Transport unit for producing the sanitary equipment

A technology of transmission device and conveying device, which is applied in the direction of hoisting device, transportation and packaging, portable lifting device, etc., to save manpower, prevent damage, and save storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

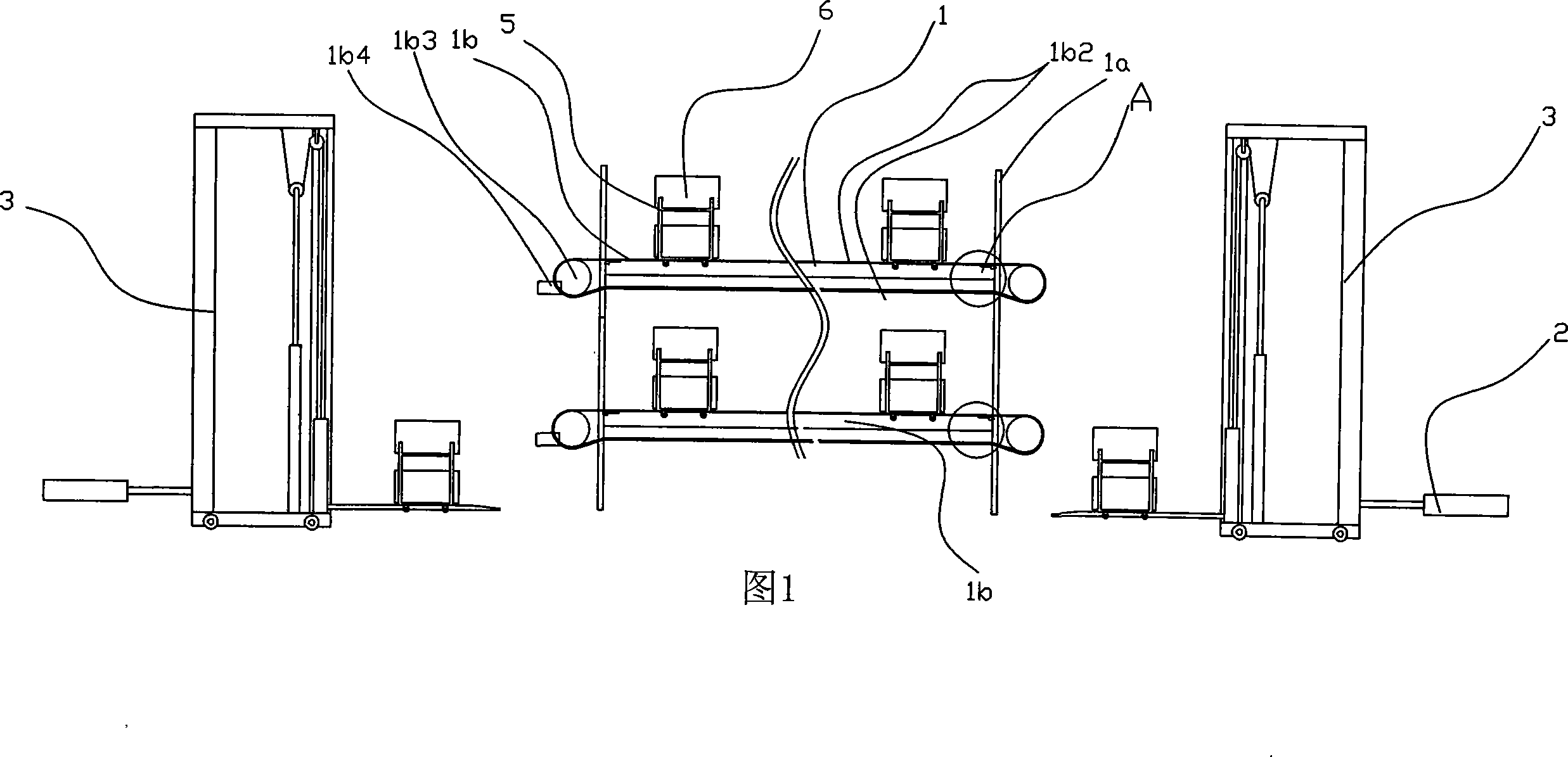

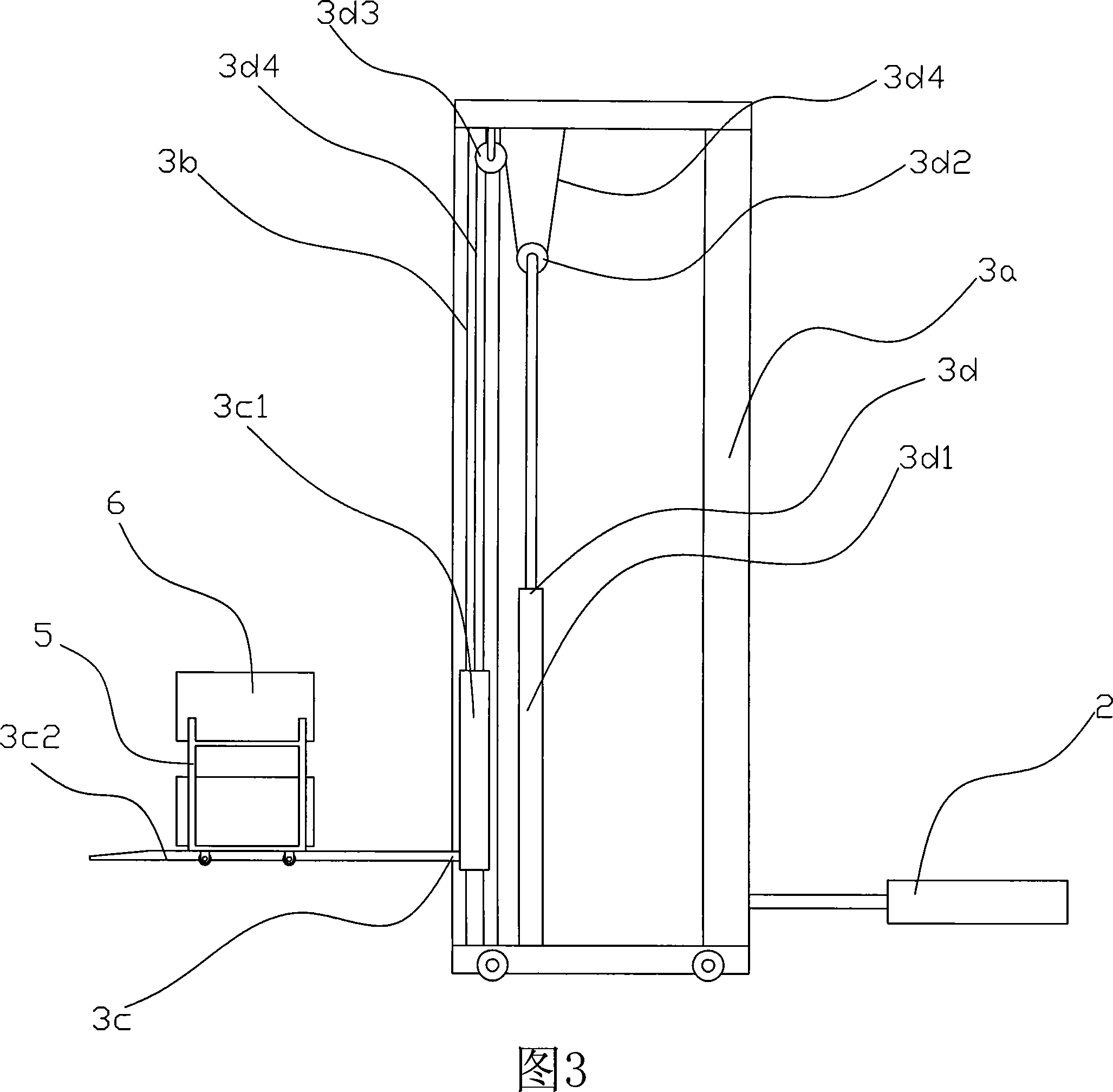

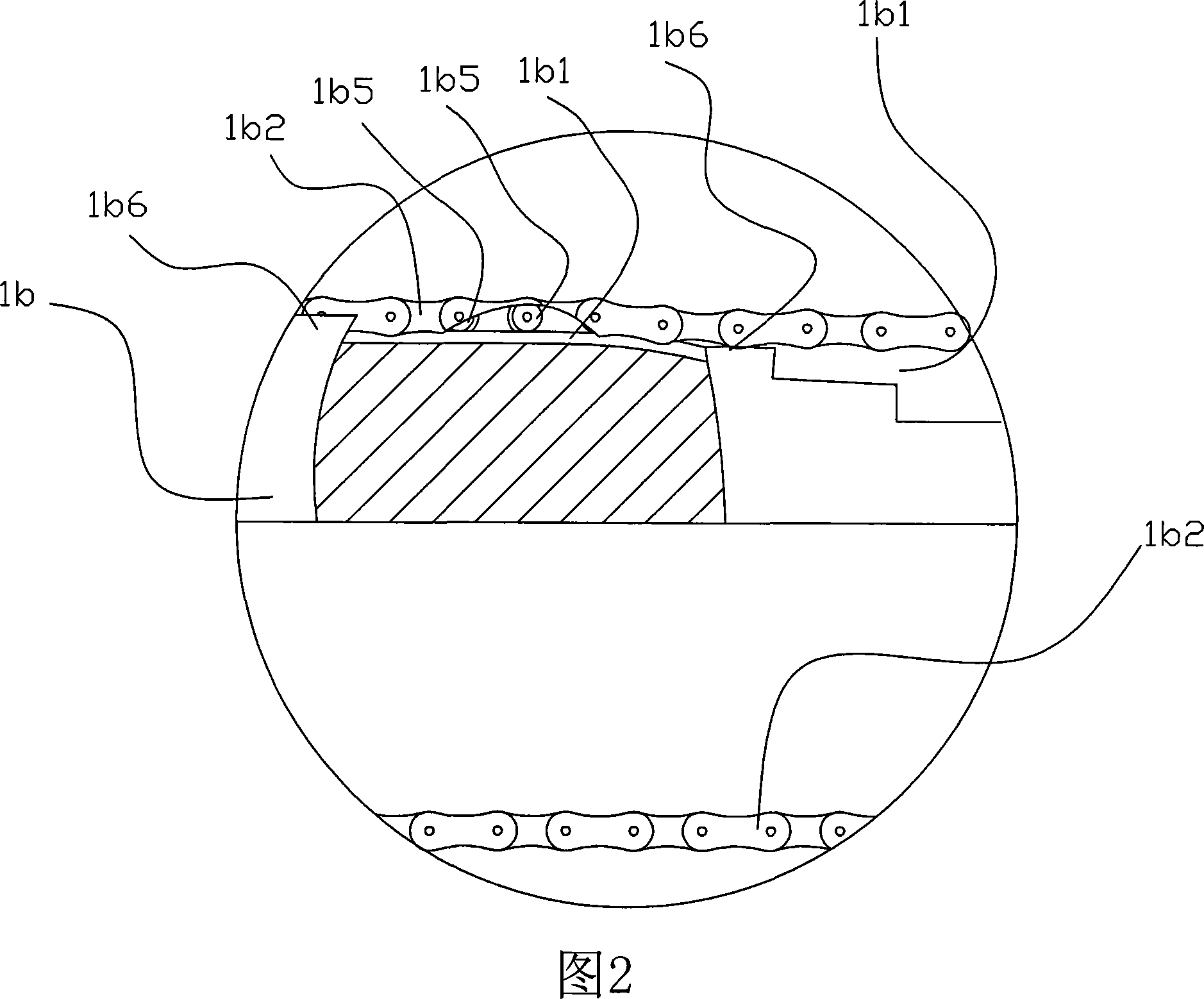

[0015] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0016] The production process of the sanitary ware of the present invention is realized in this way, including the grouting molding process, the drying process, the crack detection process, the glazing process, and the firing process in sequence. The special feature is that the sanitary ware body is first placed in the drying process On the trolley, place the trolley in sequence through the lifting device on two or more layers of conveyor belts connecting the grouting molding process and the crack detection process. After the inspection process, the trolley and the sanitary ware body on the trolley are removed from the conveyor belt by the lifting device, and then crack detection is performed on the sanitary ware body on the trolley in the crack detection process, and the trolley and the sanitary ware body on the trolley are The time of transmission on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com