Conjunction

A joint and combination technology, applied in the field of joints, achieves the effects of high industrial utilization value, saving manufacturing costs, and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

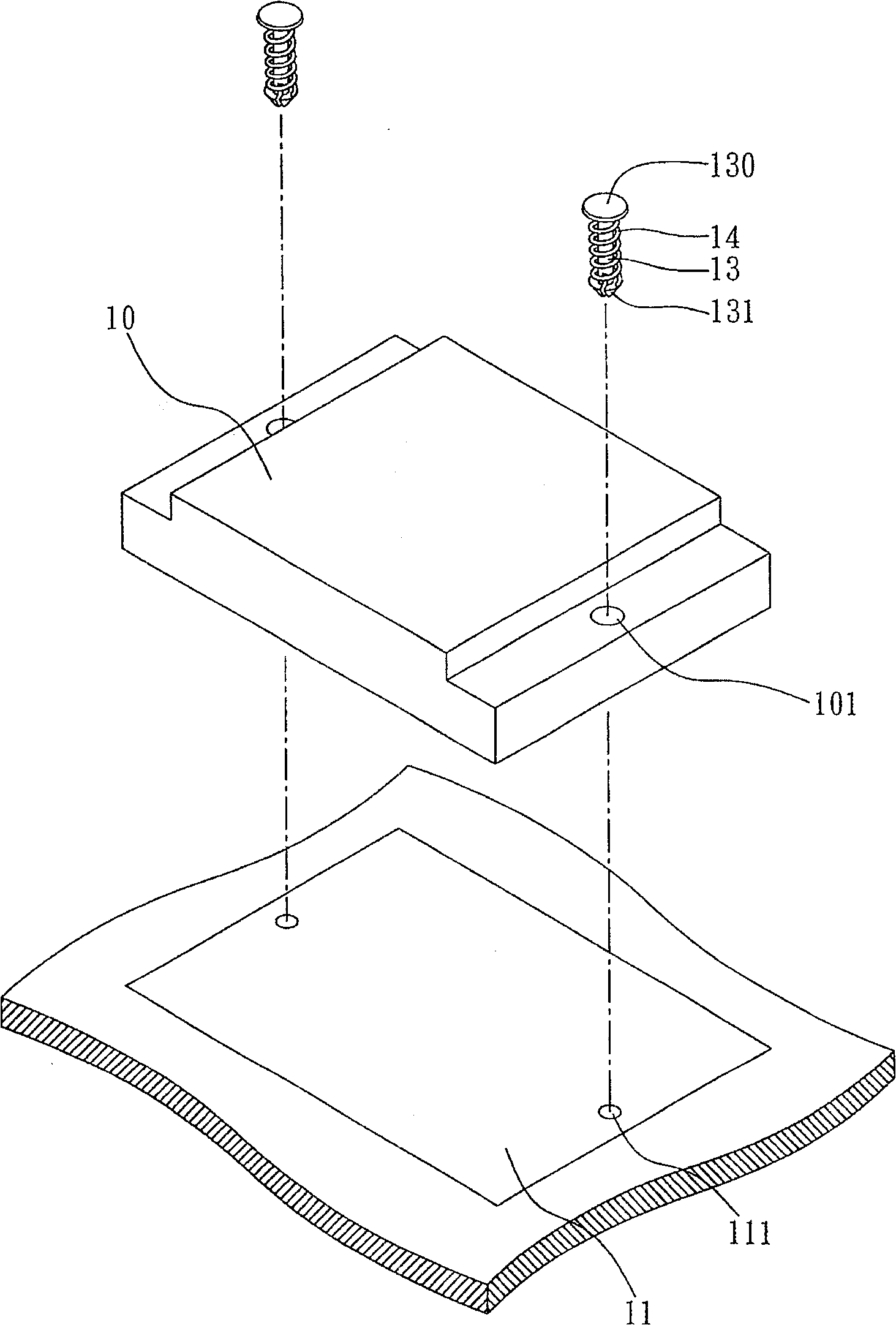

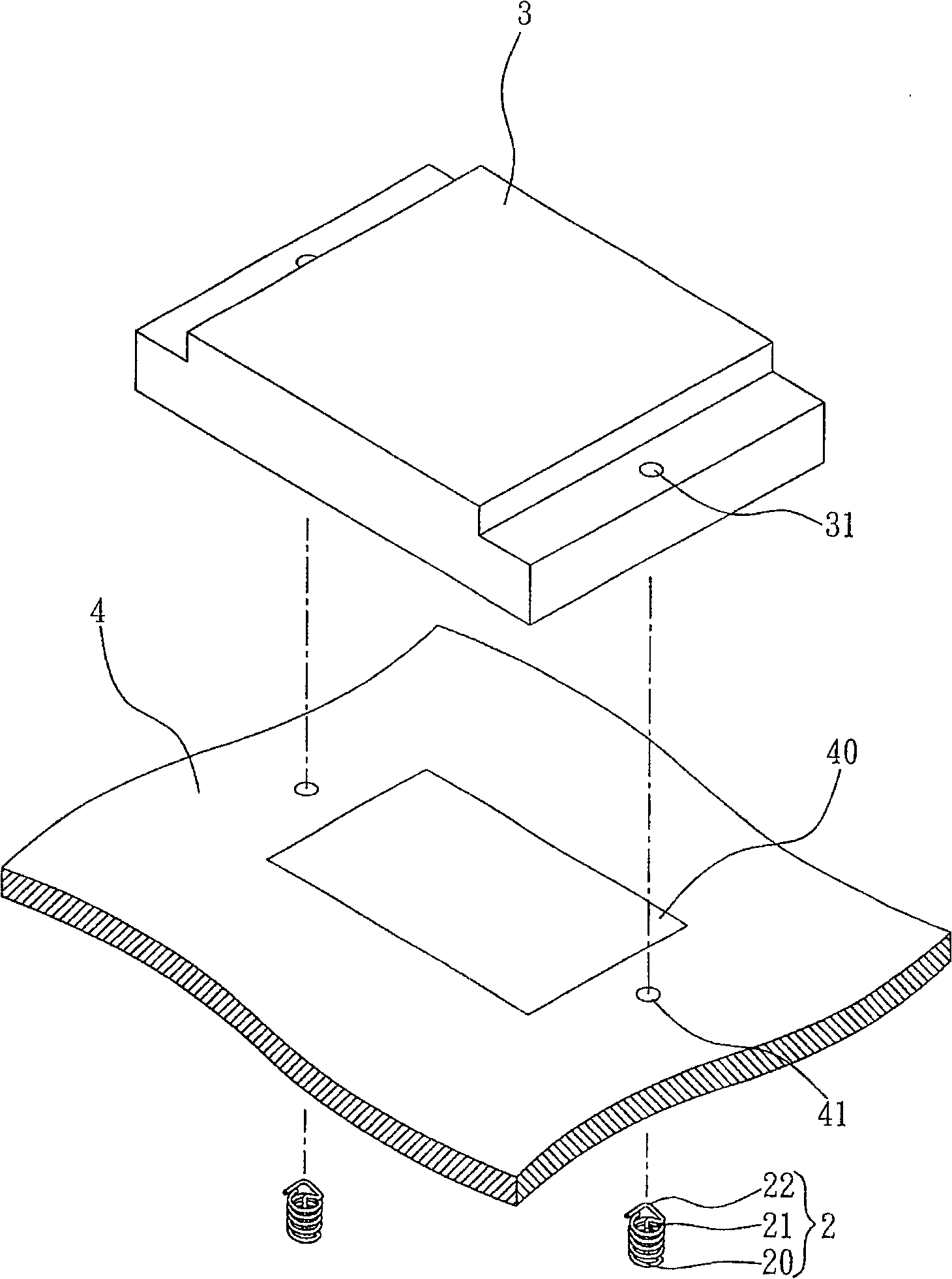

[0047] The following is a description of the implementation of the present invention through specific specific examples. Below, please describe the specific embodiments of the present invention with accompanying drawings, so that those with ordinary knowledge in the art can easily understand the technical features and effects of the present invention.

