Negative magnetoconductivity material with suitable thickness ring structure

A negative magnetic permeability material and appropriate technology, applied in waveguide devices, optics, instruments, etc., can solve the problems of not considering the influence of ring thickness resonance and inability to generate magnetic resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

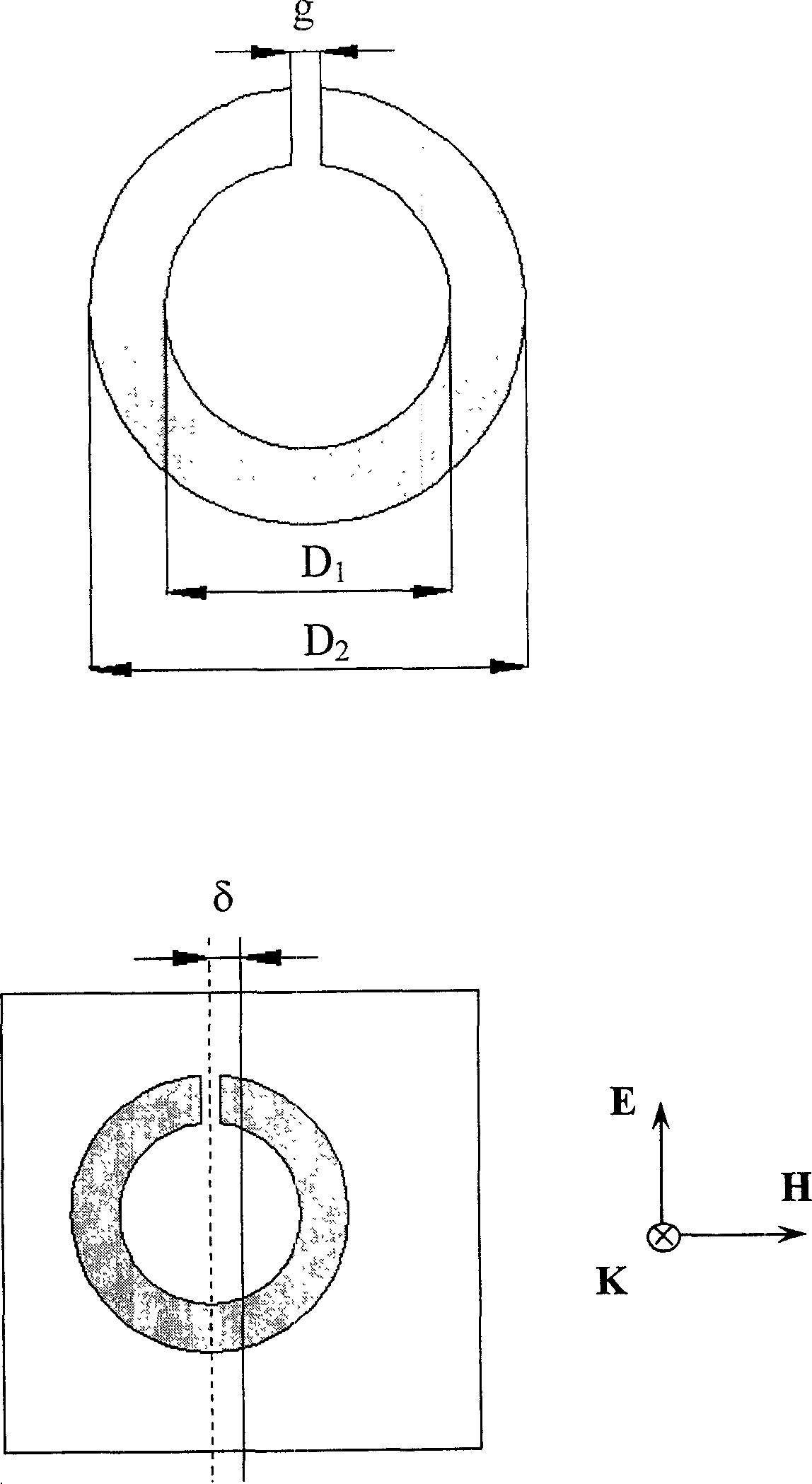

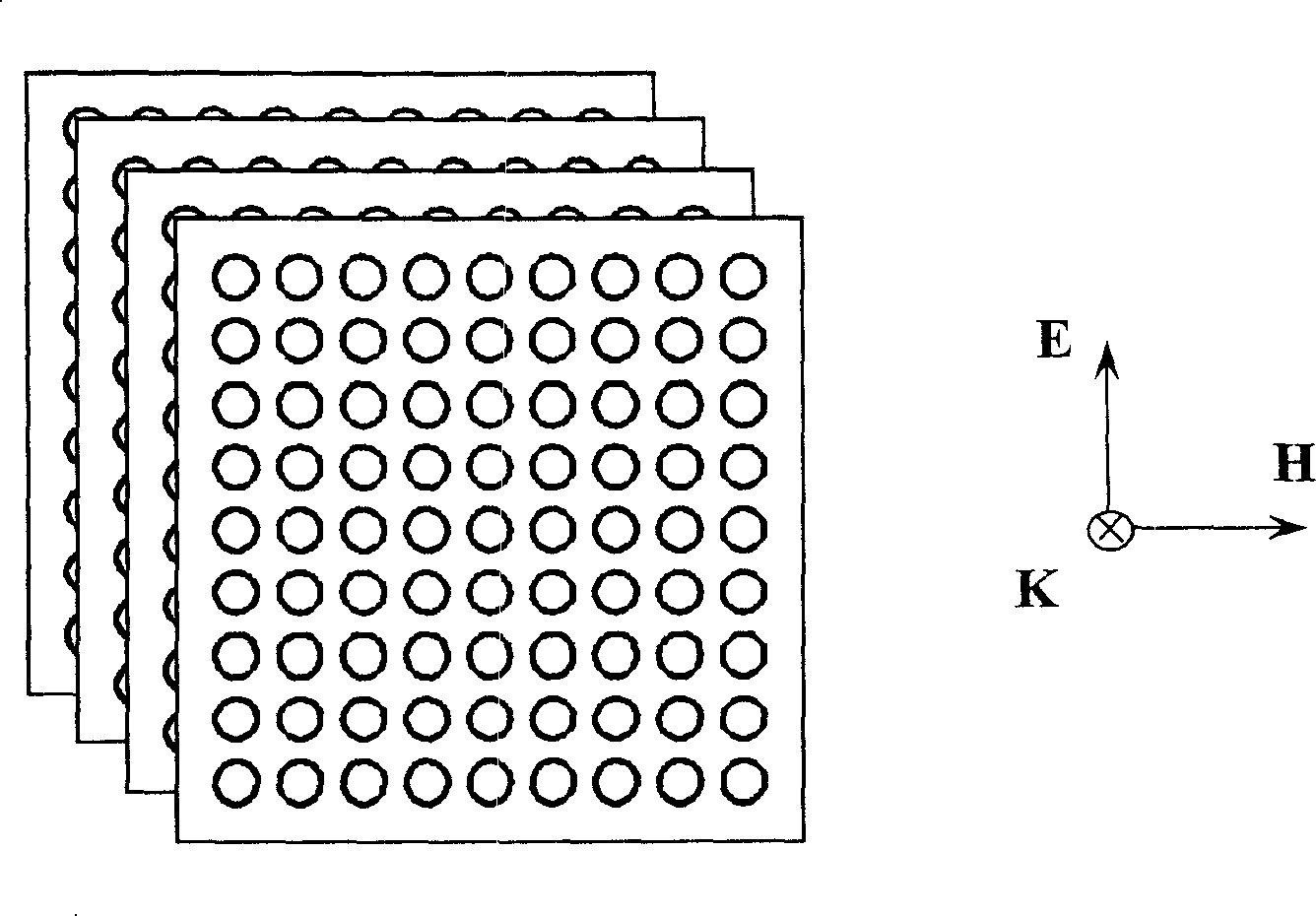

[0014] A metal copper closed ring with appropriate thickness is prepared by mechanical finishing method, and its structural parameters are: inner diameter D 1 8.0mm~32.0mm, outer diameter D 2 It is 10.0mm~35.0mm, and the thickness d is 1.0mm. It is fixed on the epoxy phenolic glass fiber medium substrate. The copper rings with the same geometric parameters are arranged in a layered structure according to a certain lattice periodic structure. The plane where the rings are located is parallel to The direction of the magnetic field is perpendicular to the direction of the wave vector, that is, a negative magnetic permeability material with an appropriate thickness ring structure is produced, and its resonance frequency is 900MHz-12000MHz.

Embodiment 2

[0016] A metal copper closed ring with appropriate thickness is prepared by mechanical finishing method, and its structural parameters are: inner and outer diameter D 1 / D 2 (unit: mm) take the values of 6 / 8, 4 / 6, 3.5 / 5, 2.5 / 4, 1.5 / 3, and the thickness d is 1.0mm, and fix it on the epoxy phenolic glass fiber medium substrate. The same geometric parameters The copper rings are arranged into a layered structure according to a certain lattice periodic structure. The plane of the rings is parallel to the direction of the magnetic field and perpendicular to the direction of the wave vector, that is, a negative magnetic permeability material with a ring structure of appropriate thickness (as shown in the attached figure 2 shown). The measured resonant frequencies are 14.5GHz, 15.2GHz, 16.7GHz, and 17.5GHz, respectively.

