High temperature short time ageing effect technique for beryllium bronze manufactured volute heilical spring

A helical spring and beryllium bronze technology, which is applied in the field of heat treatment aging strengthening technology, can solve problems such as greatly increased friction, spring waste, and spring manufacturing failure, and achieve high aging temperature, short aging time, and small deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

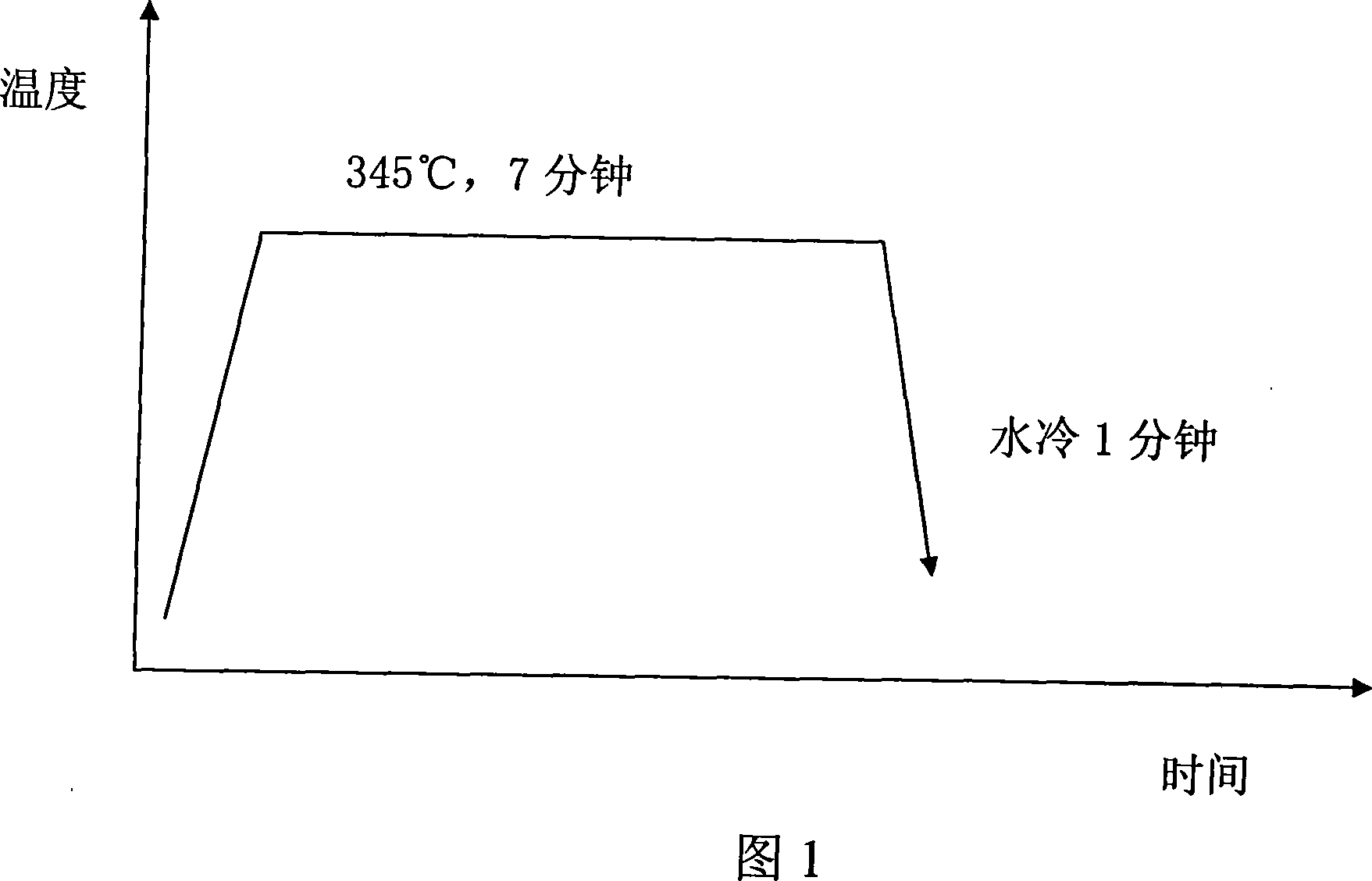

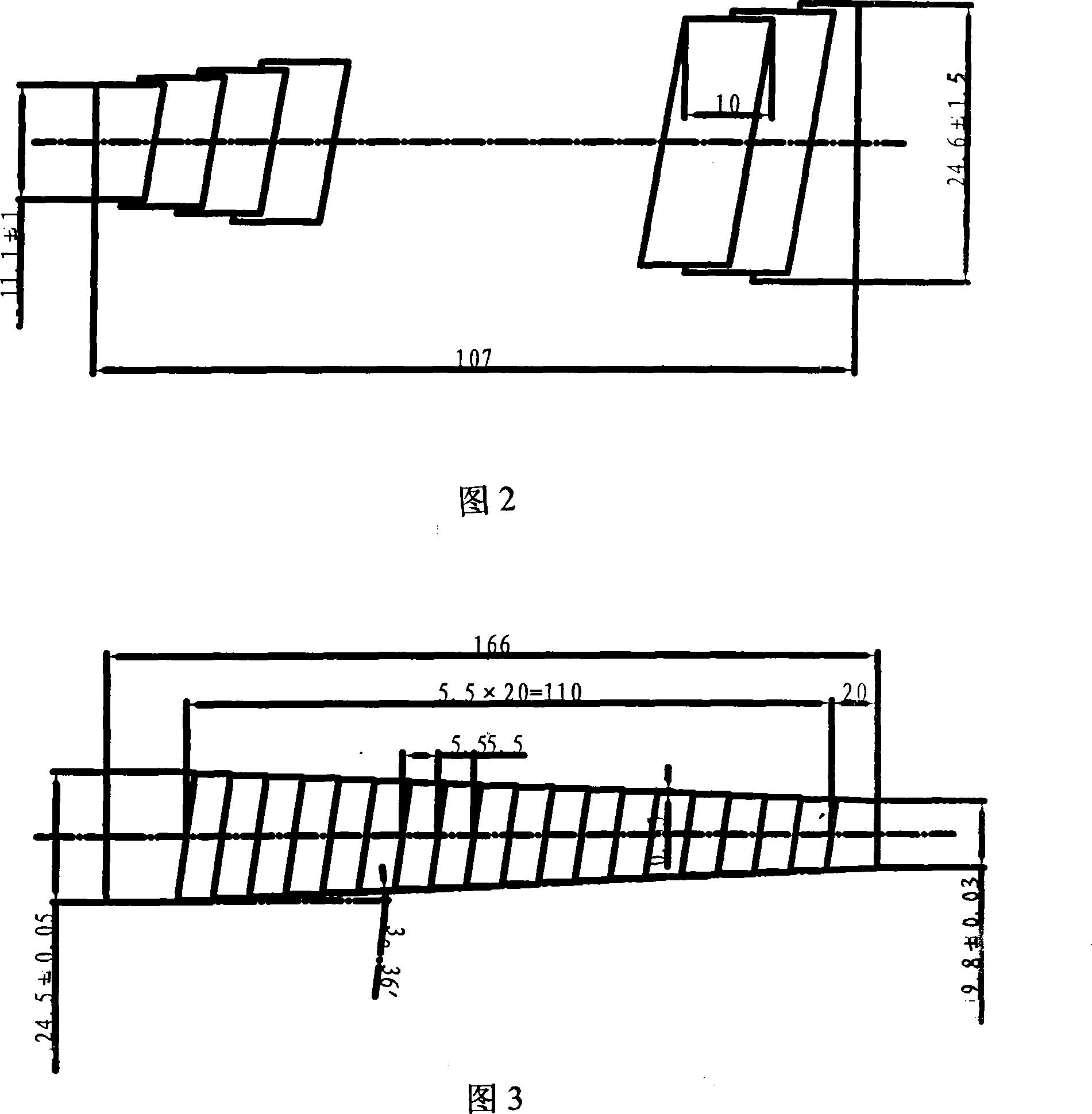

[0012] Example 1: Part name: right sheath spring, material: QBe1.9Cr, raw material state: 780°C, water cooling, supersaturated α solid solution is obtained, and the shape of the part is shown in Figure 2. Technical requirements: ①Rotation: left. ②Total number of turns: 19③Effective number of turns: 17④Tolerance of non-uniformity of lift between turns is 2mm. ⑤The belt thickness is 0.30mm. ⑥Expanded length: 1103 mm. ⑦Heat treatment: aging. ⑧ Acceptance technical conditions shall be implemented according to WJ532-93.

[0013] First use the special spring mandrel shown in Figure 3 (technical requirements: ①The processing surface F is in a spiral shape. ②Direction: left-handed. ③Intercept: 5.5④Left angle: 0345⑤Total number of turns: 20⑥Axis line displacement: 7.25⑦ Material: 35⑧Heat treatment: HRC28-36) The non-ferrous metal material QBe1.9Cr with a width of 10 mm, a length of 1200 mm and a thickness of 0.30 mm is wound into shape, and the beryllium copper sheet at the big end...

