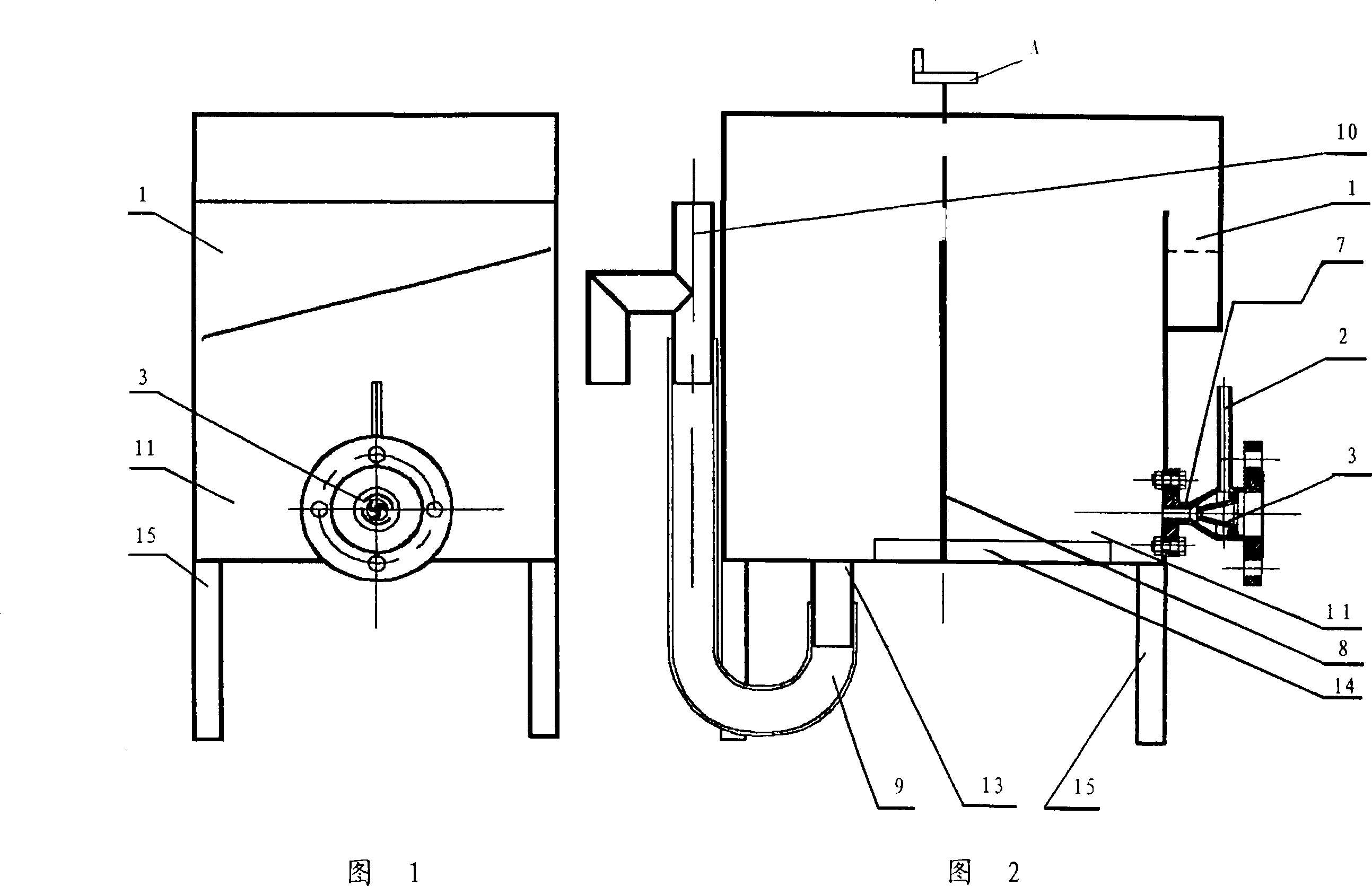

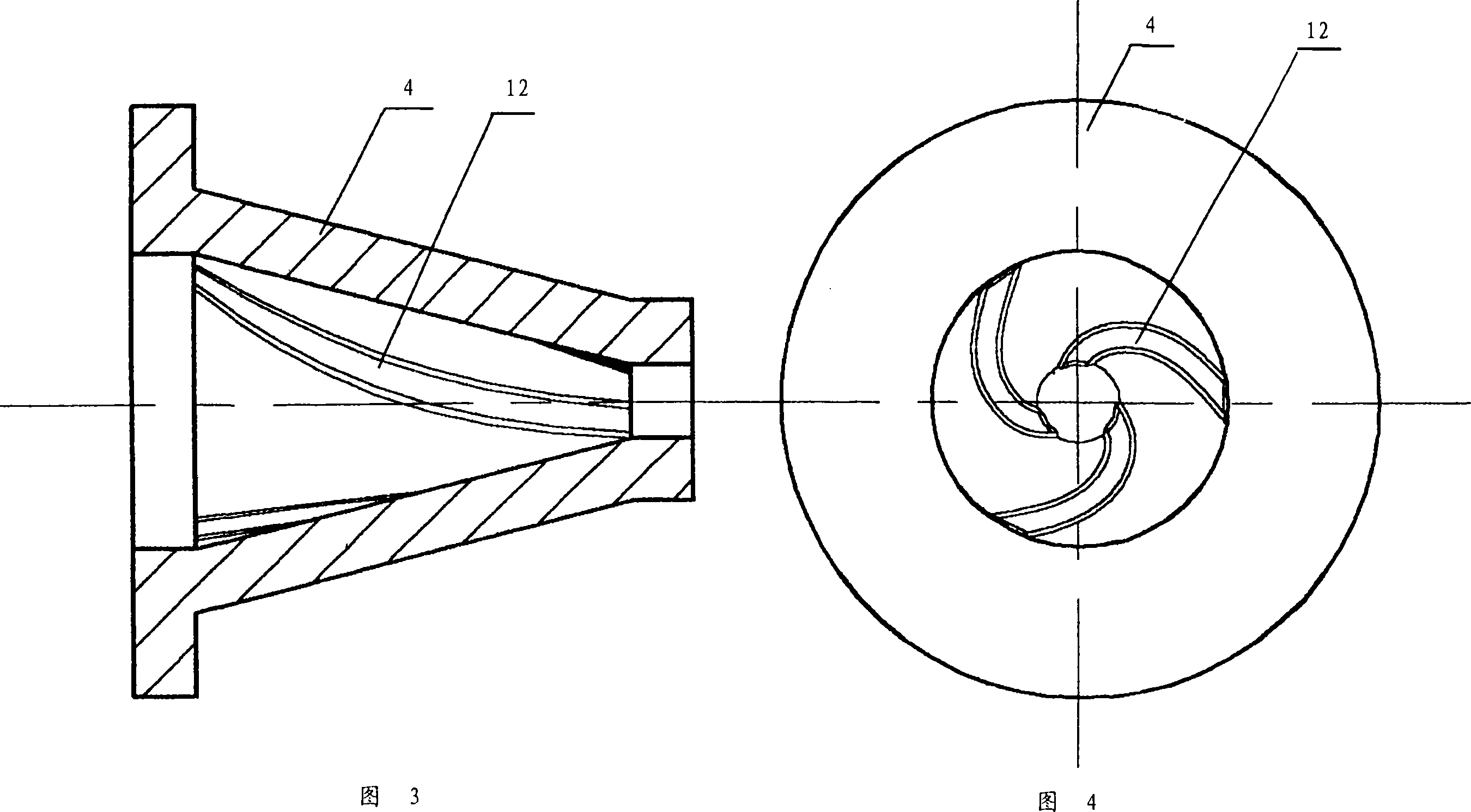

Ore slurry rotational flow floatation method rotational flow flotation column and flotation unit used thereof

A flotation column and pulp technology, which is applied in the field of swirl flotation column and flotation device, swirl flotation, and mineral flotation, can solve the problem of unacceptable mineral processing manufacturers, small investment, difficulty in finding reasons, and accountability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

