Automatic control spraying and sprinkling system

A technology of spraying system and spraying device, applied in the direction of water spray cooler, direct contact heat exchanger, heat exchanger type, etc., which can solve the problems of poor vacuum maintaining ability, poor safety performance, and prone to vibration of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

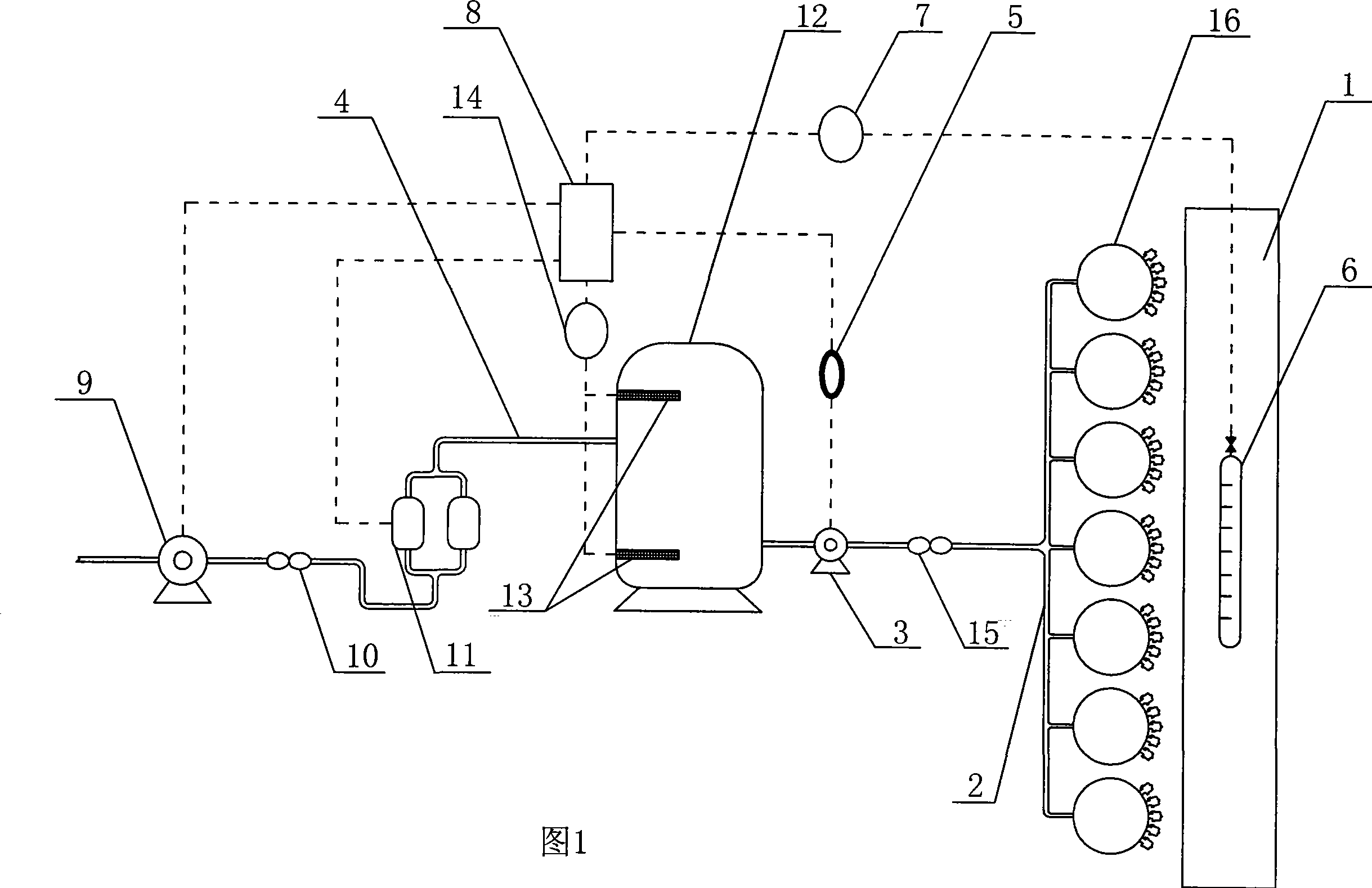

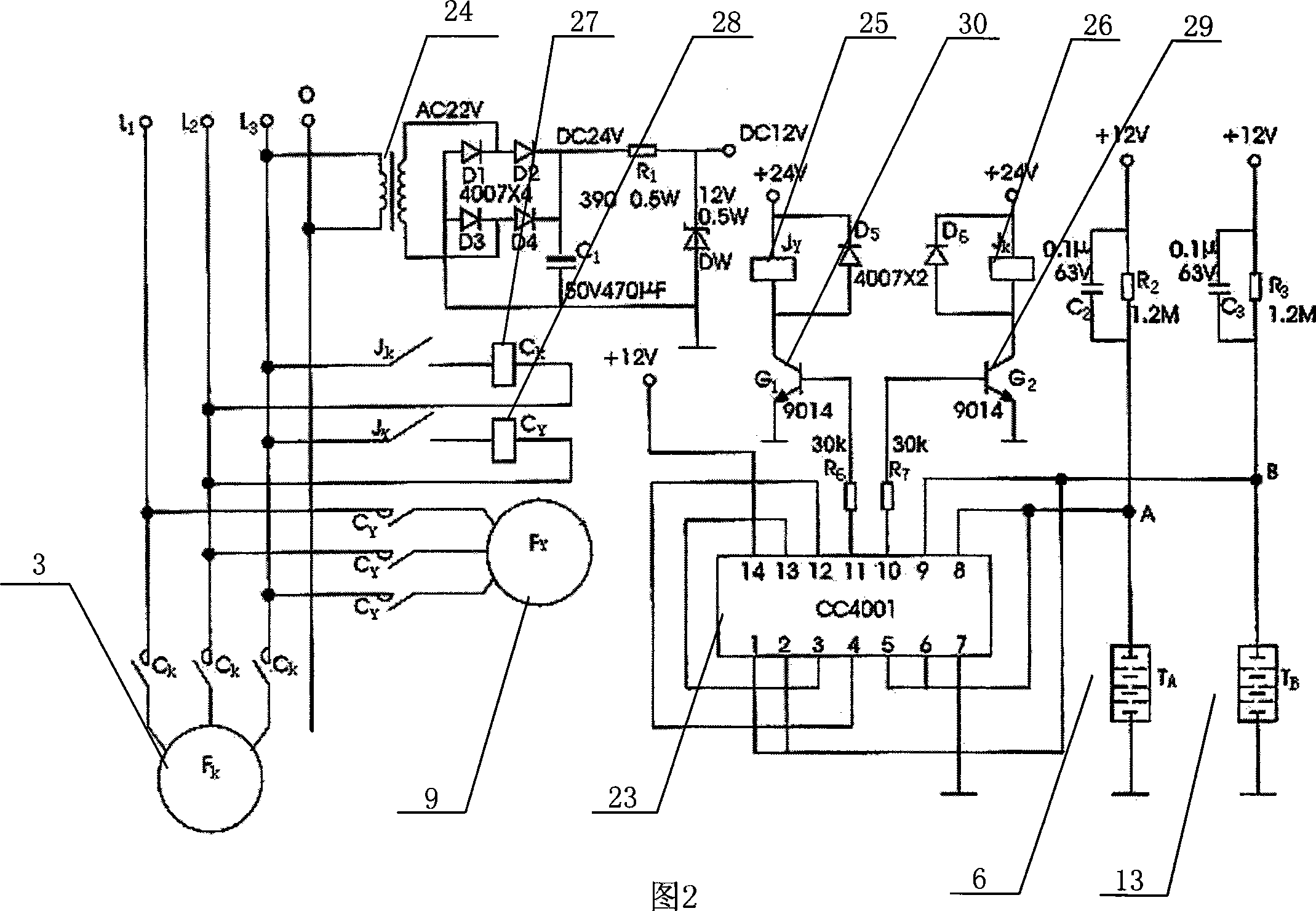

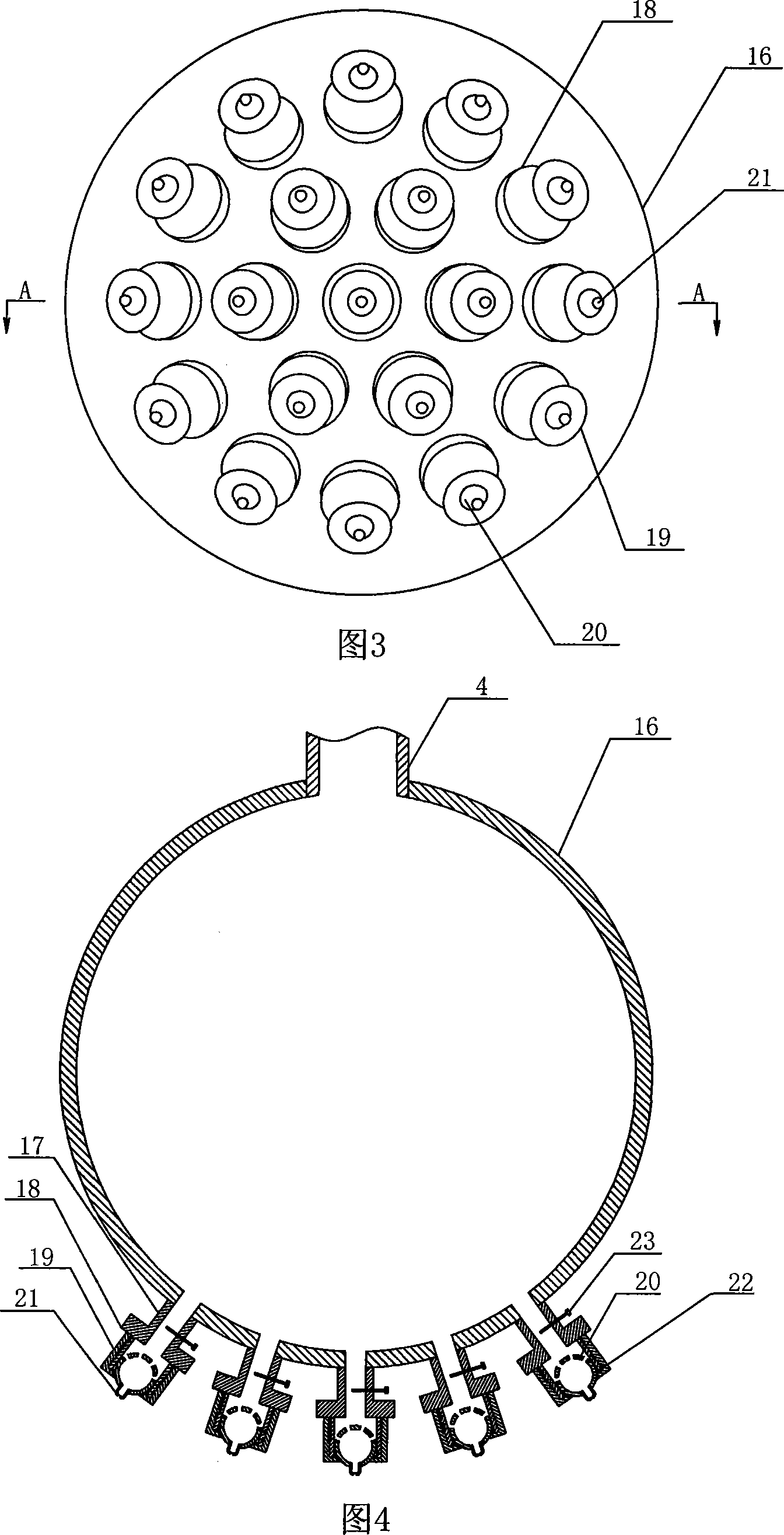

[0015] As shown in Fig. 1, Fig. 3, Fig. 4 and Fig. 5, the automatic control spraying system of the present invention includes a spraying device 2 for spraying the heat exchange unit 1, and the spraying device 2 is provided with a water spray pump 3 The water delivery pipeline 4 communicates with the water purification system, the water spray pump 3 is electrically connected to the frequency converter 5, a temperature sensor 6 is arranged on the surface of the heat exchange unit 1, the temperature sensor 6 is electrically connected to the signal sensor 7, and the frequency converter 5 And signal sensor 7 is electrically connected with signal processor 8 respectively; Described water purification system is made up of water pump 9, filter 10, water purification device 11 and water storage tank 12 that are connected successively by water delivery pipeline 4, and in water storage tank 12 A water level sensor 13 is provided, and the water level sensor 13 is electrically connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com