Embodiment 3

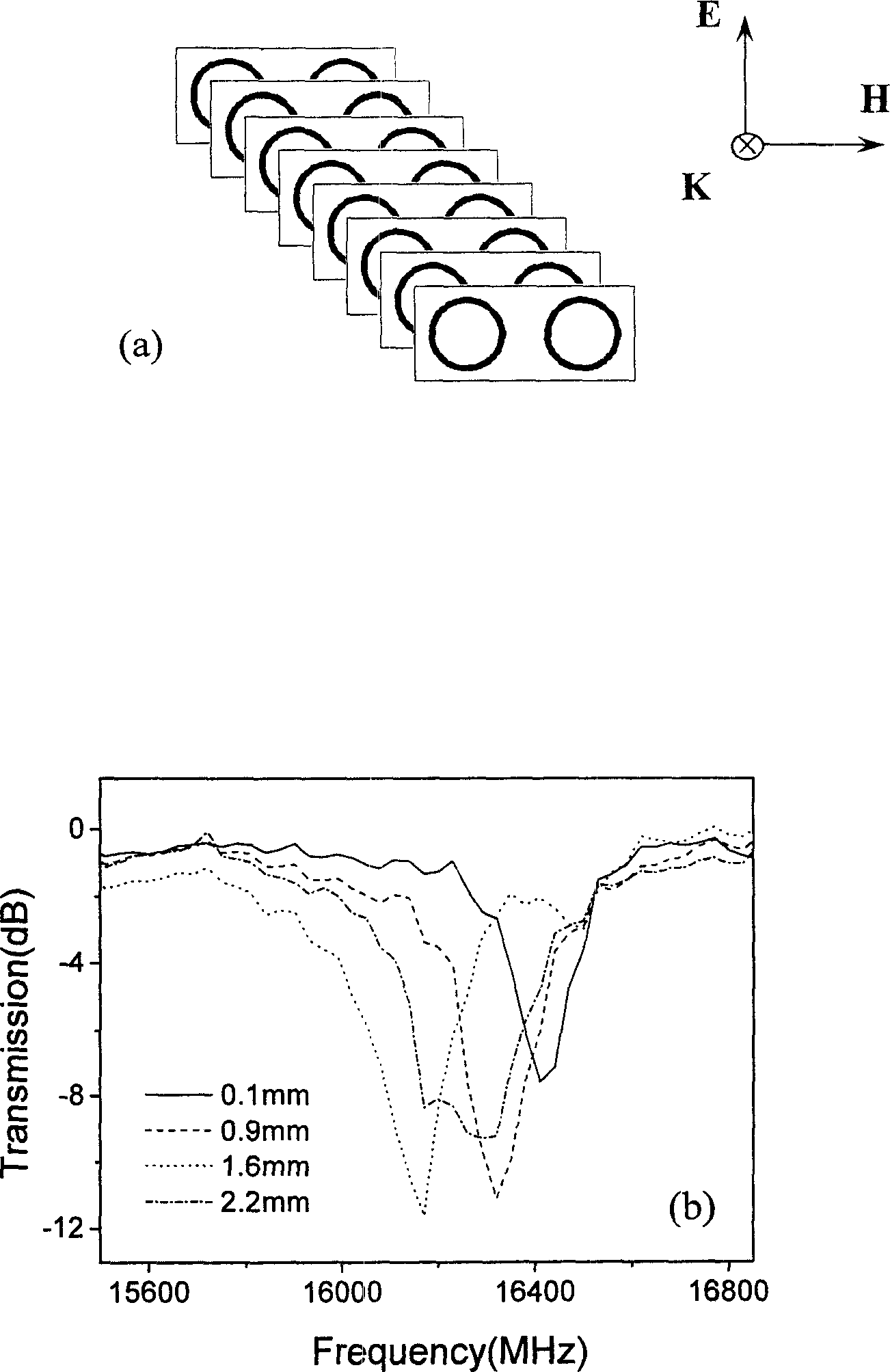

[0018] A metal copper split ring with appropriate thickness is prepared by mechanical finishing method, and its structural parameters are: inner diameter D 1 =2.5mm, outer diameter D 2 = 4.0mm, opening g = 0.1mm ~ 1.0mm, fix it on the epoxy phenolic glass fiber medium substrate, and arrange the copper rings with the same thickness d into a layered structure according to the interval of 5mm, that is, the ring structure with a certain thickness is obtained materials with negative magnetic permeability. Place it in the waveguide so that the plane of the ring is parallel to the direction of the magnetic field, that is, perpendicular to the direction of the wave vector, and measure the electromagnetic response behavior of the material. The results show that opening the ring can increase the resonant frequency of the material, and the adjustment range is 200MHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com