Wine brewing technique of distilled wine

A technology of distilling wine and craftsmanship, which is applied in the field of wine making, and can solve the problem that distiller's grains have no use value in the breeding industry, and achieve the effects of reducing the price of pork, saving manpower, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

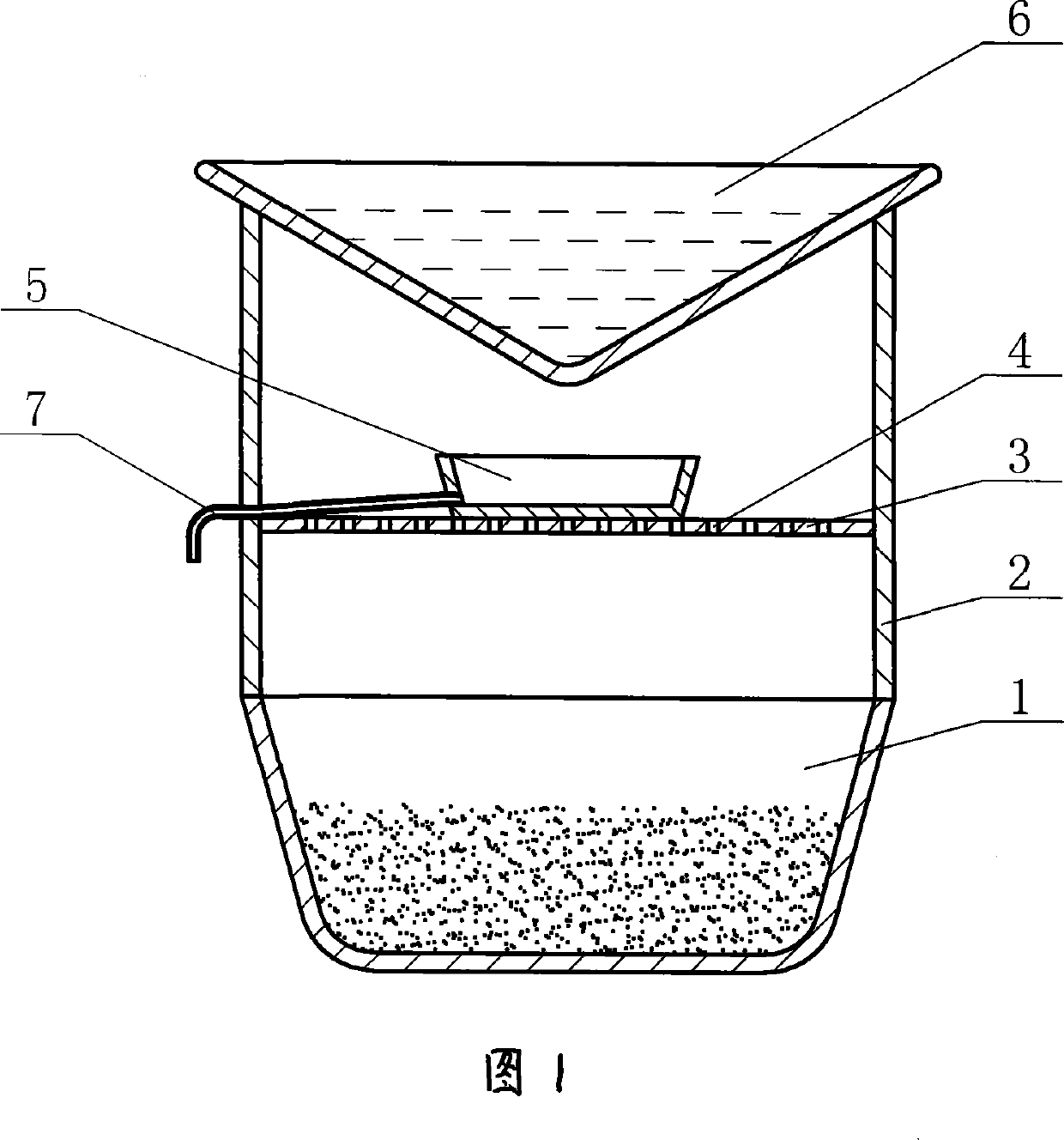

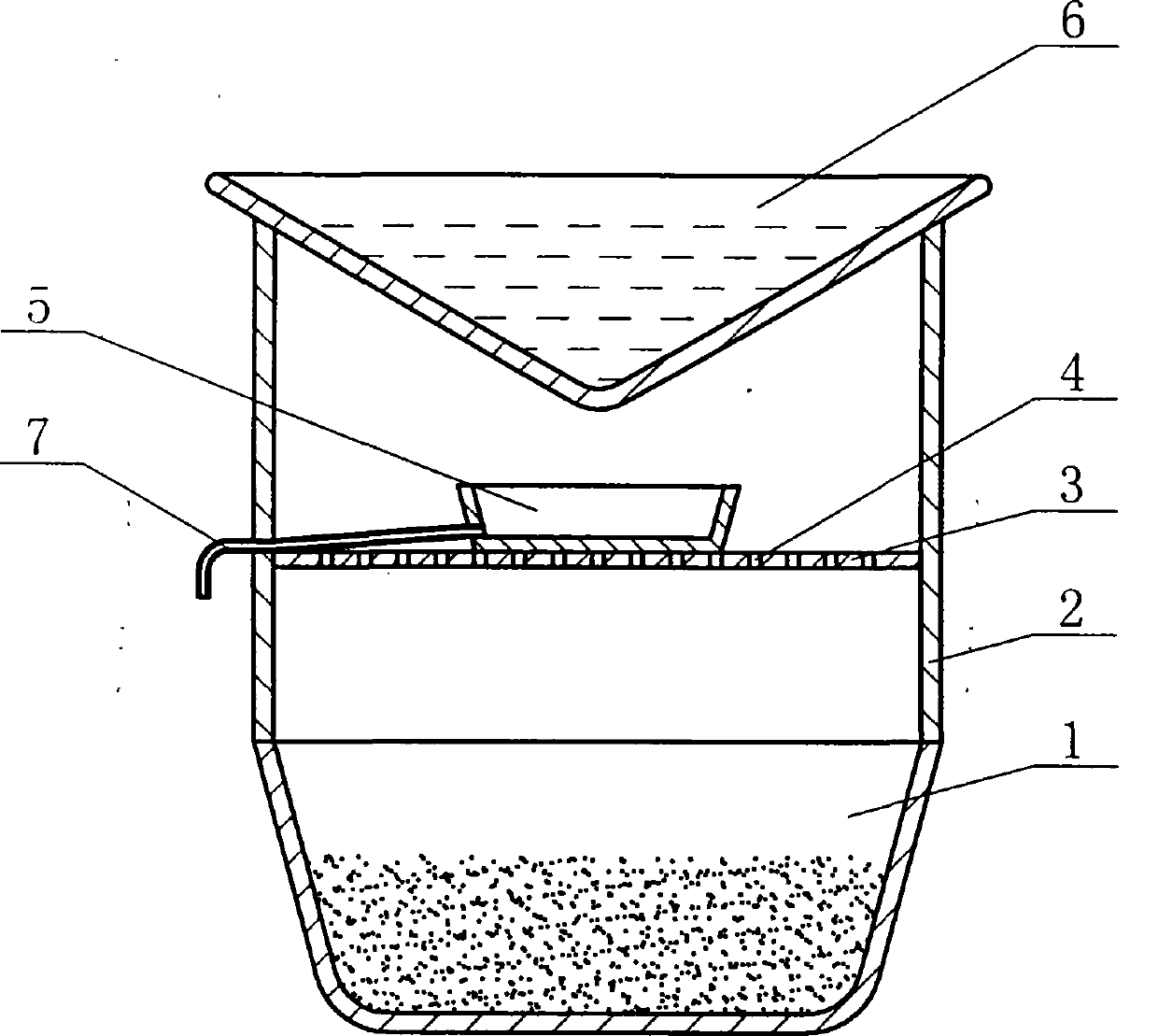

[0012] The brewing equipment of the present invention has a first container 1, the open outer edge of the upper end of the first container 1 is connected with the bottom end of the cylindrical body 2, the upper end of the cylindrical body 2 is connected with the outer wall of the bottom of the second container 6, and the inner wall of the middle part of the cylindrical body 2 is installed Air-permeable plate 3 is arranged on the air-permeable plate 3 and connects the wine tray 5, and offers holes on the wine tray 5, and the holes are connected with the pipeline 7. The bottom of the second container 6 is V-shaped to facilitate the wine liquid to flow into the wine tray 5 . Ventilation plate 3 is provided with ventilation hole 4, and the diameter of ventilation hole 4 is 0.12-0.16 millimeter, so that steam slowly rises and permeates fragrant grains, thereby reaching the purpose of increasing wine fragrance.

[0013] The wine-making process of the present invention is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com