Non-needle positive pressure enclosed transfusion joint valve

A joint valve, liquid technology, applied in the directions of valves, hypodermic injection devices, and devices introduced into the body, etc., can solve the problems of cumbersome operation, troublesome operation, and needle stick injuries for medical staff, so as to facilitate clinical fixation and portability, and save materials. The effect of small cost and external size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

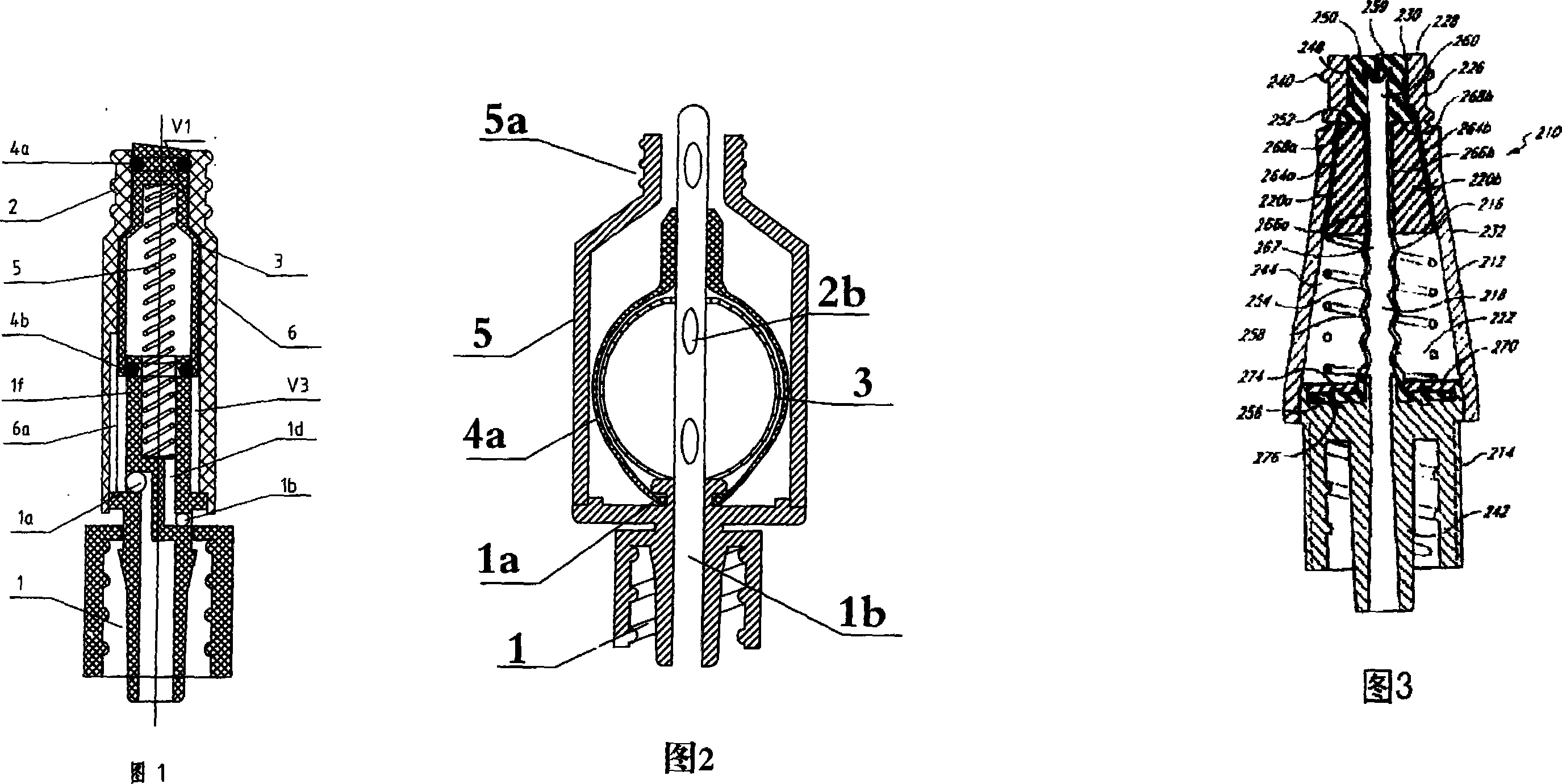

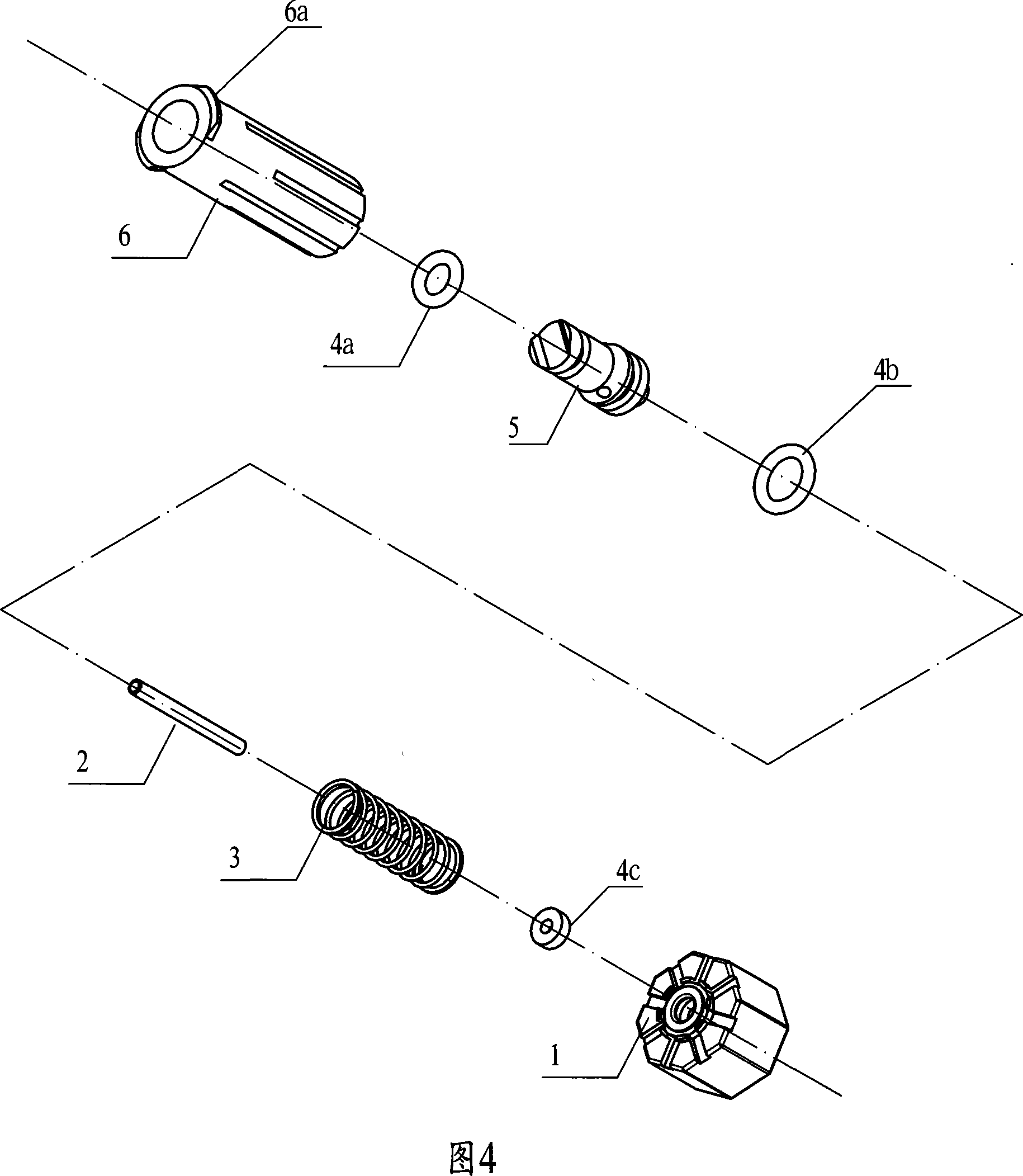

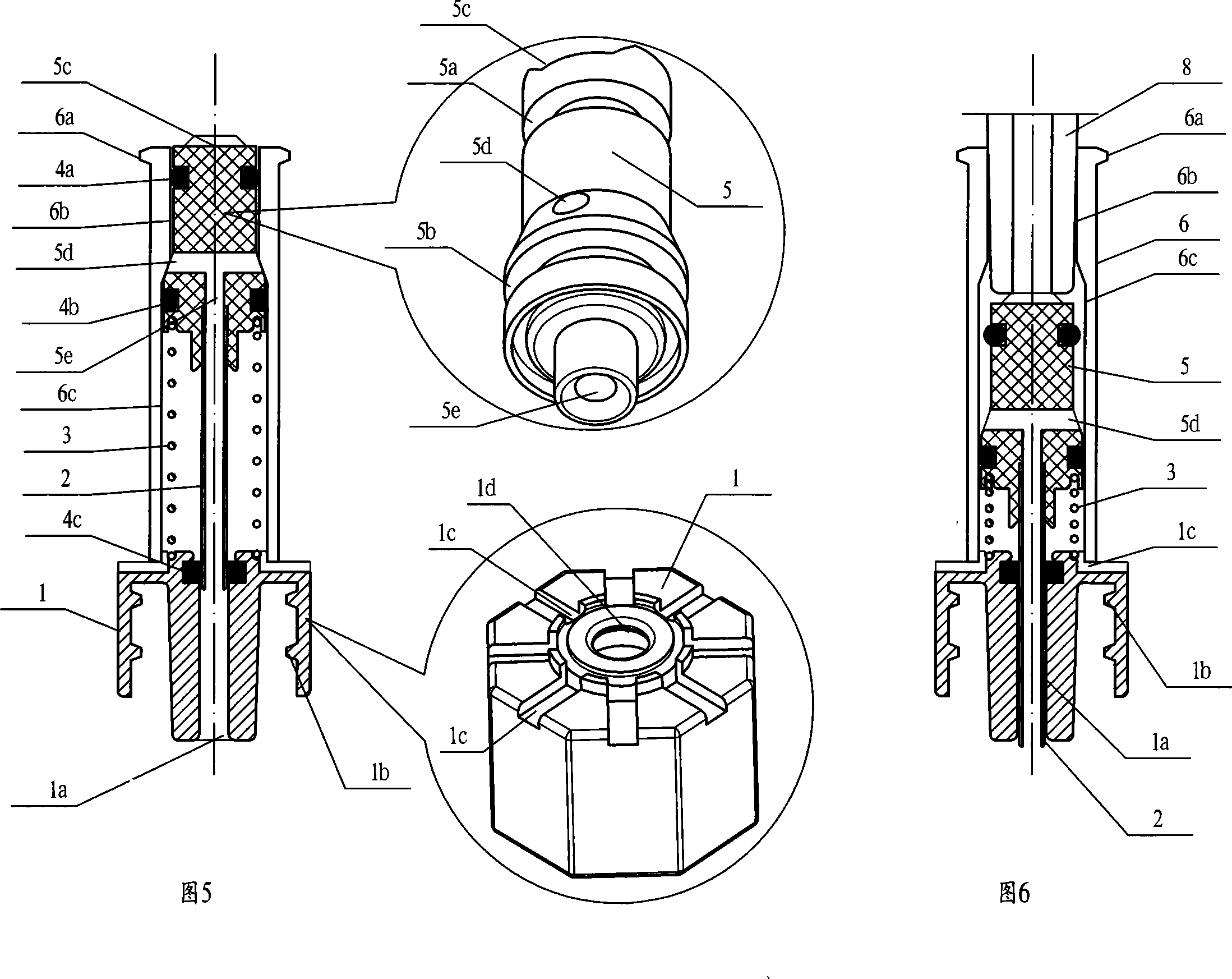

[0031] It can be seen from FIG. 7 that the needleless positive pressure airtight infusion joint valve of the present invention is mainly composed of a housing 6, a piston 5, sealing rings 4a, 4b, 4c, a spring 3, a liquid connecting pipe 2, and a base 1.

[0032] It can be seen from Fig. 8 that the base 1 and the housing 6 constitute the shell of the needle-free airtight infusion joint valve of the present invention, the outer side of the upper end of the housing 6 is threaded to form a screw socket 6a of the Luer structure, and the inner diameter 6c of the lower section of the housing 6 is the inner diameter