Multifunctional automatization biological sewage treatment composite experimental device

A technology of sewage biological treatment and experimental equipment, which is applied in the field of multifunctional automatic sewage biological treatment combined experimental equipment, can solve the problems of multifunctionality, flexibility of use, reliability of performance, influence of advanced technology, low cost performance, etc. , to achieve the effect of rich content, high cost performance, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The following process is used to treat a certain organic sewage, and the effluent is required to meet the discharge standard.

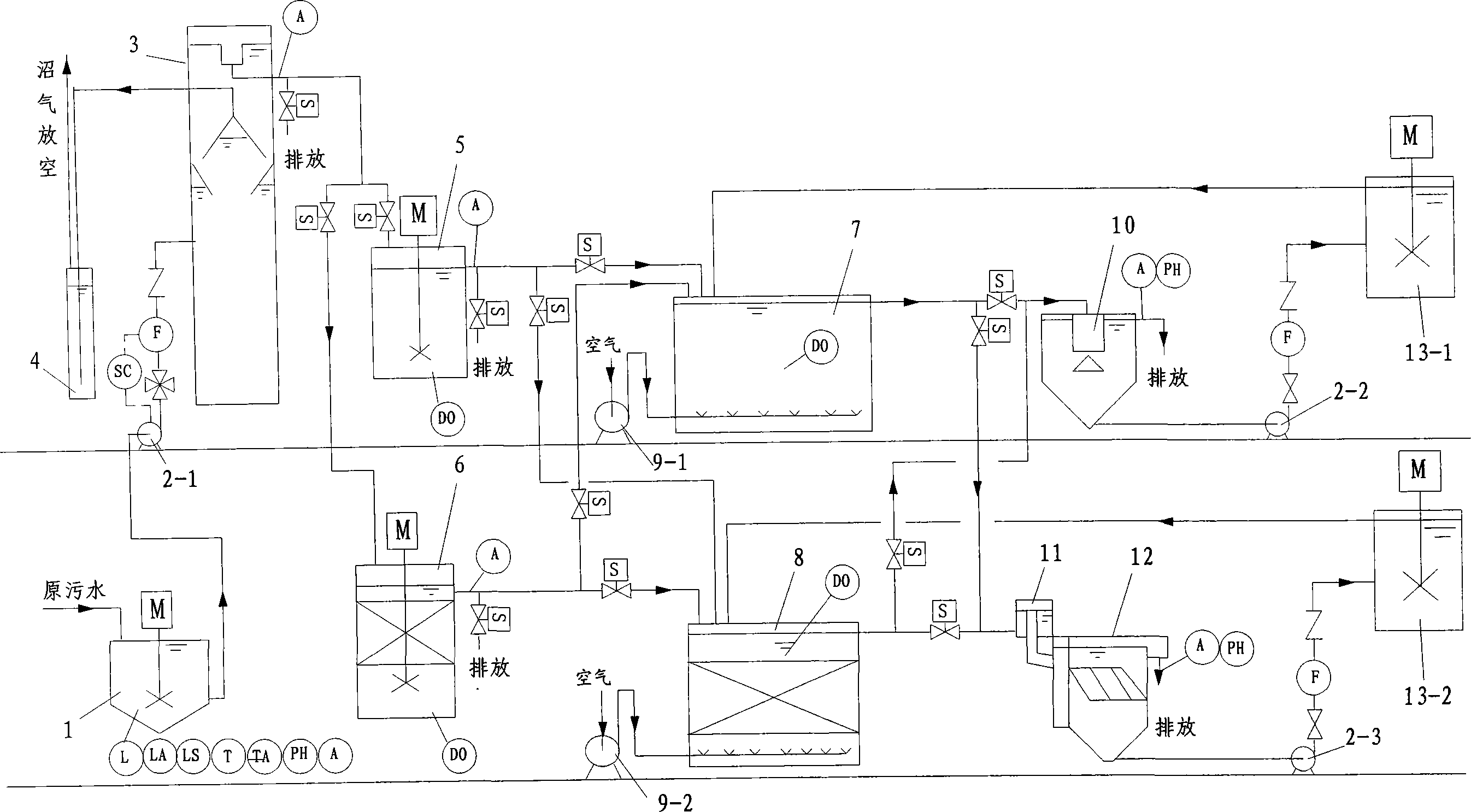

[0045] Raw sewage→regulating tank (A)→pump→UASB→activated sludge anoxic tank→activated sludge aeration tank→vertical sedimentation tank→discharge→biofilm anoxic tank→contact oxidation tank→mixed reaction tank→incline pipe Sedimentation tank → discharge

[0046] (1) Technological process and experimental principle

[0047] The sewage in the regulating tank (A) is pumped into the UASB reactor for anaerobic degradation to remove most of the organic matters. The UASB outlet water flows into the activated sludge anoxic tank and the biofilm anoxic tank respectively, and is mixed with the nitrification liquid returned from the activated sludge aeration tank and the contact oxidation aeration tank respectively to carry out denitrification reaction and remove the sewage nitrogen and some organic matter. The effluent from the activated sludge anoxic t...

Embodiment 2

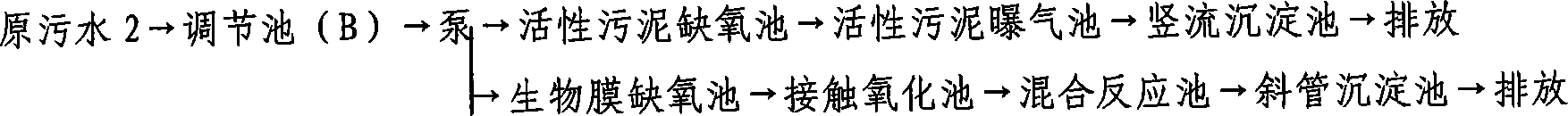

[0066] Use the following operation mode to treat two kinds of organic sewage at the same time, conduct two experiments on the same device at the same time, and require the effluent to meet the discharge standards.

[0067] Raw sewage 1→regulating tank (A)→pump→UASB→discharge

[0068]

[0069] (1) Technological process and experimental principle

[0070] ①Experiment 1

[0071] The raw sewage 1 in the regulating tank (A) is pumped into the UASB reactor for anaerobic degradation, and the organic matter is removed before being discharged.

[0072] ②Experiment 2

[0073] The raw sewage in the regulating tank (B) is pumped into the activated sludge anoxic tank and the biofilm anoxic tank respectively in two ways, and mixed with the nitrification liquid returned from the activated sludge aeration tank and the contact oxidation aeration tank respectively, and then Denitrification reaction to remove nitrogen and some organic matter in sewage. The effluent from the activated slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com