Magnetic storage element and memory

A storage element and storage layer technology, applied in the direction of static memory, digital memory information, electrical components, etc., to achieve the effect of reducing current flow, low power consumption, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

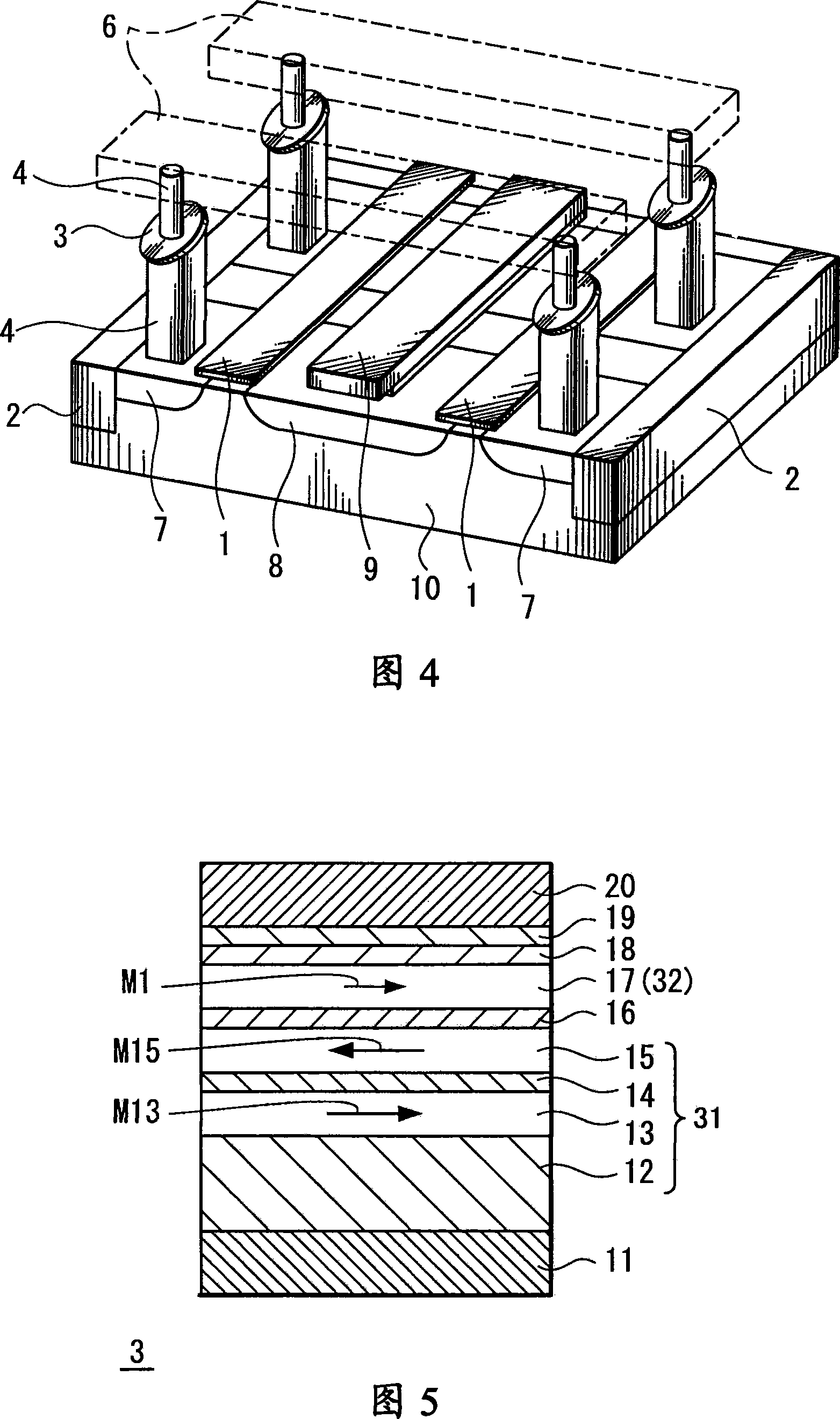

[0198] A thermally oxidized film having a thickness of 2 µm was formed on a silicon substrate having a thickness of 0.575 mm, and the memory element 3 having the configuration shown in FIG. 5 was formed on top of the silicon substrate.

[0199] Specifically, the material and film thickness configured as the memory element 3 shown in FIG. 5 are selected for each layer as follows. A Ta film with a thickness of 3 nm was selected as the bottom layer 11 . PtMn with a thickness of 30 nm is selected as the antiferromagnetic layer 12 . A CoFe film with a thickness of 2.2 nm was selected as the ferromagnetic layer 13 . A CoFeB film having a thickness of 2 nm is selected as the ferromagnetic layer 15 of the magnetization fixed layer 31 . A Ru film having a thickness of 0.8 nm was selected as the nonmagnetic layer 14 of the magnetization fixed layer 31 having a laminated ferromagnetic structure. A MgO film with a thickness of 0.8 nm was selected as the tunnel insulating layer 16 . A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com