Nano precipitated phase austenite antimicrobial stainless steel

A technology of antibacterial stainless steel and phase austenite, which is applied in the field of nano-precipitated phase austenite antibacterial stainless steel, can solve the problems of antibacterial stainless steel corrosion resistance decline, etc., and achieve excellent mechanical properties, excellent physical and chemical properties, and simple ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

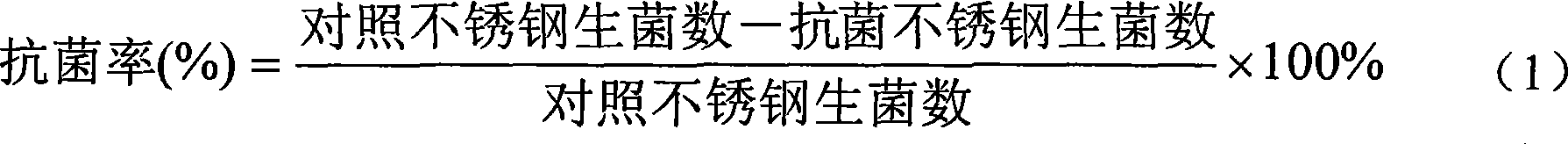

[0011] The preparation of the nano-precipitated phase austenitic antibacterial stainless steel uses austenitic stainless steel as the substrate, adds an appropriate amount of Cu to the substrate, and uses a non-vacuum induction furnace for melting. Before casting, rare earth-magnesium-titanium (RE-Mg- Ti) The composite modifier is broken into small pieces with a particle size of less than 5mm. After drying at a temperature below 240°C, place it at the bottom of the ladle. The amount added is 0.5% to 1.0% of the weight of the molten steel. Composite modification treatment; this is beneficial to degassing and slag removal, purifying molten steel, refining the structure, improving the corrosion resistance and comprehensive mechanical properties of stainless steel. Then antibacterial heat treatment is carried out on the casting. The process is as follows: the first step is to keep the casting at a temperature of 1000°C to 1100°C for 1h to 3h, and air-cool or water-cool to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com