Random working angle precision electrolytic machining method and machine tool

An electrolytic machining machine tool, working angle technology, applied in electrochemical machining equipment, metal machining mechanical parts, metal machining equipment, etc., to achieve the effect of good operating space, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

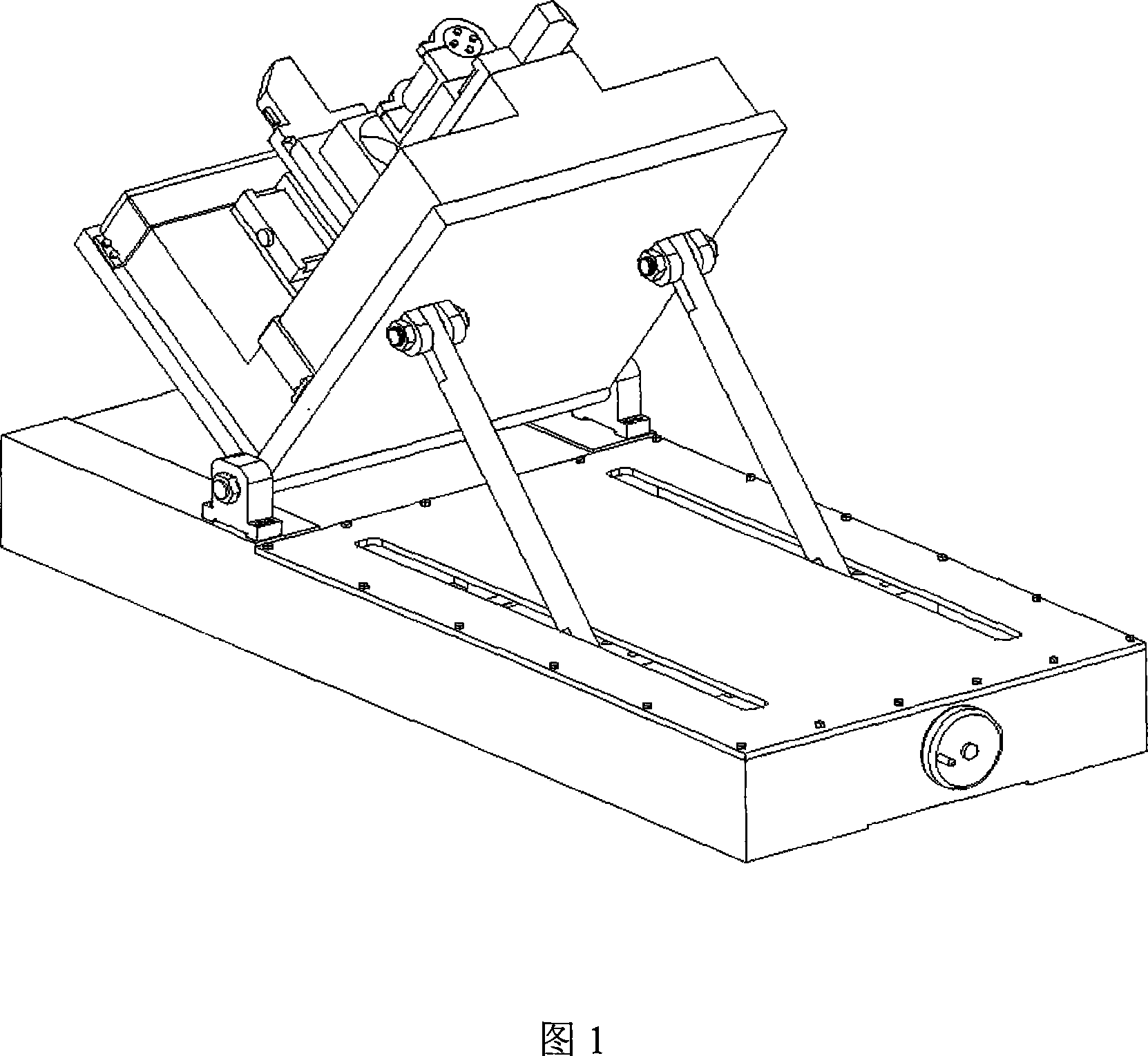

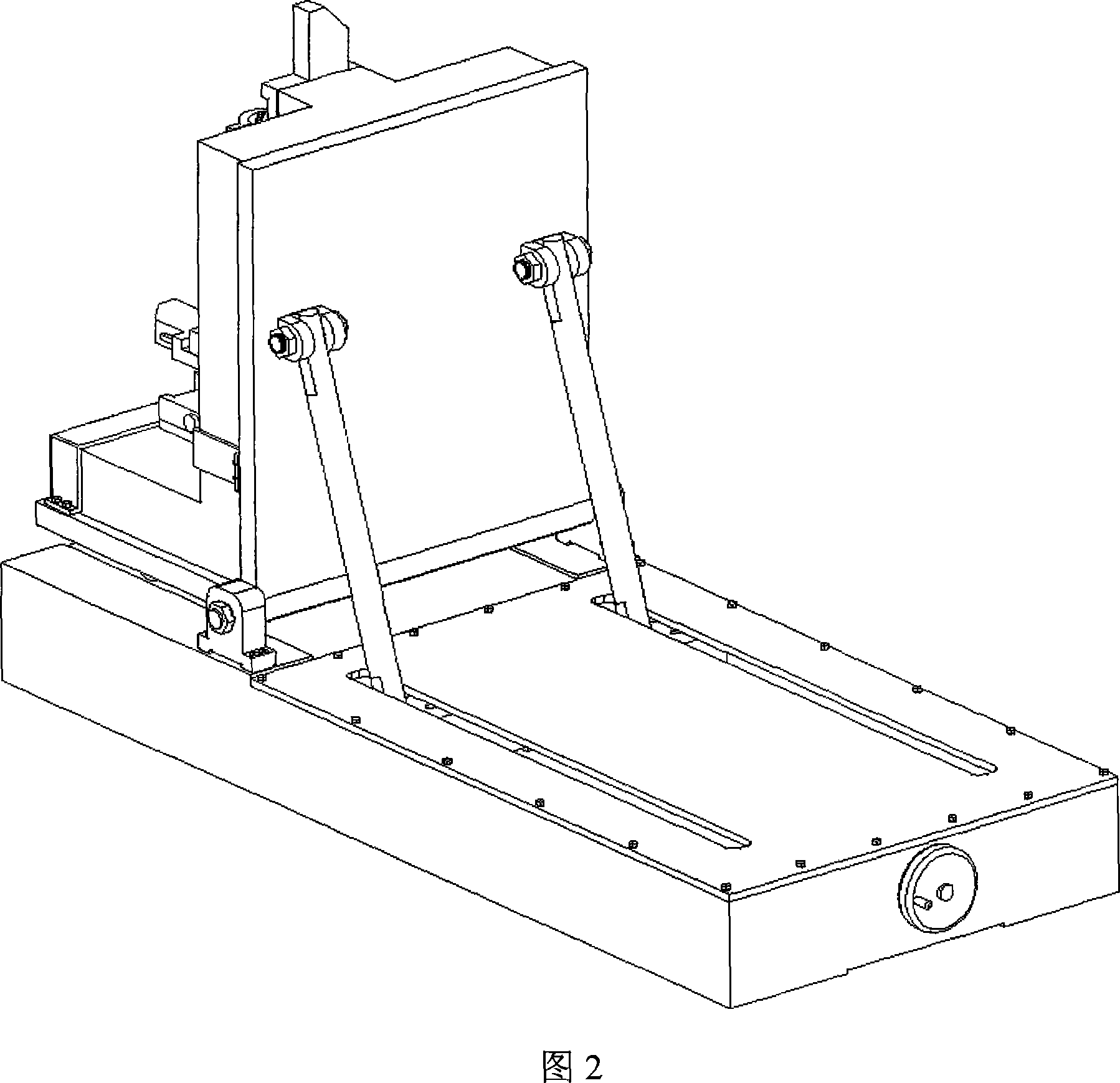

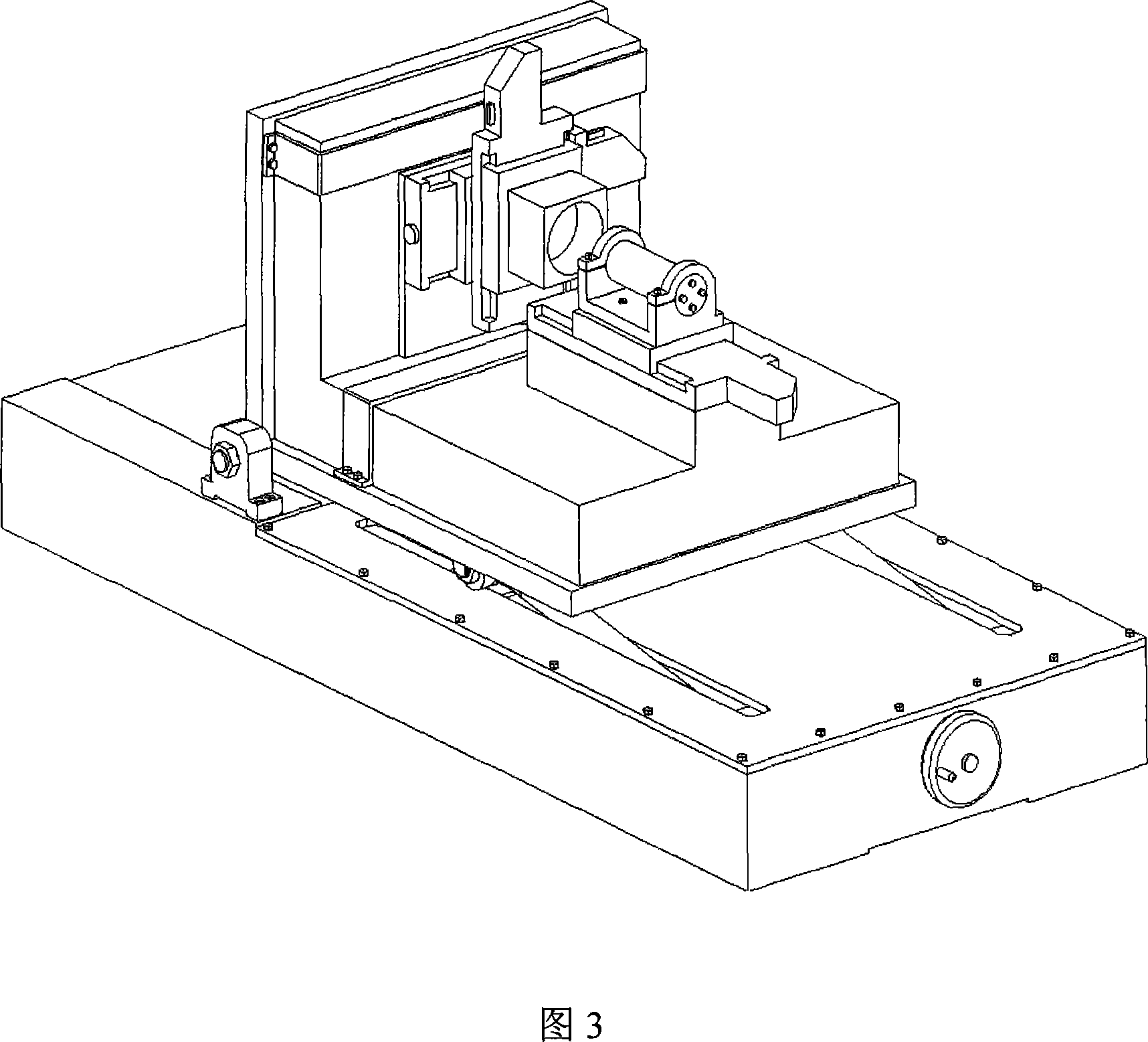

[0019] The present invention—arbitrary angle adjustable precision electrolytic machining machine tool, as shown in Figure 6, includes x workbench 1, y workbench 2, work box 3, spindle and its lead-in device 13, z workbench 5, bed 6 , Angle adjustment device 7. The high-speed spindle is installed on the z workbench, and the axis is perpendicular to the x and y workbenches; the working box is installed on the y workbench, and the y workbench is installed on the x workbench. During the machining process, the tool electrode installed on the high-speed spindle is perpendicular to the workpiece; the bed is installed on the angle adjustment device.

[0020] When using different processing techniques, choose different machine tool layouts, vertical, horizontal or a suitable processing posture between vertical and horizontal, to ensure the timely update of the electrolyte and the timely removal of electrolytic products.

[0021] Because the tool electrode is installed on the high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com