Mechanical defoaming device

A defoamer and mechanical technology, which is applied in the direction of paper machine, paper machine wet end, textile and paper making, etc., can solve the problems of long-term idle use, etc., and achieve the effect of reliable operation, easy operation and maintenance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

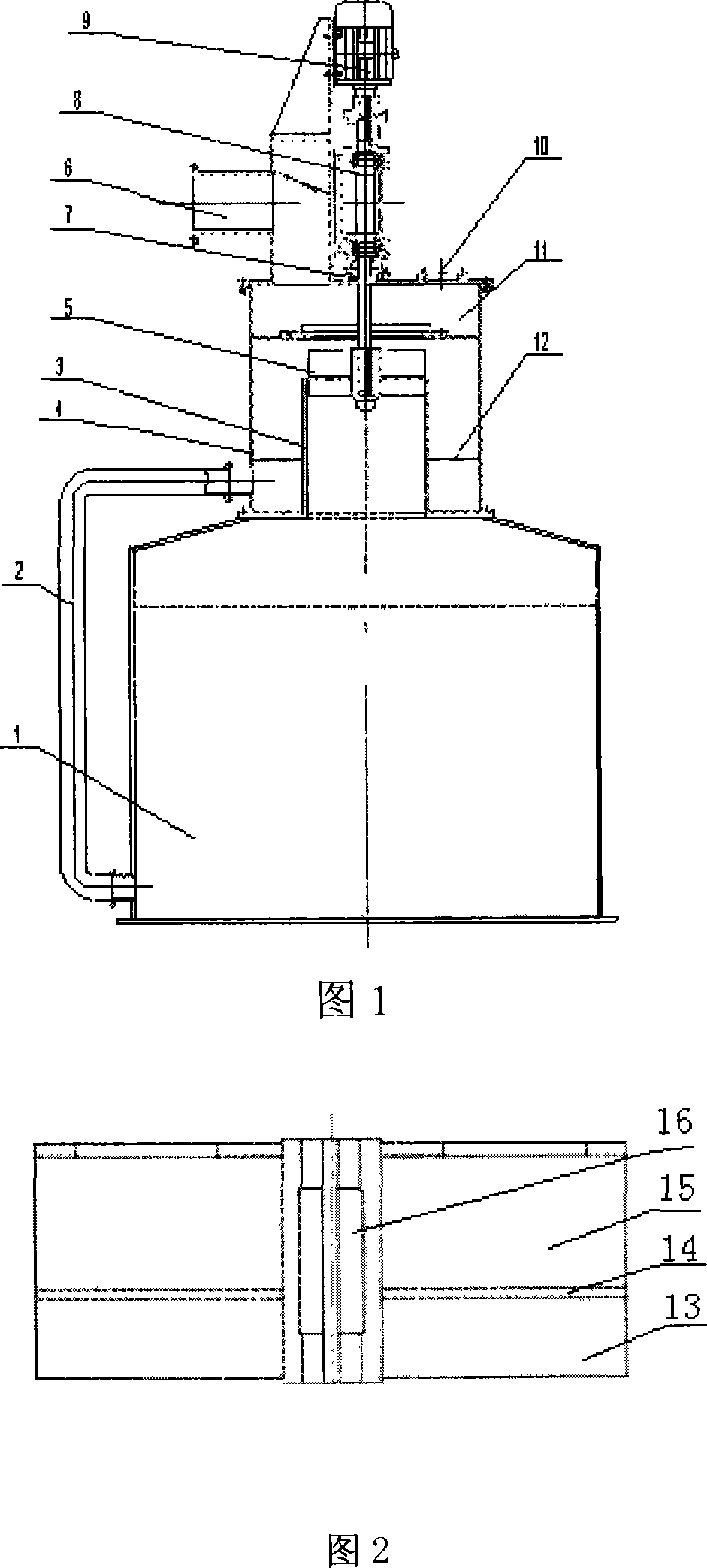

[0013] Below according to accompanying drawing and specific embodiment the present invention is further described as follows:

[0014] As can be seen from Fig. 1, the mechanical defoamer of the present invention includes a motor 9, a main shaft 8, an impeller 5, and an exhaust port 6, and is placed on the foam collection tank 1, forming a combination with the foam collection tank 1, and the suction of the defoamer The mouth is a vertical diversion inner cylinder 3, its diameter can contain the impeller 5, and the diversion inner cylinder outside is the diversion outer cylinder 4 that constitutes the housing of the defoamer. A trapping chamber 12 is formed between the flow-guiding inner cylinder 3 and the flow-guiding outer cylinder 4 . An expansion chamber 11 is provided on the guide outer cylinder 4 . There is a discharge port on the diversion outer cylinder 3, which is connected with the foam collection tank 1 through the return pipe 2. As can be seen from Fig. 2, the impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com