Combined marsh gas fermentation pool

A biogas fermentation and combined technology, which is used in gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problems of difficulty in cleaning slag and increase costs in biogas digesters, and achieve the effect of ensuring medium-temperature operation and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

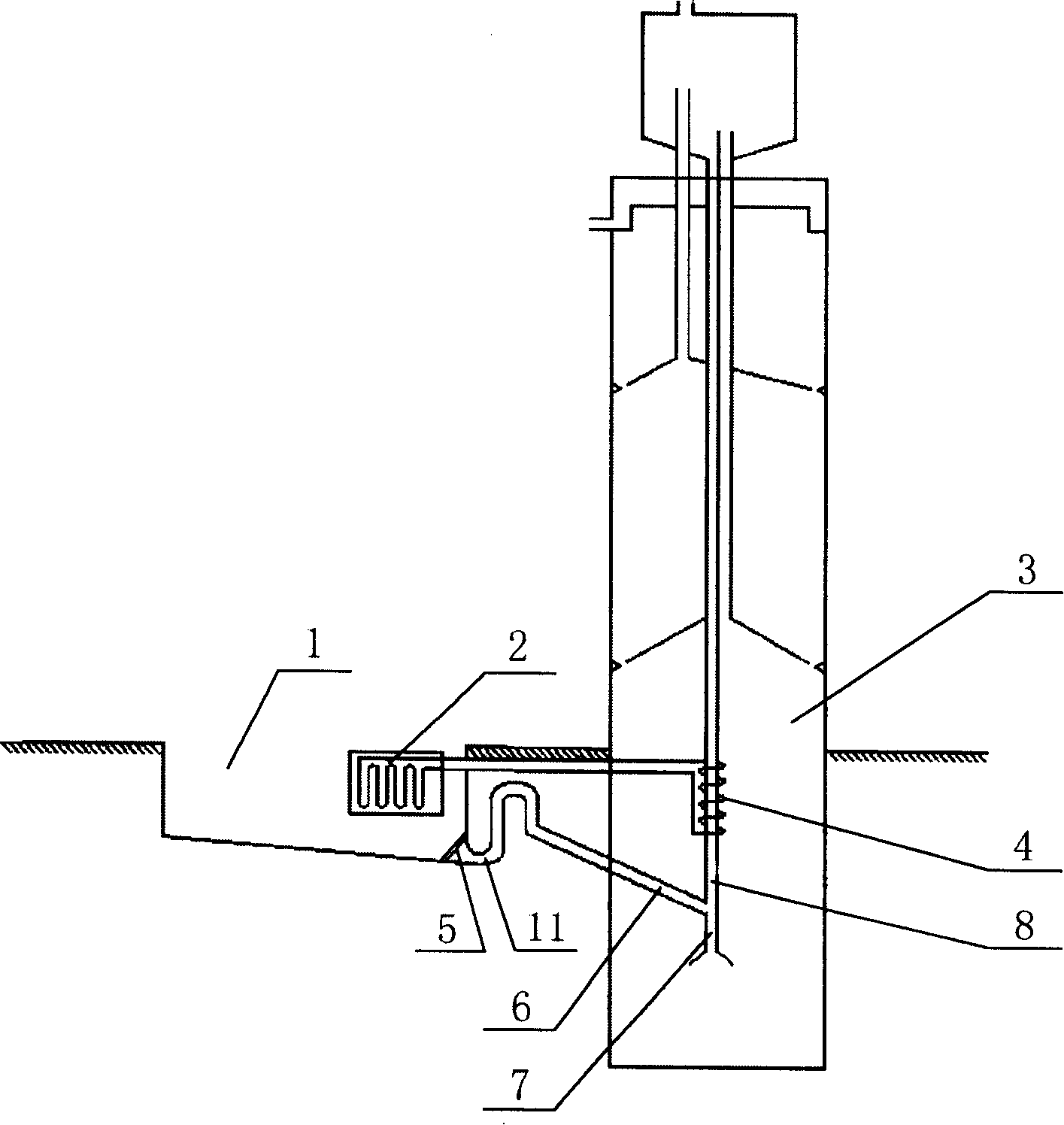

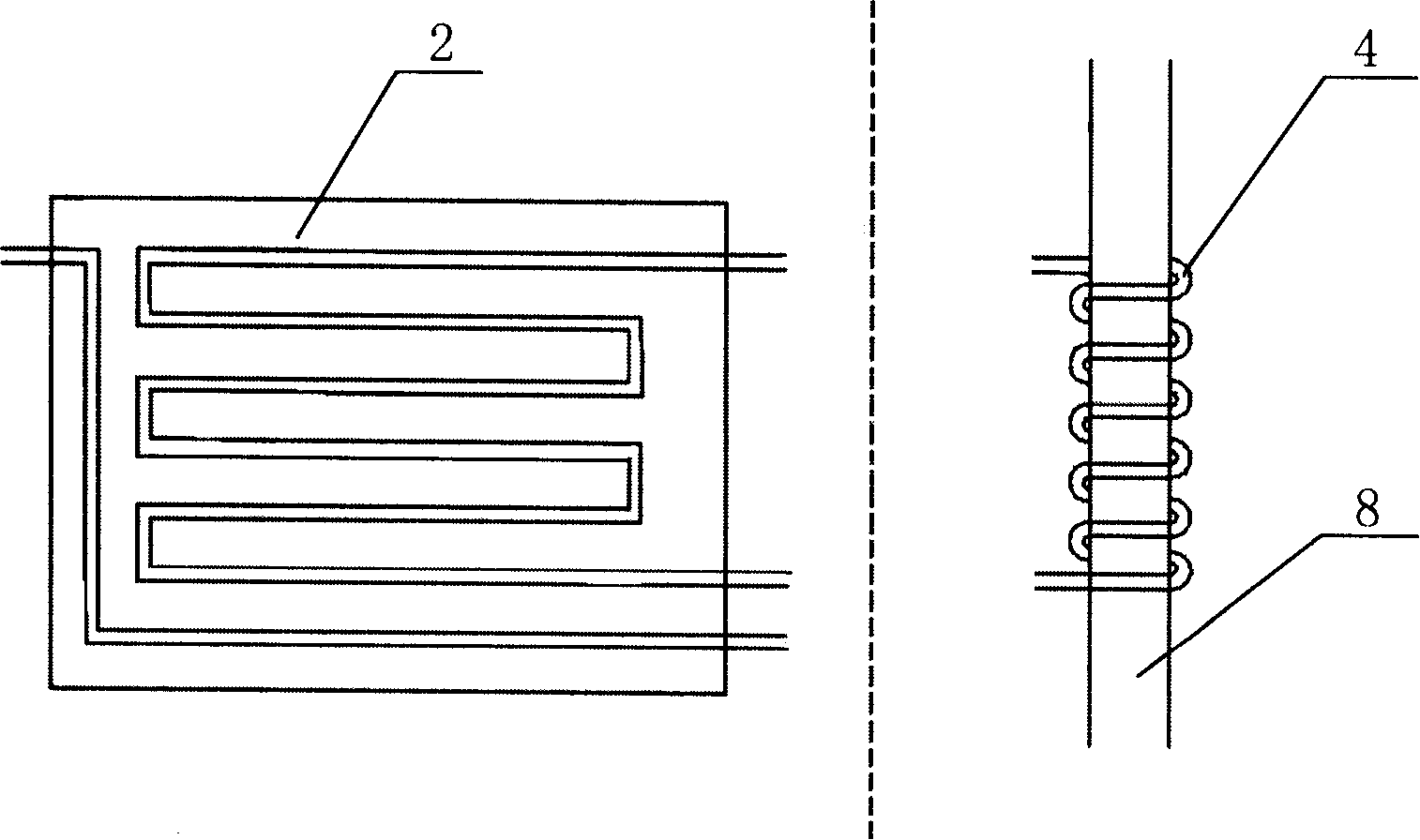

[0022] see figure 1 , figure 1 It is a schematic diagram of the structure of the combined biogas tank of the present invention; the structure of the combined biogas fermentation tank of the present invention is composed of a stack retting tank 1 and an internal circulation (IC) biogas reactor 3 . The retting tank 1 performs pretreatment on the biogas solid raw material while stacking retting, which solves the contradiction between the feeding and slag discharge of the solid raw material. These crops or agricultural product processing discards are subjected to aerobic fermentation in the retting tank, and the fermented acid solution is used as a biogas raw material and then enters the biogas reactor to produce gas, realizing the solid-liquid separation and pretreatment of solid raw materials; at the same time, the biogas reaction The biogas slurry discharged from the device flows to the retting tank to supplement the water and provide microorganisms for the solid raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com