Ultra-precise cutting knife selection method

A turning tool, ultra-precision technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of reducing the machining accuracy of machine tools, damage to the shape of the workpiece, damage to the diamond tool, etc., to avoid the effect of machining interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

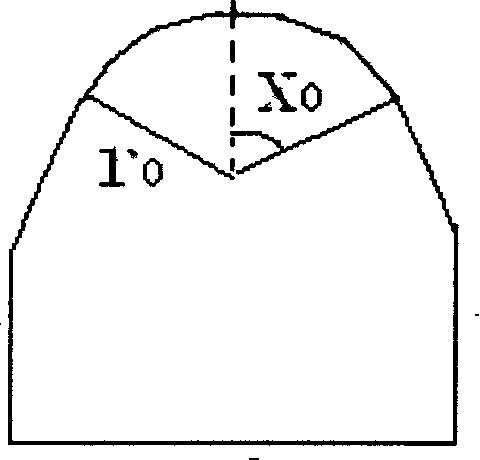

[0028] Single point diamond tool cutting surface such as figure 1 As shown, the parameter on the cutting surface is the radius of the tool nose arc r 0 , tool nose arc radian x 0 . The machined surface topography of diamond ultra-precision turning itself contains features defined by these two parameters. The radian of the tool nose is limited by the curvature characteristics of the processing surface; the radius of the tool nose arc is limited by the characteristics of the concave area of the processing surface. If the radius of the concave area is too small relative to the radius of the arc, there is a possibility of machining interference.

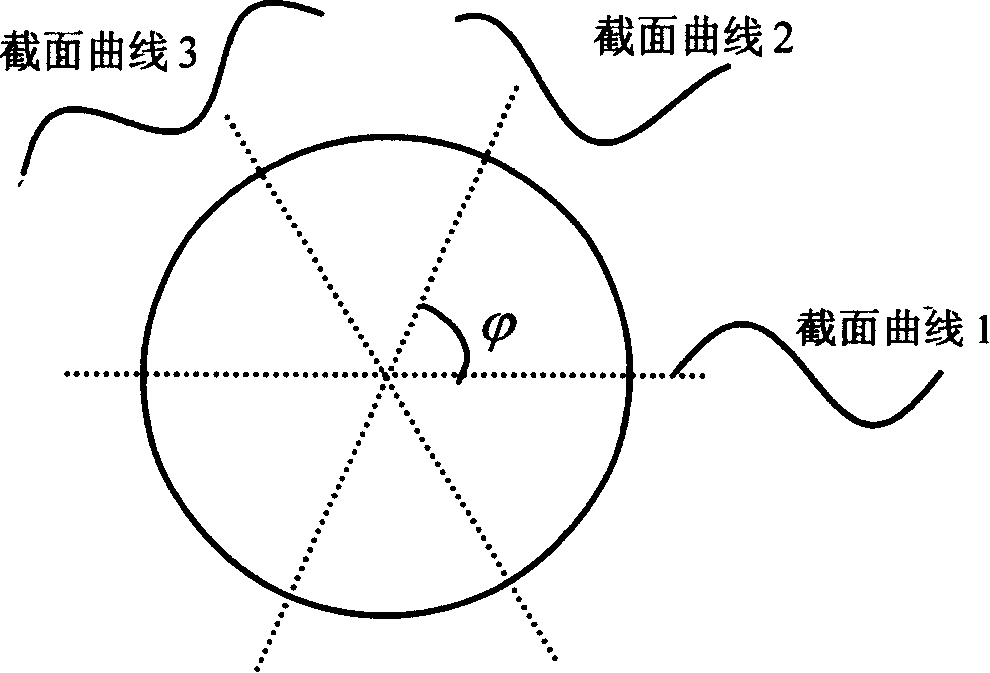

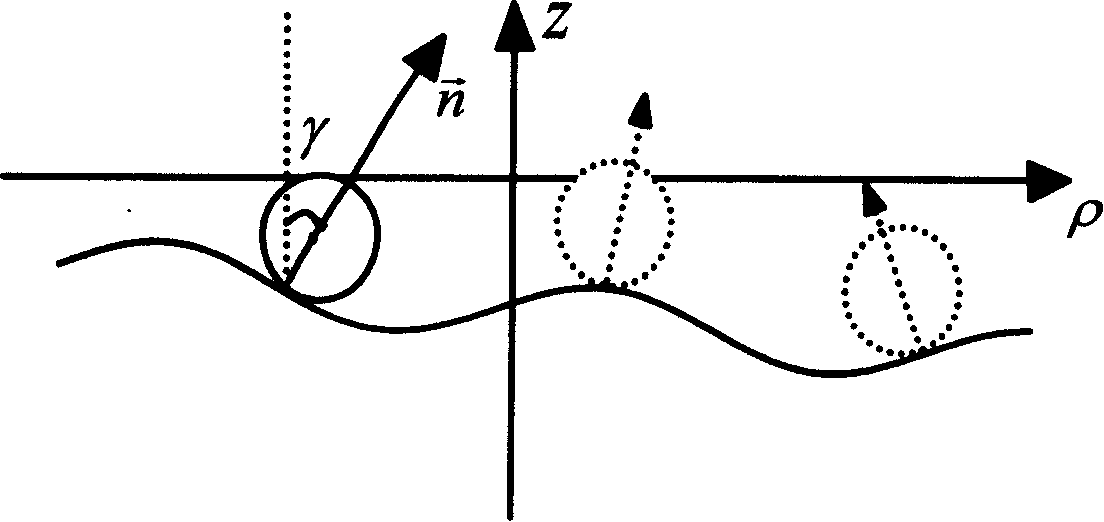

[0029] For the processing model of any free-form surface z=f(x, y), it is very difficult to directly find the curvature of the surface and the characteristics of the concave region in three-dimensional space. Here, it is proposed to use the rotating section analysis method for the processing model to carry out the above two Quantita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com