Shallow ditch groove separation process monitoring domain and monitoring method

A shallow trench, layout technology, used in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., to achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

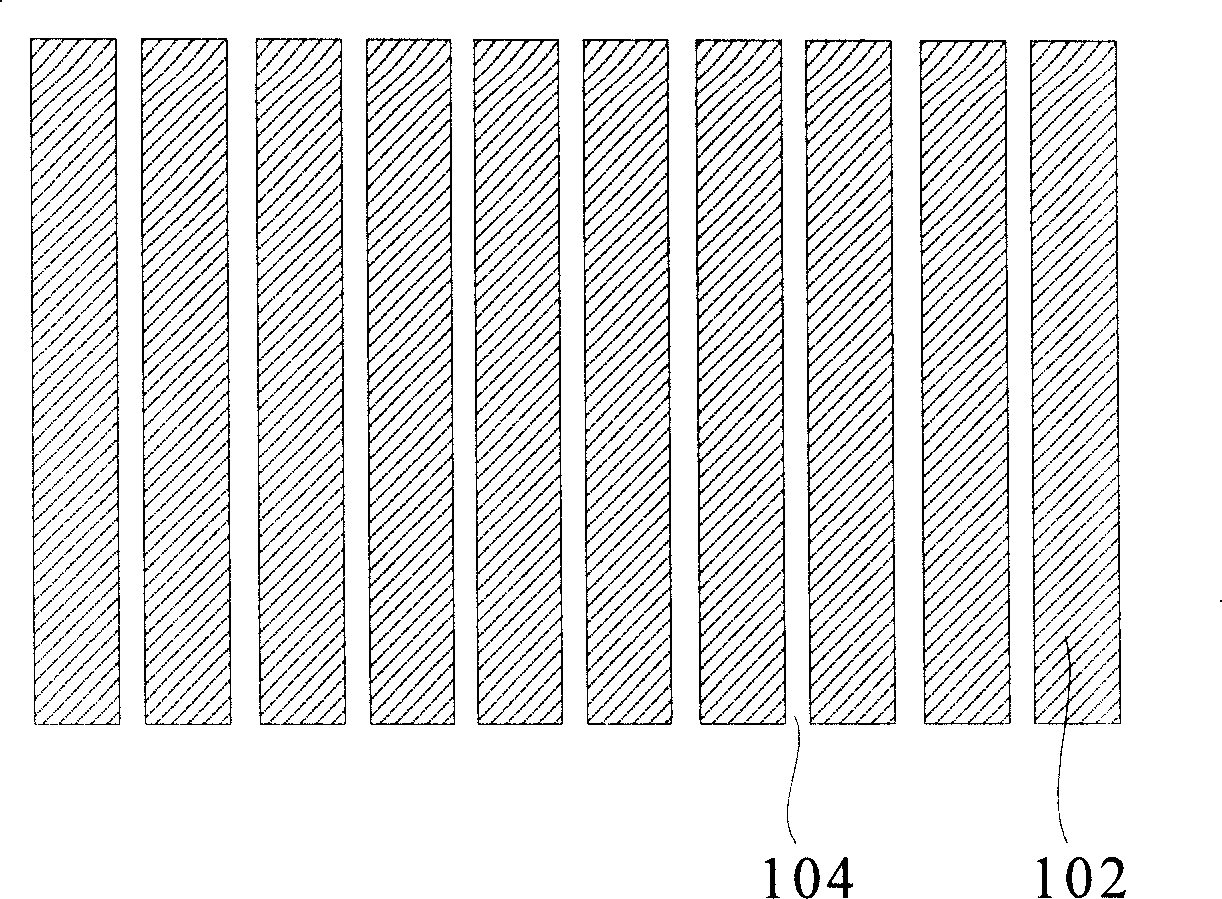

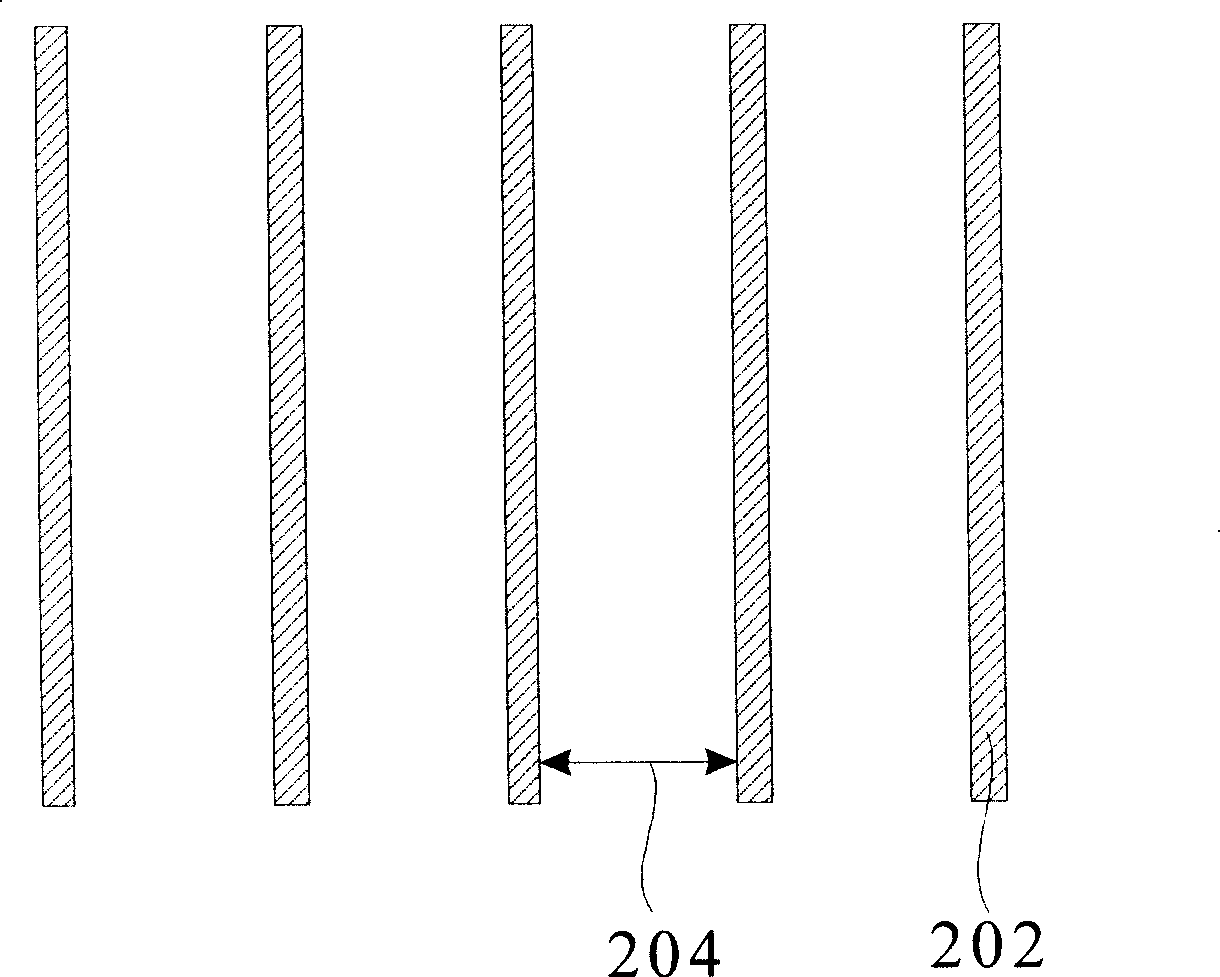

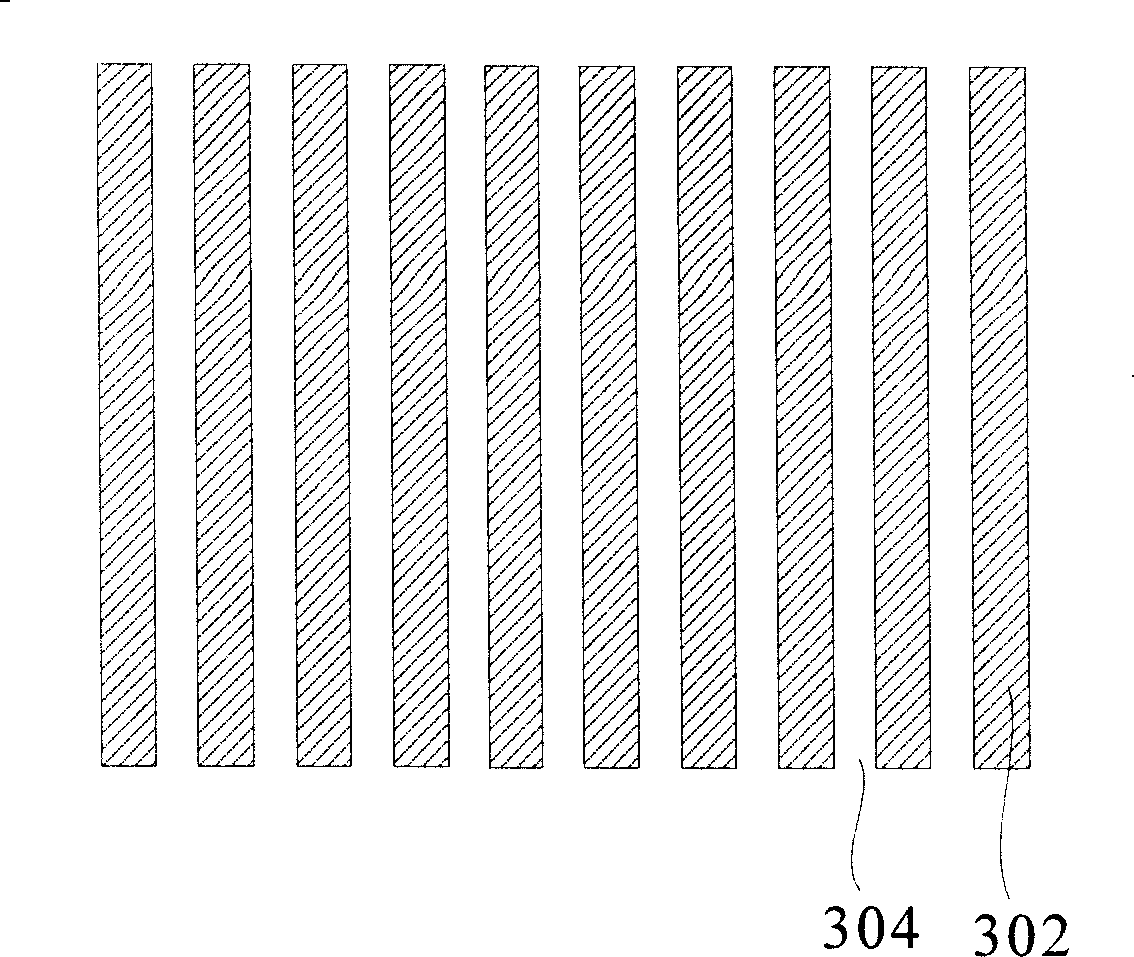

[0040] When the process size shrinks from 90nm technology node to 65nm technology node, according to the design rule (design rule), the aspect ratio of shallow trench isolation (STI) increases from 3.5 at 90nm to 5 at 65nm. , and the design of the shallow trench isolation density is different for different products, which brings great difficulties to the etching process of the trench and the subsequent deposition and planarization process. How to monitor the process window and process stability of the shallow trench process will also become very important.

[0041] The invention provides a monitoring layout of shallow trench isolation process, which is used to monitor the process window of shallow trench isolation, including: complex g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com