example 2

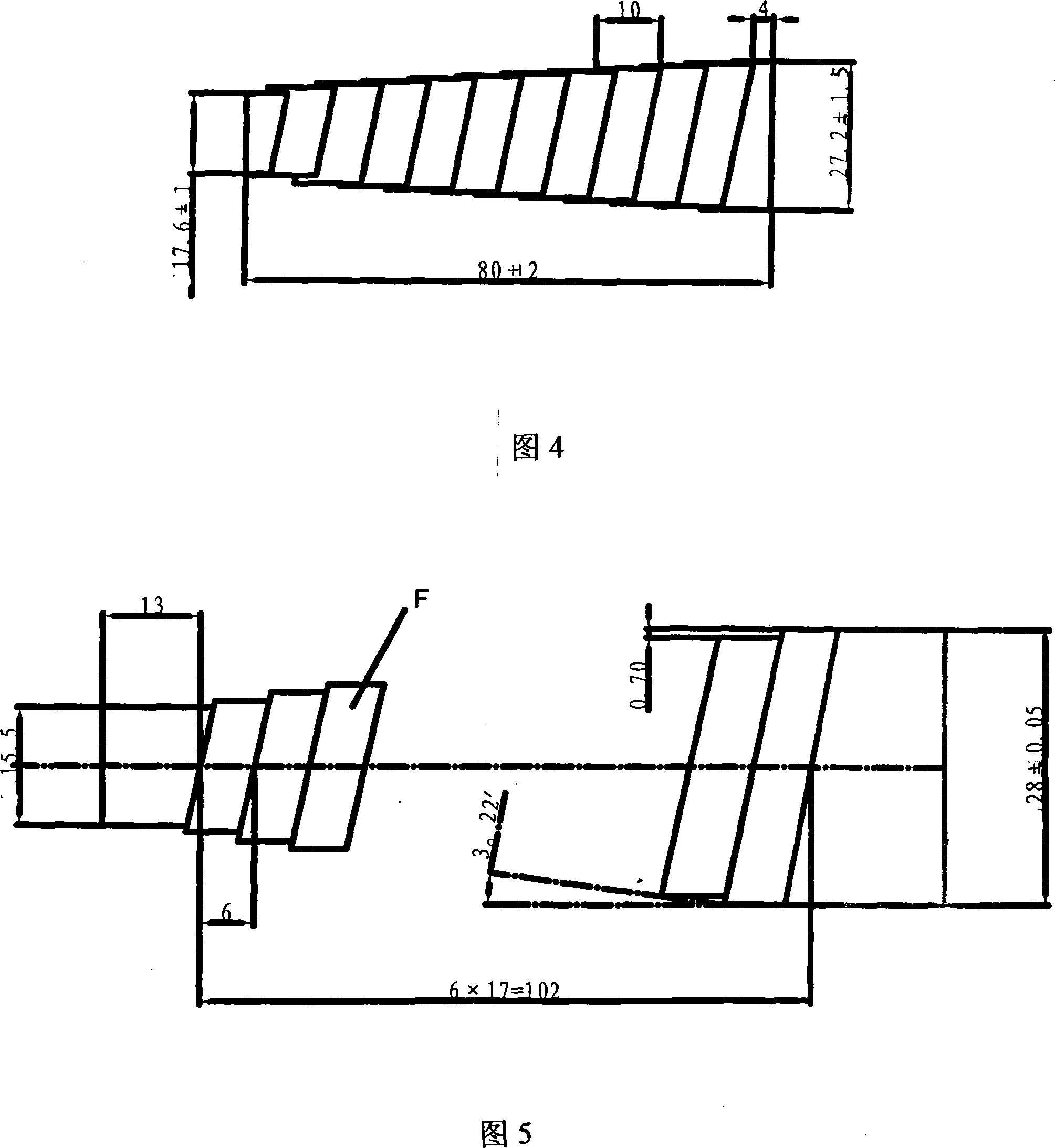

[0014] Example 2: Part name: left sheath spring, material: QBe1.9Cr, raw material state: 780°C, water cooling, to obtain a supersaturated α solid solution state, the shape of the part is shown in Figure 4. (Technical requirements: ① Rotation: left. ② Total number of turns: 12. ③ Effective number of turns: 10. ④ Tolerance of non-uniformity of lift between turns: 2 mm. ⑤ Strip thickness: 0.30 mm. ⑥ Expanded length: 920 mm. ⑦ Heat treatment: Aging. ⑧ Acceptance technical conditions shall be implemented according to WJ532-93.)

[0015] First use the special spring-wound mandrel shown in Figure 5 (technical requirements: ① processing surface F is spiral. ② direction: left-handed. ③ intercept: 6 ④ lift angle: 0352 ⑤ total number of turns: 17 ⑥ axis line displacement: 6 ⑦ material: 35⑧Heat treatment: HRC28-36) The non-ferrous metal material QBe1.9Cr with a width of 10 mm, a length of 950 mm, and a thickness of 0.30 mm is made into a mold, and the beryllium bronze sheet at the big end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com