Ultrasound wave equipment for breaking milk and removing oil

An ultrasonic and demulsification technology, applied in the field of ultrasonic demulsification and degreasing equipment, can solve the problems of liquid secondary emulsification, affecting the demulsification effect, and difficult to control the strength, so as to achieve uniform separation flow field, convenient operation and maintenance of equipment, and degreasing high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

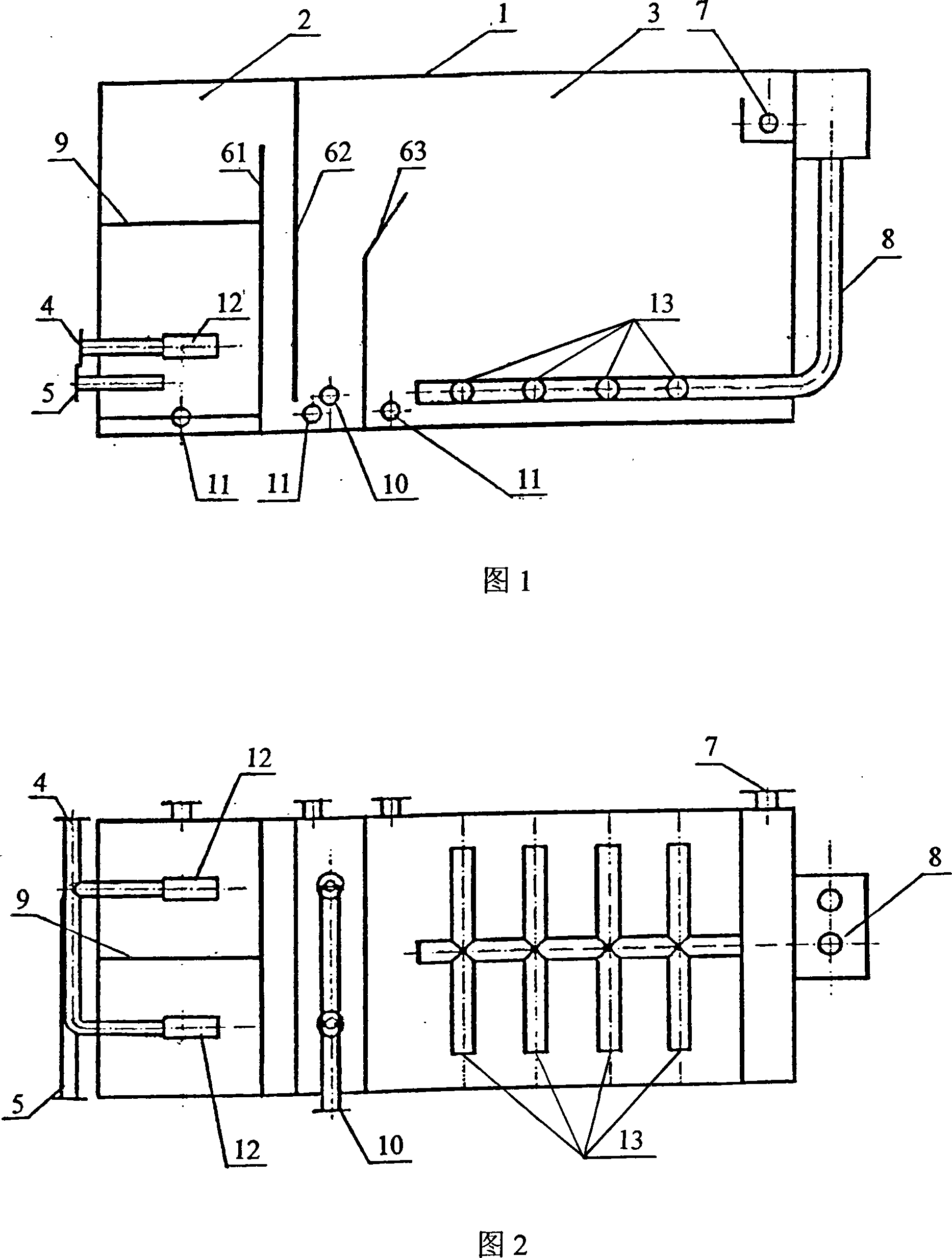

[0019] As shown in Figures 1 and 2, an ultrasonic demulsification and degreasing equipment includes a housing 1, an ultrasonic demulsification chamber 2, and an air flotation separation chamber 3. The housing 1 is provided with an air inlet pipe 4 and a water inlet pipe. 5. Dissolved air water inlet 10, water outlet pipe 8, oil outlet 7, and sewage outlet 11. The ultrasonic demulsification chamber 2 and the air flotation separation chamber 3 are separated by three partitions 61, 62, and 63. The water inlet pipe 5 enters from the lower part of the ultrasonic demulsification chamber 2, the water outlet pipe 8 is arranged at the lower part of the air flotation separation chamber 3, and the part of the water outlet pipe 8 located at the lower part of the air flotation separation chamber 3 includes a plurality of evenly distributed Water outlet 13, described ultrasonic demulsification chamber 2 is provided with two ultrasonic generators 12, and these two ultrasonic generators 12 com...

Embodiment 2

[0021] Referring to Fig. 1 and Fig. 2, an ultrasonic demulsification and degreasing equipment includes a housing 1, an ultrasonic demulsification chamber 2, and an air flotation separation chamber 3. The housing 1 is provided with an air inlet pipe 4, a water inlet pipe 5, Dissolved air water inlet 10, water outlet pipe 8, oil outlet 7, and sewage outlet 11. The ultrasonic demulsification chamber 2 and the air flotation separation chamber 3 are separated by three partitions 61, 62, 63. The inlet The water pipe 5 leads into the lower part of the ultrasonic demulsification chamber 2, the water outlet pipe 8 is arranged at the lower part of the air flotation separation chamber 3, and the part of the water outlet pipe 8 located at the lower part of the air flotation separation chamber 3 includes a plurality of evenly distributed water outlets 13. The ultrasonic demulsification chamber 2 is provided with two ultrasonic generators 12, the two ultrasonic generators 12 include oscillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com