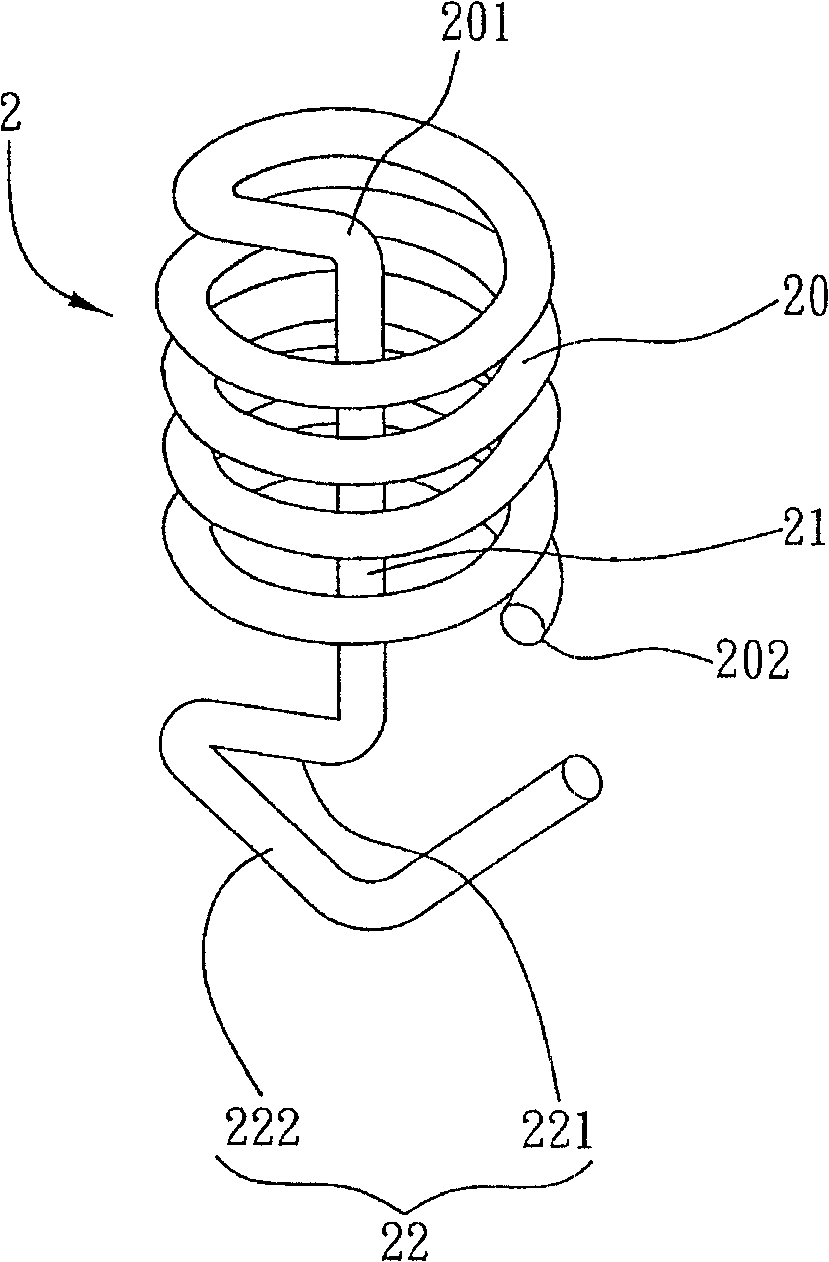

[0048] See figure 2 , The coupling member 2 of the present invention includes: an elastic coil 20 having a first end 201 and a second end 202; an extension wire 21 extending from the end of the first end 201 of the elastic coil to the first end of the elastic coil 20 Two ends 202; and a hook portion 22, connected to the extension wire 21 and located outside the second end 202.

[0049] The elastic coil 20, the extension wire 21, and the hook portion 22 of the coupling member 2 can be integrally formed with a metal wire, wherein the hook portion 22 is elastically deformable, and is horizontally bent on the abutment rod of the extensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com