of the upper section 1.1 times more than 6b, there is a piston 5 in the housing 6 whose outer diameter is compatible with the inner diameter of the housing 6 but can slide up and down. There is a sealing ring 4a, the diameter of the lower section of the piston 5 is more than 1.1 times that of the upper section, the outer edge of the lower end of the piston 5 has an annular ...

specific Embodiment 3

[0034] It can be seen from Fig. 10 that the needleless positive pressure airtight infusion joint valve of the present invention is mainly composed of a housing 6, a piston 5, sealing rings 4a, 4b, a spring 3, a liquid connecting pipe 2A, and a base 1.

[0035] It can be seen from Fig. 11 that the base 1 and the housing 6 constitute the shell of the needle-free airtight infusion joint valve of the present invention, the outer side of the upper end of the housing 6 is threaded to form a screw socket 6a of the Luer structure, and the inner diameter 6c of the lower section of the housing 6 is the inner diameter of the upper section 1.1 times more than 6b, there is a piston 5 in the housing 6 whose outer diameter is compatible with the inner diameter of the housing 6 but can slide up and down. There is a sealing ring 4a, the diameter of the lower section of the piston 5 is more than 1.1 times that of the upper section, the outer edge of the lower end of the piston 5 has an annular g...

specific Embodiment 4

[0037]It can be seen from FIG. 13 that the needleless positive pressure airtight infusion joint valve of the present invention is mainly composed of a housing 6, a piston 5, sealing rings 4a, 4b, a spring 3, a liquid connection hose 2B, and a base 1.

[0038] It can be seen from Fig. 14 that the base 1 and the housing 6 constitute the shell of the needle-free airtight infusion joint valve of the present invention, the upper end of the housing 6 is threaded on the outer side to form the screw socket 6a of the Luer structure, and the inner diameter 6c of the lower section of the housing 6 is the inner diameter of the upper section 1.1 times more than 6b, there is a piston 5 in the housing 6 whose outer diameter is compatible with the inner diameter of the housing 6 but can slide up and down. There is a sealing ring 4a, the diameter of the lower section of the piston 5 is more than 1.1 times that of the upper section, the outer edge of the lower end of the piston 5 has an annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com