Magnetic source power machine

A power machine and magnetic power technology, applied in the field of magnetic source power machines, can solve problems such as resource consumption and environmental impact, and achieve the effects of short manufacturing cycle, less investment and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

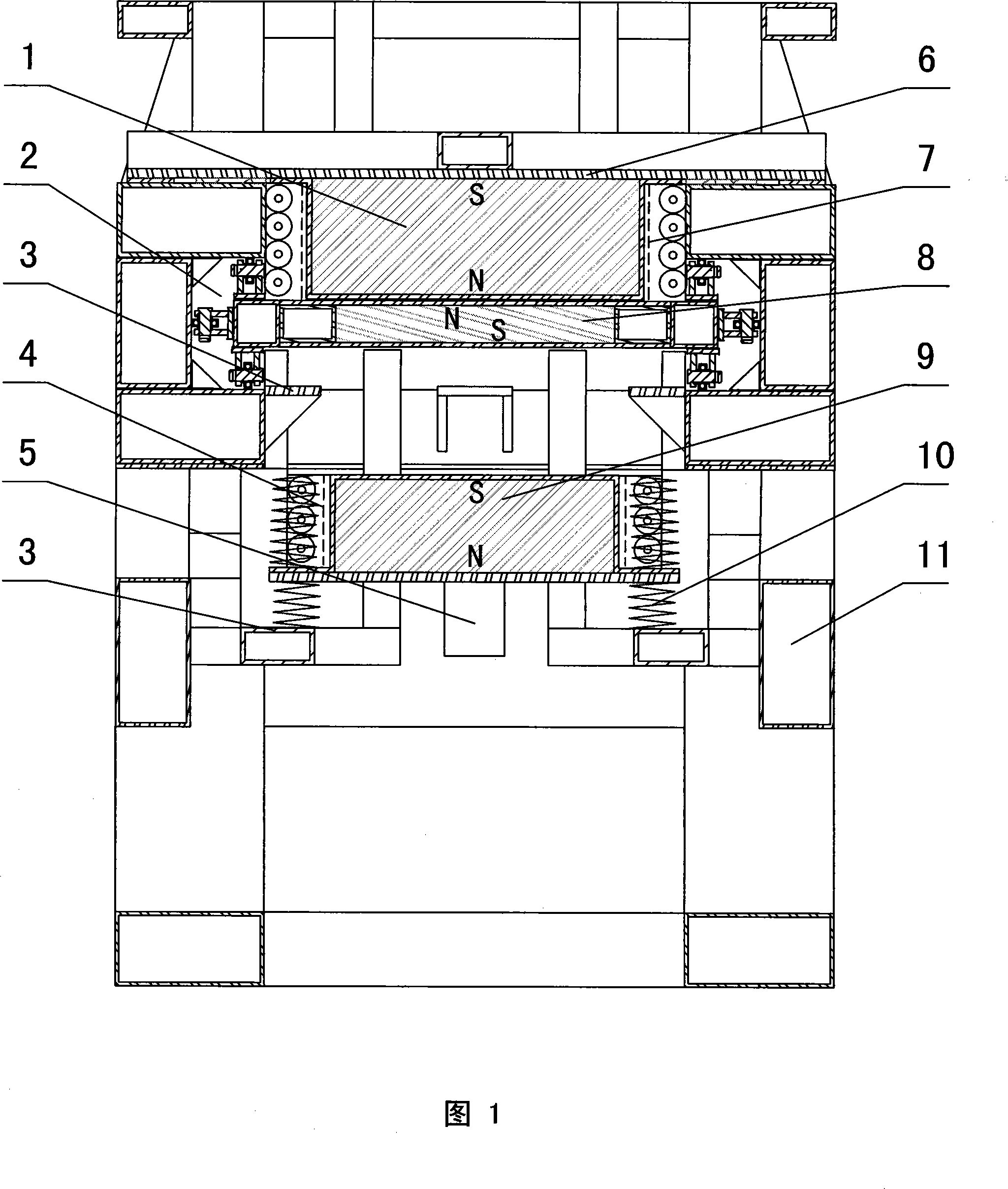

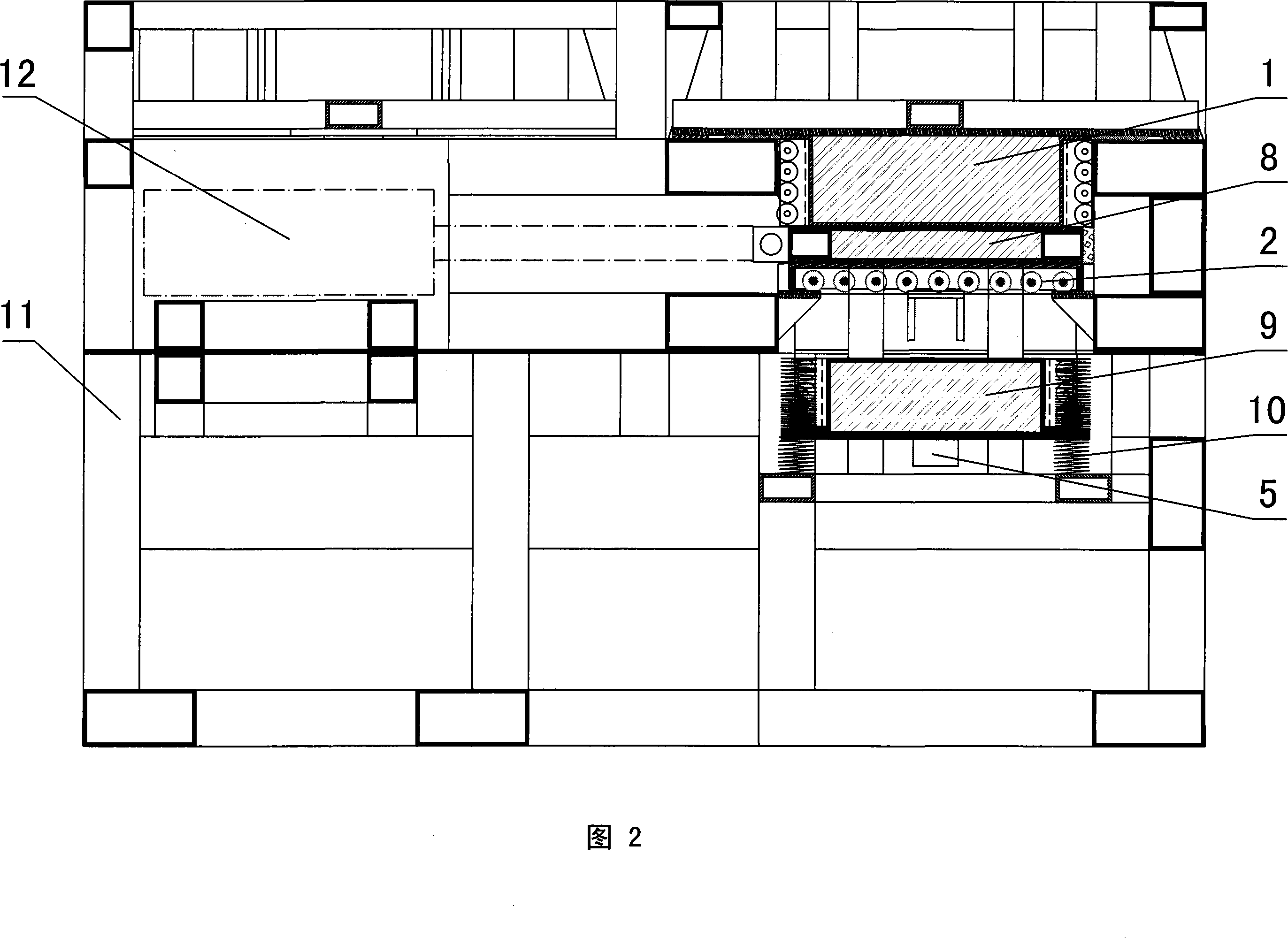

[0016] In the embodiment 1 shown in Figure 1 and Figure 2, the magnetic source power machine is composed of a frame 11, which is composed of a magnetic power group consisting of an upper magnet 1, a lower magnet 9 and a magnetic isolation plate 8, etc. The power groups are arranged in pairs, and a pneumatic starting device 12 is provided between the magnetic power groups, and the magnetic isolation plates 8 are connected to each other through the starting device. 8 out. The frame 11 is made of stainless steel with extremely low magnetic permeability. The frame 11 is provided with an upper slideway 7, a slideway 4 and a horizontal slideway 2. The upper magnet 1 is arranged in the upper slideway 7, and the lower magnet 9 is arranged in the slideway. In track 4, the upper and lower magnets are set with mutually attracting polarities. The magnetic isolation plate 8 is arranged in the horizontal slideway, and the polarities between the magnetic isolation plate 8 and the upper and ...

Embodiment 2

[0018] Upper magnet 1, lower magnet 9 and magnetic isolation plate 8 that embodiment 2 adopts are all electromagnets, and the insertion and extraction of magnetic isolation plate 8 are controlled by electric starting device 12, and all the other are the same as embodiment 1.

[0019] When the magnetic source power machine is working, the upper magnet and the lower magnet are respectively at the farthest points of the upper and lower slideways, and at the same time, the magnetic isolation plate is in a magnetic isolation state between the upper and lower magnets. Pull out the middle of the magnet, at this time the upper magnet slides to the lowest point of the upper slideway, the lower magnet moves up quickly along the slideway, and at the same time the upper end of the buffer spring starts to compress, when the buffer spring compression reaches the limit, the lower magnet reaches the rigidity of the upper end of the slideway Limiting device, this is the suction process of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com