Supply pump

A technology for supplying pumps and plungers, used in fuel injection pumps, engine components, machines/engines, etc., to solve problems such as burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] [Structure of the embodiment]

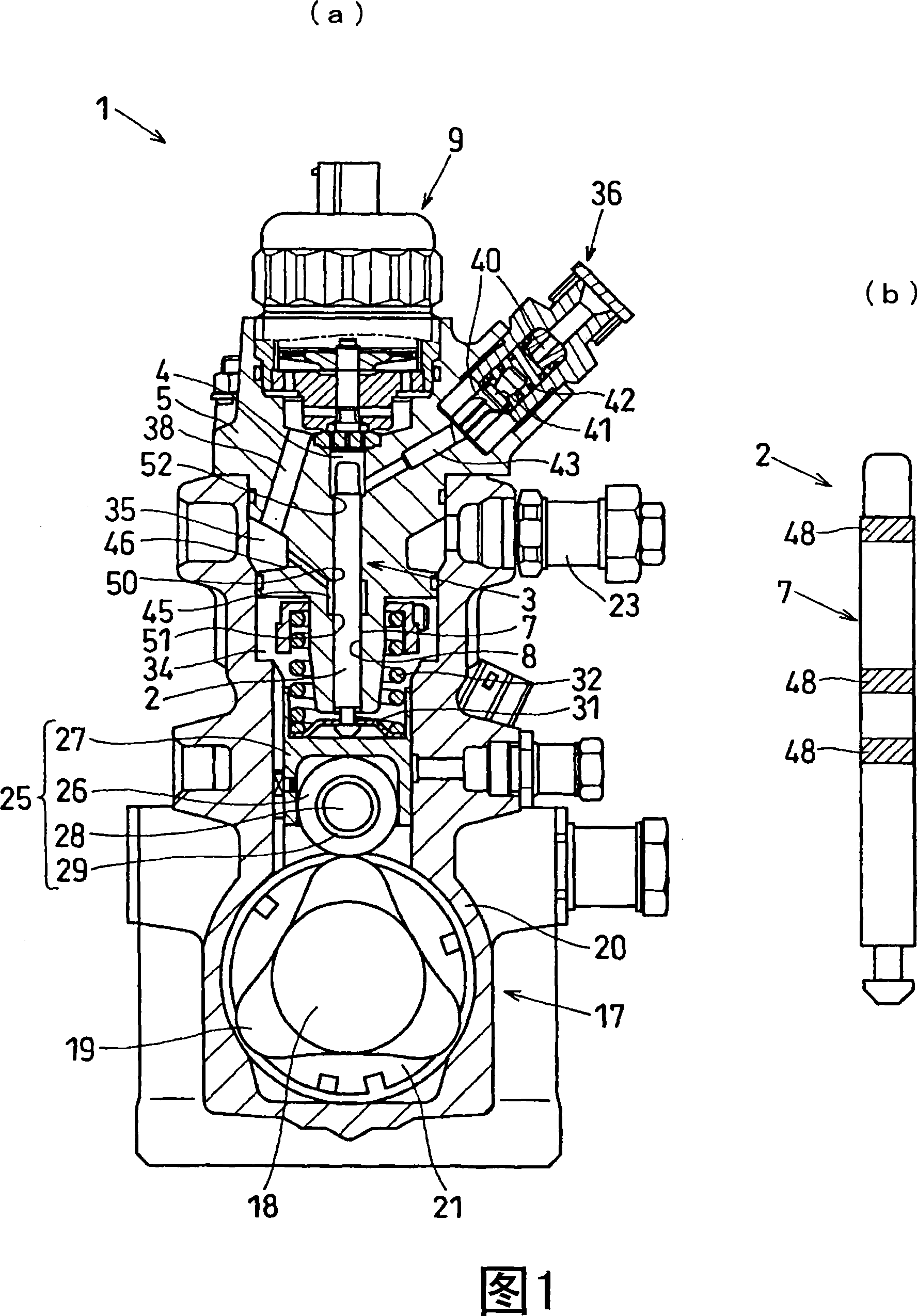

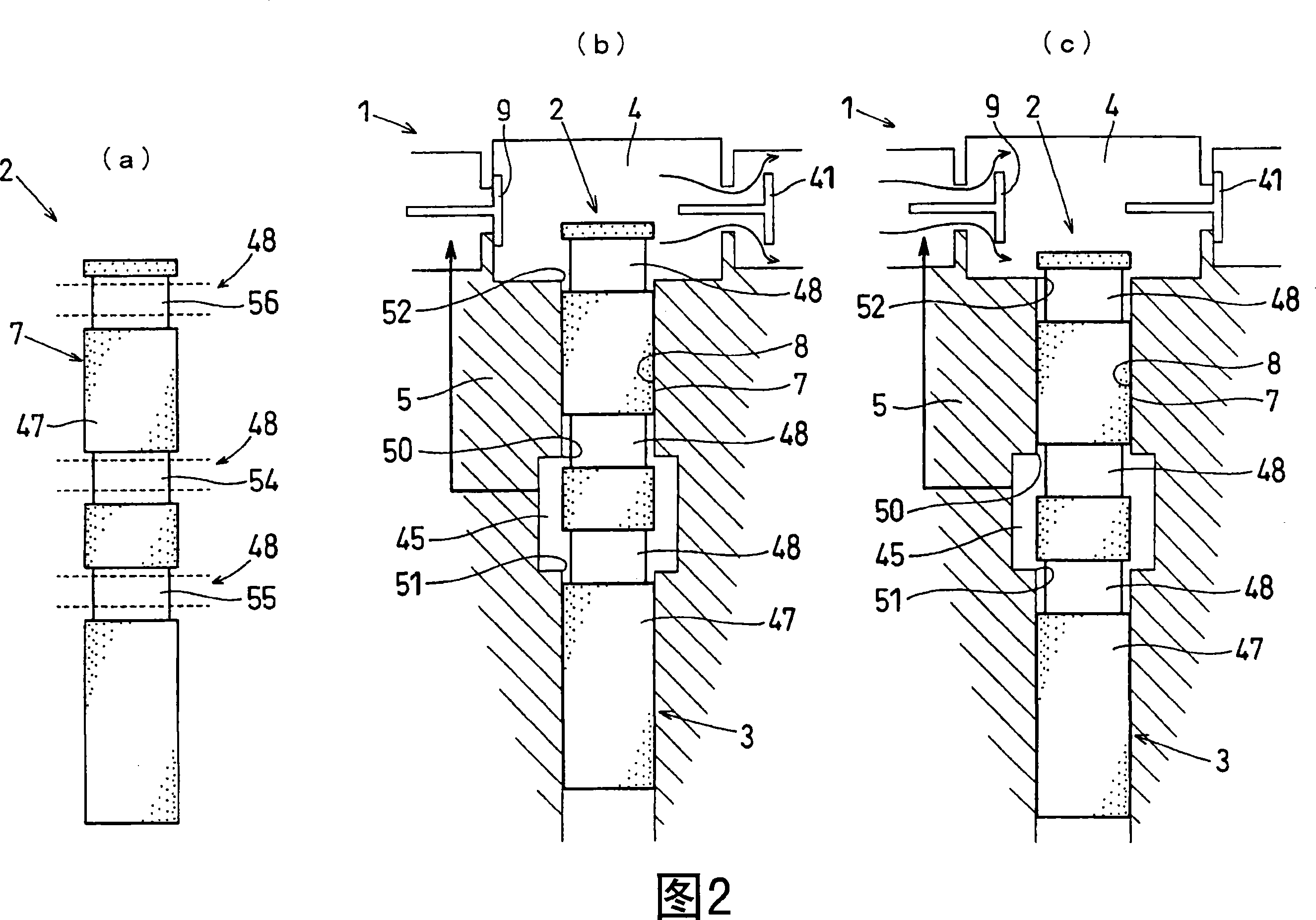

[0022] The structure of the supply pump 1 of an embodiment is demonstrated using FIG.1 and FIG.2.

[0023] The supply pump 1 is provided with a plunger 2 that is moved up and down in the axial direction by applying a driving force from a predetermined drive source, and a cylinder 3 that accommodates the plunger 2 in an axially slidable manner, and uses the upper part of the cylinder 3 as a pressurized pump for fuel. The cylinder 5 of the chamber 4 sucks fuel into the pressurized chamber 4 in response to the vertical movement of the plunger 2 and discharges the fuel in the pressurized chamber 4 under pressure.

[0024] In addition, the discharged fuel is supplied to, for example, a common rail (not shown) to accumulate pressure in a high-pressure state, and is supplied from the common rail to an injector (not shown) to be injected into a cylinder of an engine (not shown). Inside. In addition, drive control of the supply pump 1, injectors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com