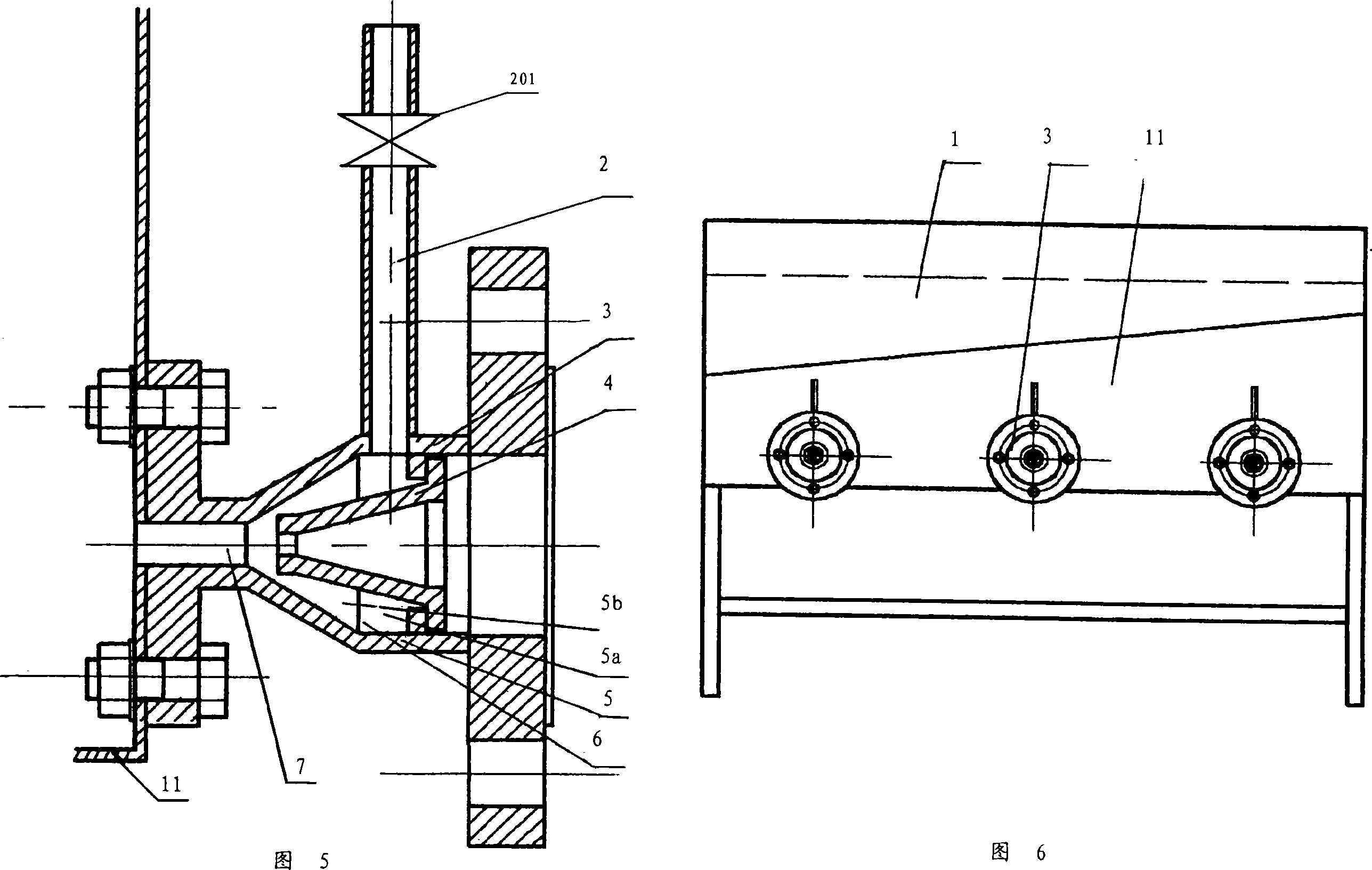

[0150] Through the industrial test of lead-zinc ore lead / zinc-sulfur, lead is extracted from the pulp by cyclone flotation. Through the test, it is found that the best condition of regulating potential flotation separation and regulating frequency conversion feeding pressure is: the pressure of feeding pulp is: 3.00 kg / cm 2 ; The volume of air inhaled by the swirl jet suction foamer (negative pressure) is 0.35 meters 3 / min; the baffle plate of the flotation tank (directly opposite to the ore nozzle) is adjusted to 60% of the front and rear distance to control the micro-bubble effect of the pulp; the average diameter of the pulp foam is 0.60 cm; the pulp foam layer is 30 cm; the pH of the pulp is 12.45, The pulp potential is 170mV, diethylsulfide nitrogen (DDTC) is used as the main collector for lead selection, lime is used as the adjustment and stabilizer of pH and pulp potential, the concentration, flow and grade of the pulp are monitored, and the concentration and flow of ...

Embodiment 2

[0152] Adjust the valve to control the amount of air inhaled by the swirl injector (negative pressure) and the baffle of the flotation tank (directly opposite to the ore feeding nozzle) to adjust the front and rear distances, and adjust the slurry potential and pH value. With the increase of lime consumption, the pH of the slurry increases , the slurry potential decreases, and at the same time the ore grade and lead recovery rate of the lead coarse concentrate gradually increase, when the pressure of the ore slurry is: 3.50 kg / cm 2 ;Valve control swirl injector (negative pressure) suction air volume is 0.40 meters 3 / min; the baffle plate of the flotation tank (directly opposite to the ore nozzle) is adjusted to 50% of the front and rear distance to control the microbubble of the pulp; the average diameter of the pulp foam is 0.50 cm; when the thickness of the foam layer is greater than 35 cm; the pH of the pulp is 12.3 --12.6 within a narrow range, the slurry potential is al...

Embodiment 3

[0154] Tests have proved that the conditions for the optimum foam average diameter and the thickness of the foam layer in the flotation tank for lead / zinc-sulfur regulation and control of flotation separation are: the average diameter of the pulp foam is 0.30 cm; the thickness of the foam layer is greater than 40 cm; The pressure is: 3.00 kg / cm 2 ;The amount of air inhaled by the swirl jet (negative pressure) is 0.45 meters 3 / min; the baffle plate of the flotation cell (directly opposite to the ore nozzle) is adjusted to 50% of the front and rear distance to control the microbubble of the pulp; the pH of the pulp is 12.4, the potential of the pulp is 165mV, and DDTC is used as the main trap for lead selection Receiver. If other parameters are changed, the size of the foam diameter and the thickness of the foam layer of the flotation cell will change accordingly, which will directly affect the recovery rate of ore dressing. When the pressure of the ore feeding slurry is: 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com