Fluid drop ejection

A fluid injection and fluid technology, applied in the direction of injection devices, printing, single handheld devices, etc., can solve the problems of limited effectiveness and achieve the effects of increasing system processing capacity, reducing maintenance downtime, and reducing ink waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

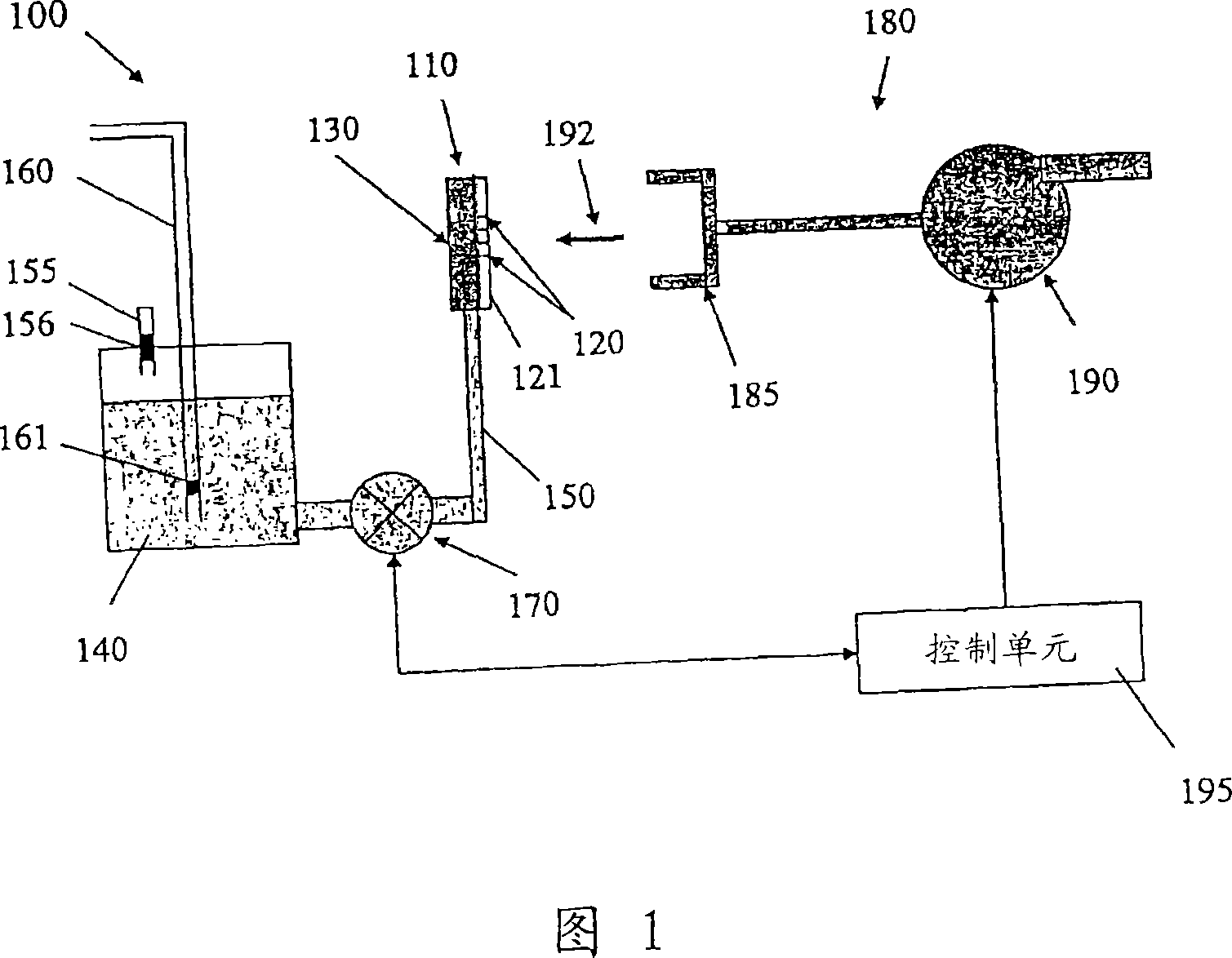

[0020] As shown in FIG. 1 , an inkjet printing system 100 includes an inkjet printhead module 110 having a plurality of ink nozzles 120 arranged generally in an array on a nozzle plate 121, a pumping chamber 130 that supplies ink to the nozzles 120, a reservoir An ink reservoir 140 for ink to be supplied to the pumping chamber 130 and an ink channel 150 for fluid communication between the ink reservoir 140 and the pumping chamber 130 . During printing, ink droplets are ejected from the ink nozzles 120 in response to input image data to form an image ink dot pattern on the ink receiver.

[0021] Inkjet printhead module 110 may be in the form of piezoelectric inkjet, thermal inkjet, MEMS inkjet based printheads, and other types of ink actuation mechanisms. For example, US 5,265,315 to Hoisington et al., the entire content of which is hereby incorporated by reference, describes a printhead having a semiconductor printhead body and piezoelectric actuators. The printhead body is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com