Mask plate, mask plate layout design method and defect repairing method

A mask and defect detection technology, applied in the field of masks, can solve problems such as inability to repair and inability to locate, so as to reduce the risk of scrapping and ensure the quality of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] The processing method of the present invention can be widely applied in many applications, and can utilize many suitable materials to make, and below is to illustrate by preferred embodiment, certainly the present invention is not limited to this specific embodiment, this field Common replacements known to those skilled in the art undoubtedly fall within the protection scope of the present invention.

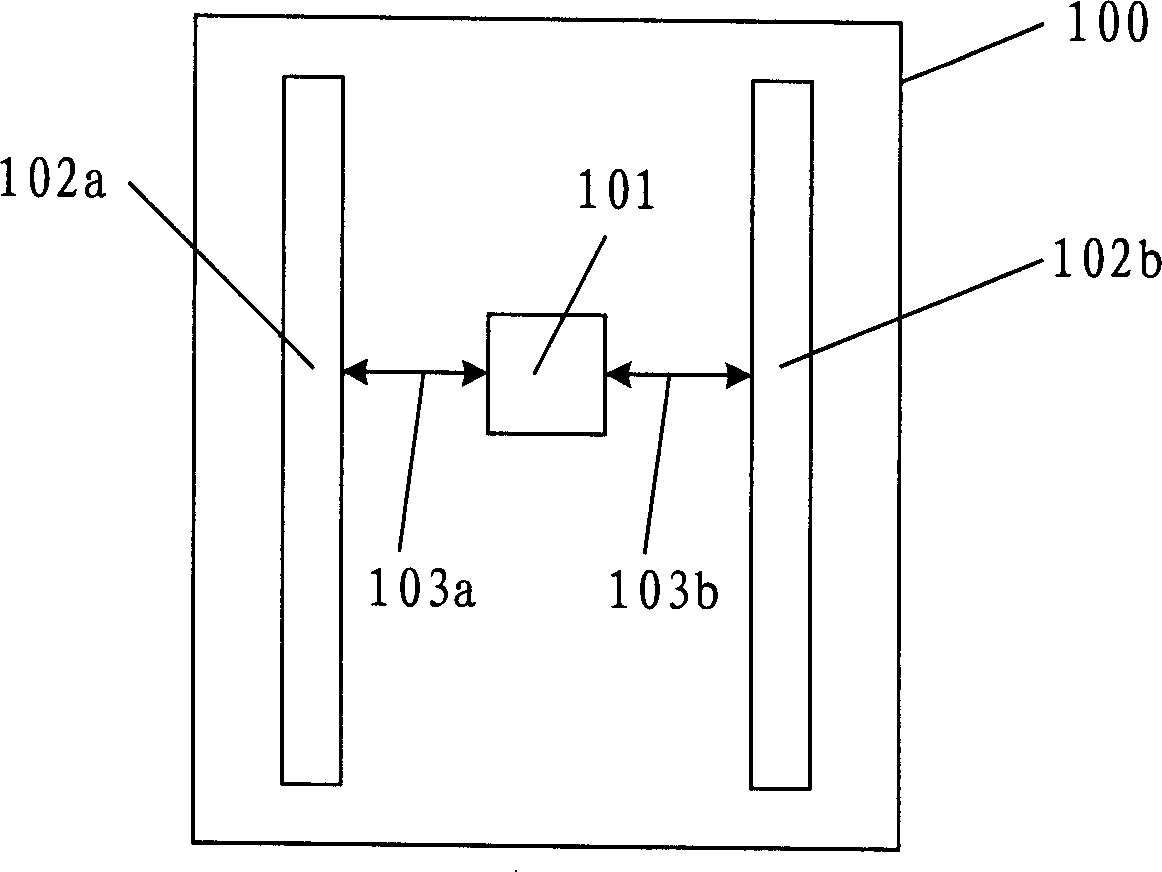

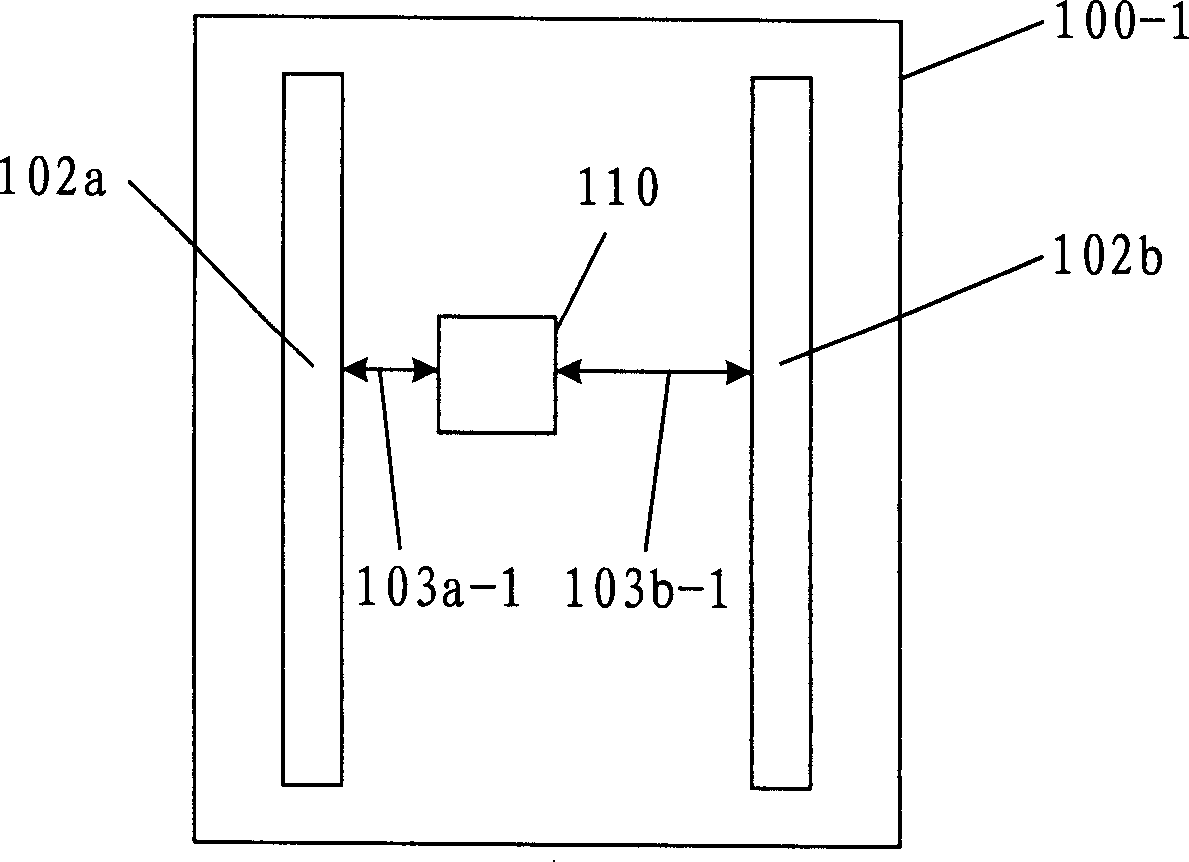

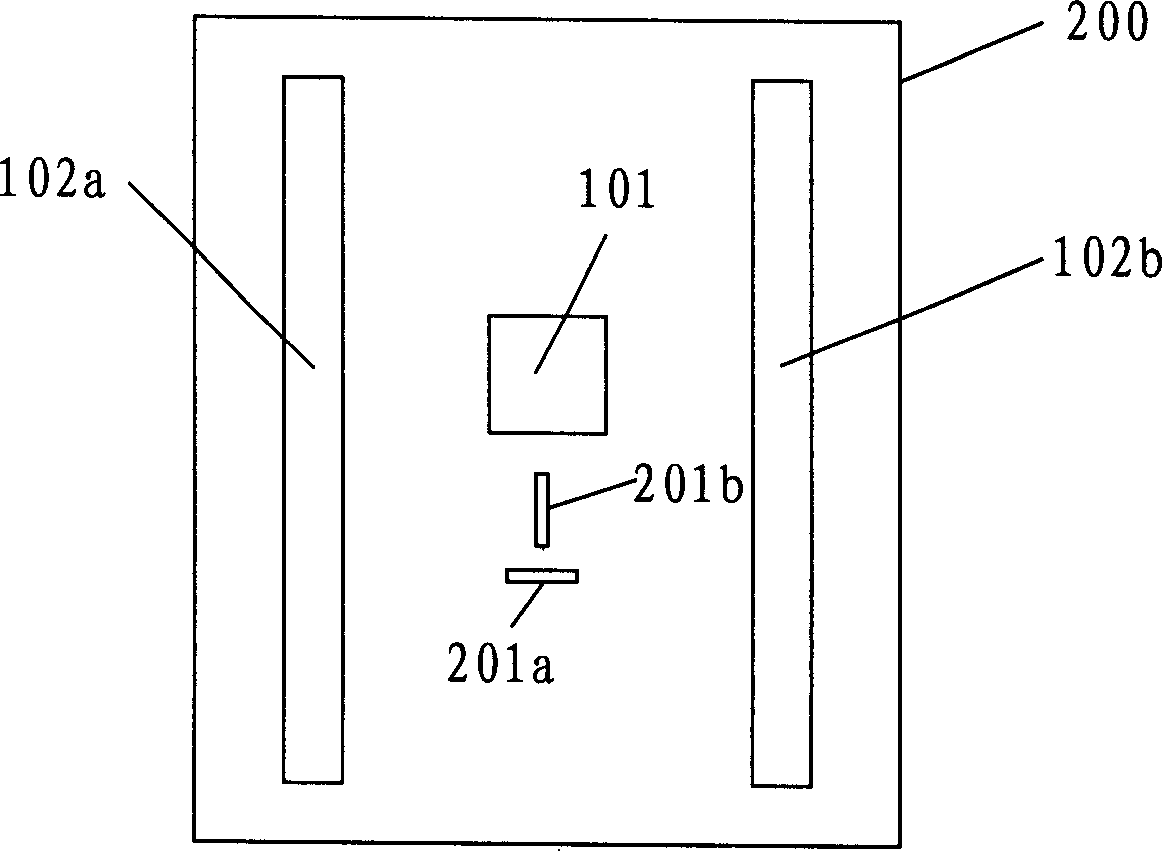

[0038] In order to repair every defect on the mask, it is necessary to realize that the defects appearing at any position on the mask can be accurately located. Existing reticles have geometry that needs to be transferred to the wafer surface during semiconductor fabrication. The geometry is determined by the layout of devices, me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com