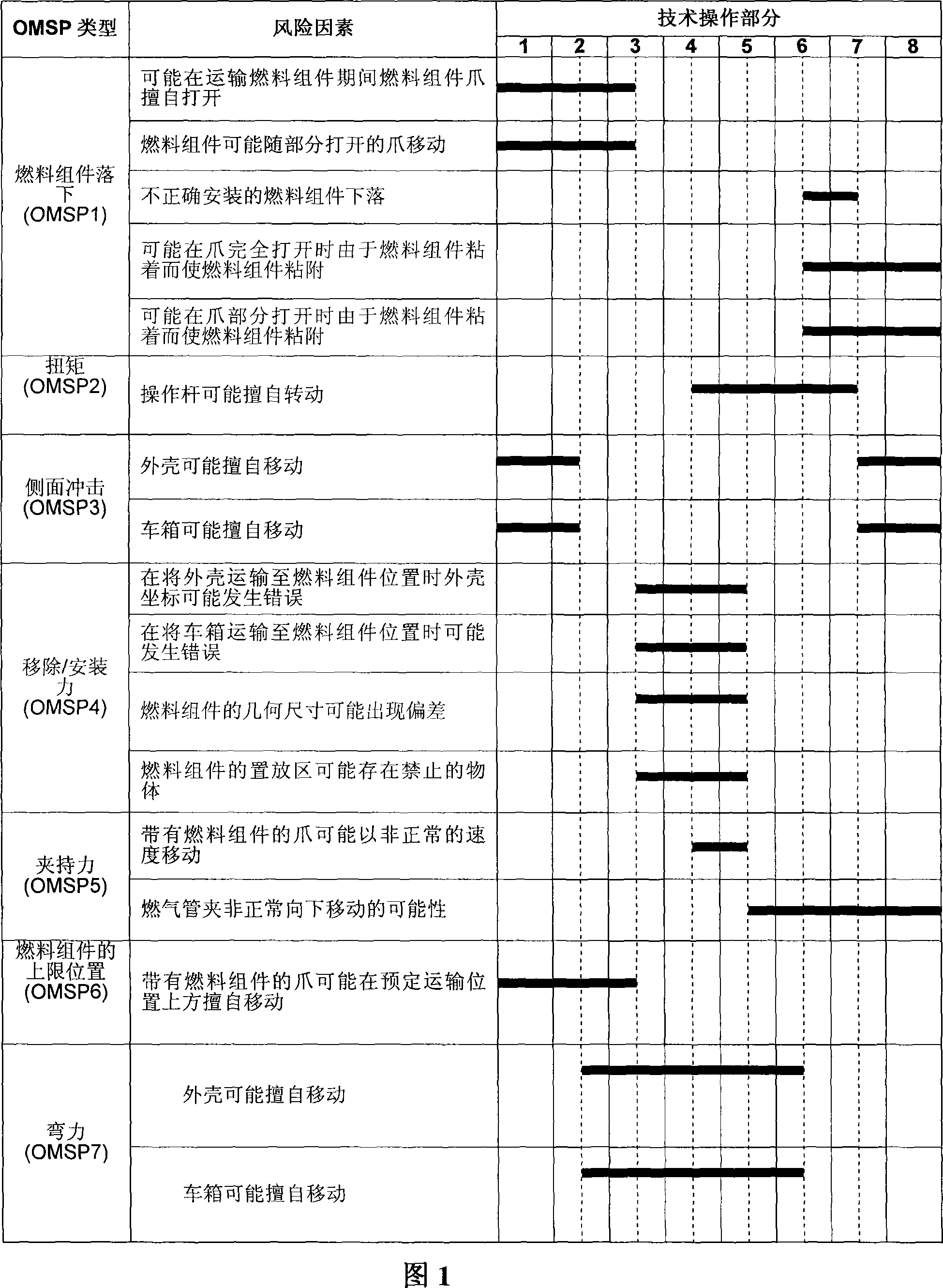

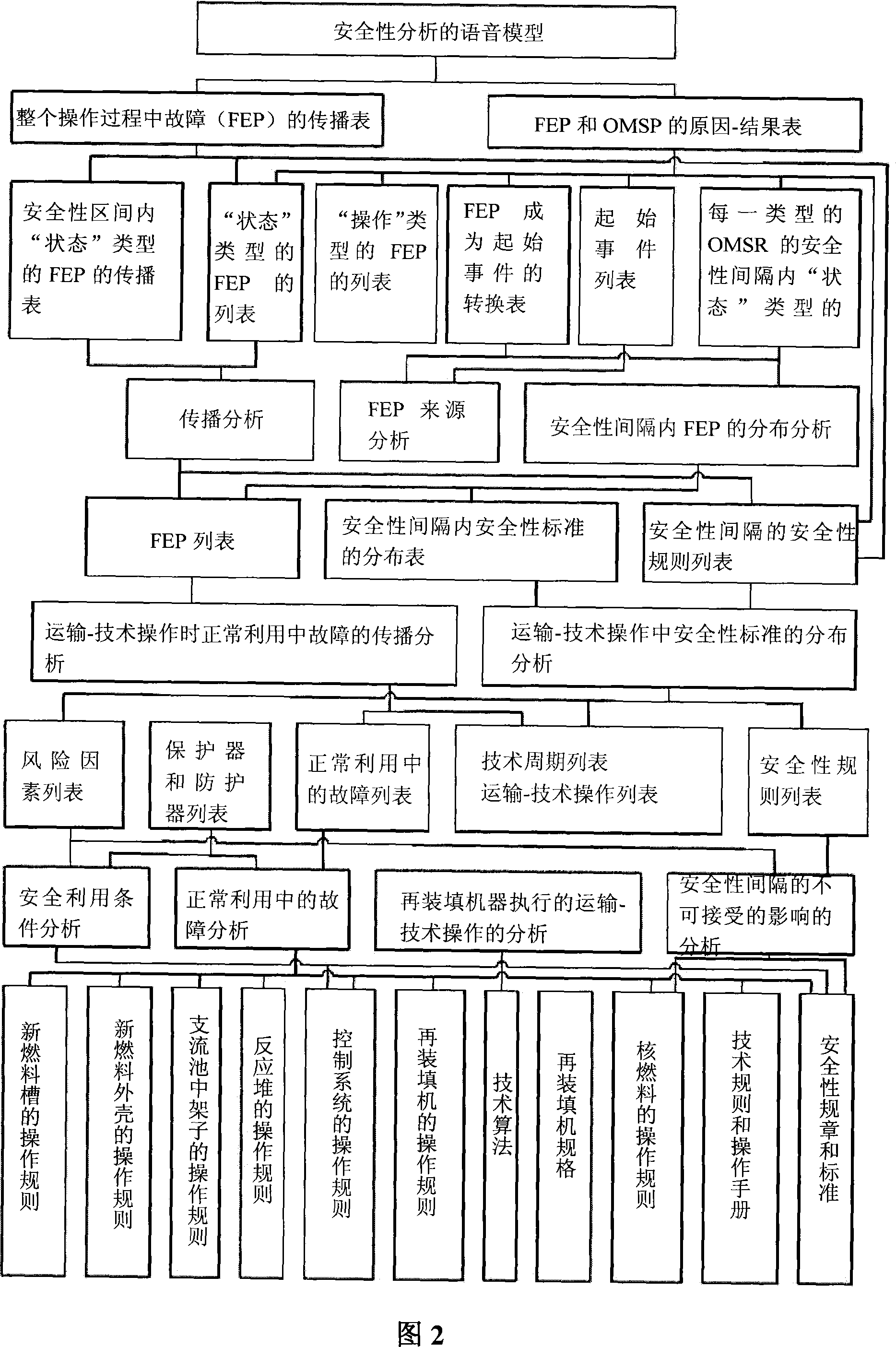

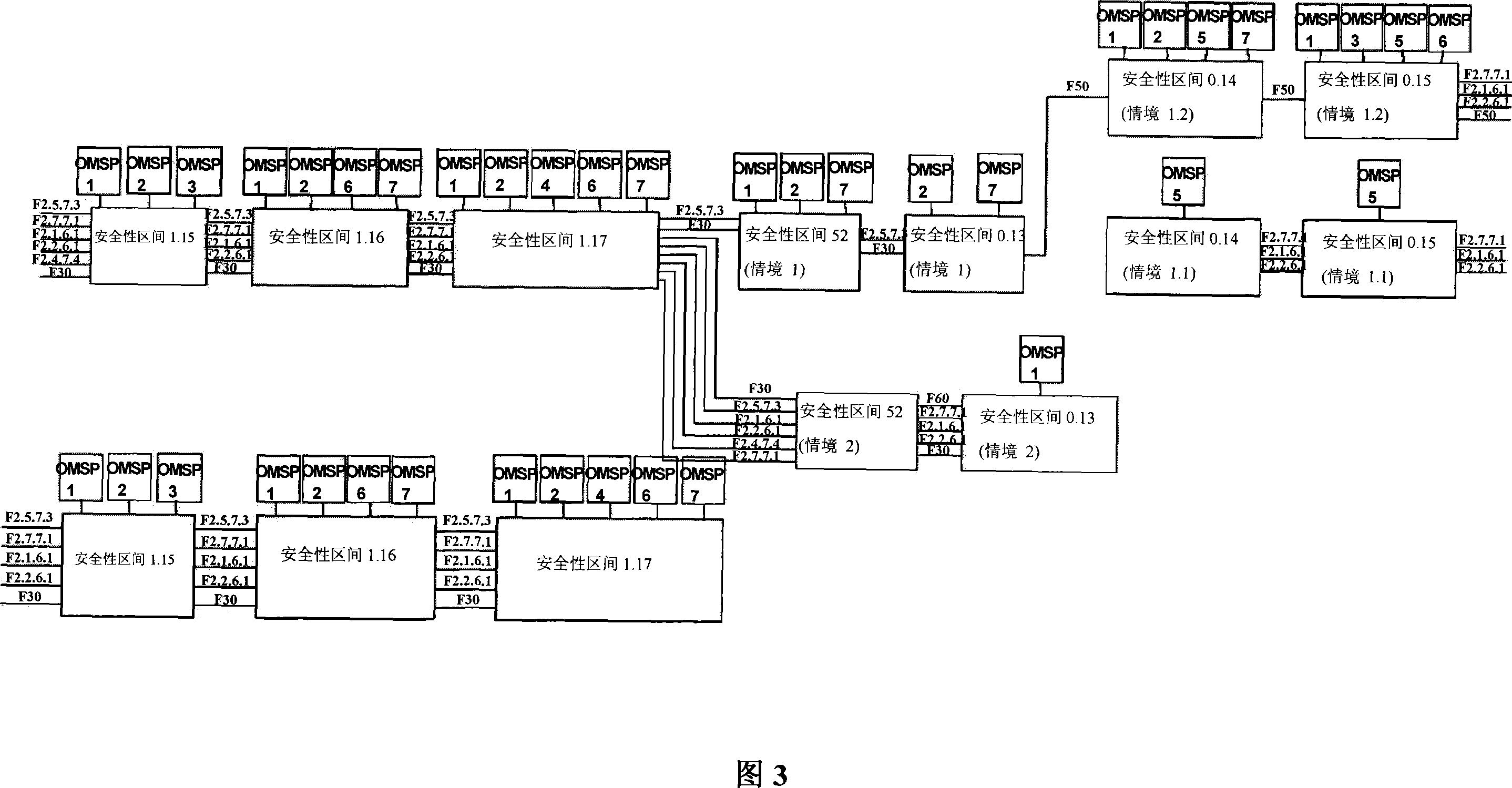

[0074] The invention is further illustrated with reference to the example of a system for safety analysis and evaluation of the handling process for refilling the core of a nuclear reactor WWER (Water / Water-Energy Reactor) designed by Russian Kurchatov Institute, Moscow.

[0075] The safety analysis of the maneuver process for refueling the core area is carried out using a system for safety analysis and evaluation of the maneuver process, the system comprising a central processing unit for performing the safety analysis and evaluation of the maneuver process, using Components for storing manipulation process data, and components for calculating probabilistic safety indices for each type of event and composite safety indices for the overall process.

[0076] Since the components of the data store contain, for example, information from references, such as process-specific safety rules, which serve as starting data for establishing lists of safety standards and limits beyond accep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com